Waste heat recovery biomass steam generator

A steam generator and waste heat recovery technology, which is applied in steam generation, steam boilers, steam boiler accessories, etc., can solve the problems of insufficient heat, unreasonable structure, and high exhaust temperature at the exhaust port, and achieve the effect of enhancing heat transfer. Improve the heat utilization rate and improve the effect of heat utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

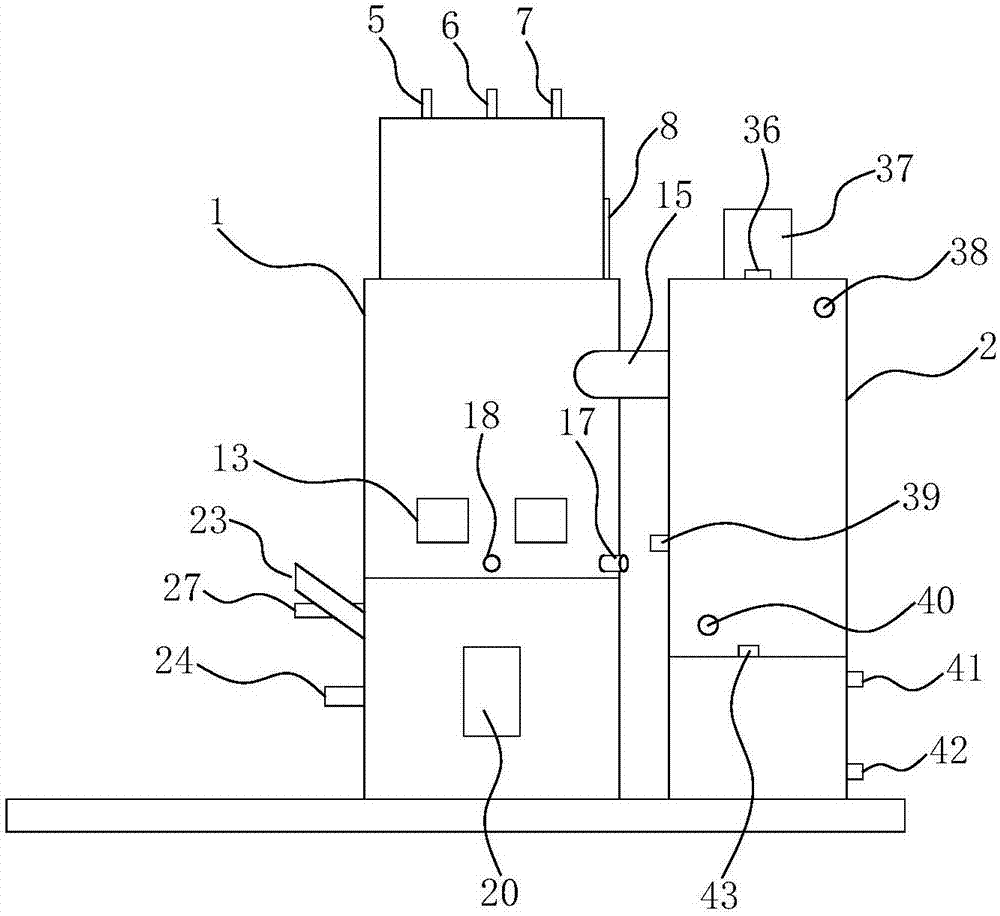

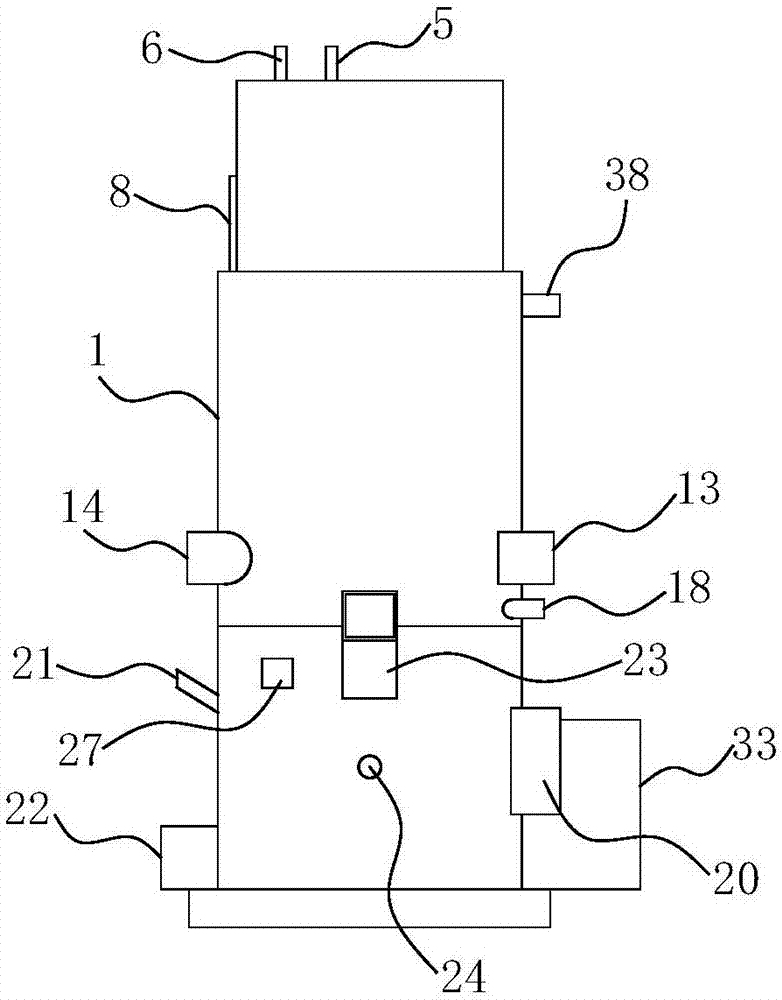

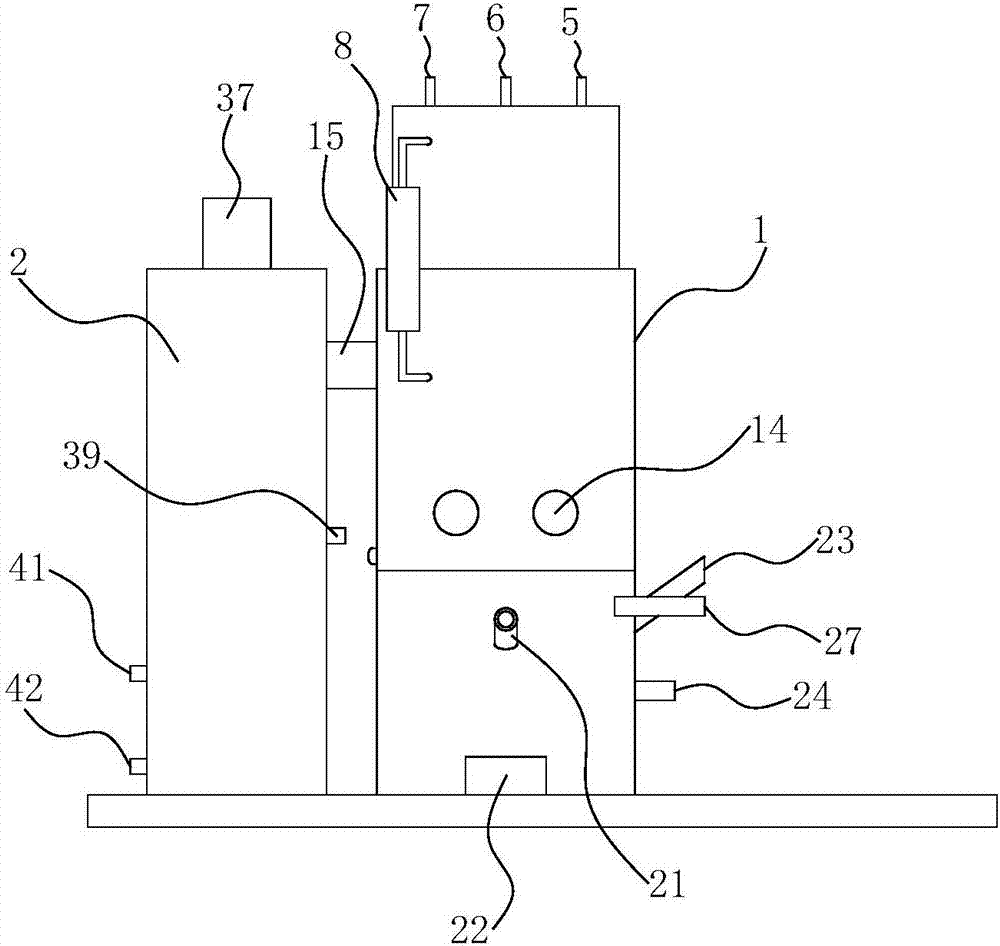

[0034] combine Figure 1-16 The waste heat recovery biomass steam generator shown includes a steam generator main body 1 and a waste heat recovery device 2 located on one side of the main body 1 . The waste heat recovery device 2 can be a commercially available conventional waste heat recovery device 2 . The waste heat recovery device 2 recovers waste heat from the flue gas passing through the main body 1, which makes the present invention more environmentally friendly and energy-saving, and at the same time can reduce the temperature of exhaust gas emission, greatly reducing the risk factor. The hot water produced after waste heat recovery can be directly used as domestic water, which is convenient to use. like Image 6As shown, the main body 1 includes a water exchange tank 3 on the upper part and a combustion chamber 4 on the lower part. The water exchange tank 3 is used as a place for heat exchange between high-temperature flue gas and water, and the combustion chamber 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com