Energy-saving combustion heat supplying network optimizing system

A technology of network optimization and combustion heating, which is applied in heating systems, hot water central heating systems, and combustion air/fuel supply, etc. Advanced problems, to achieve the effect of improving heat exchange efficiency, saving costs, and reducing volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

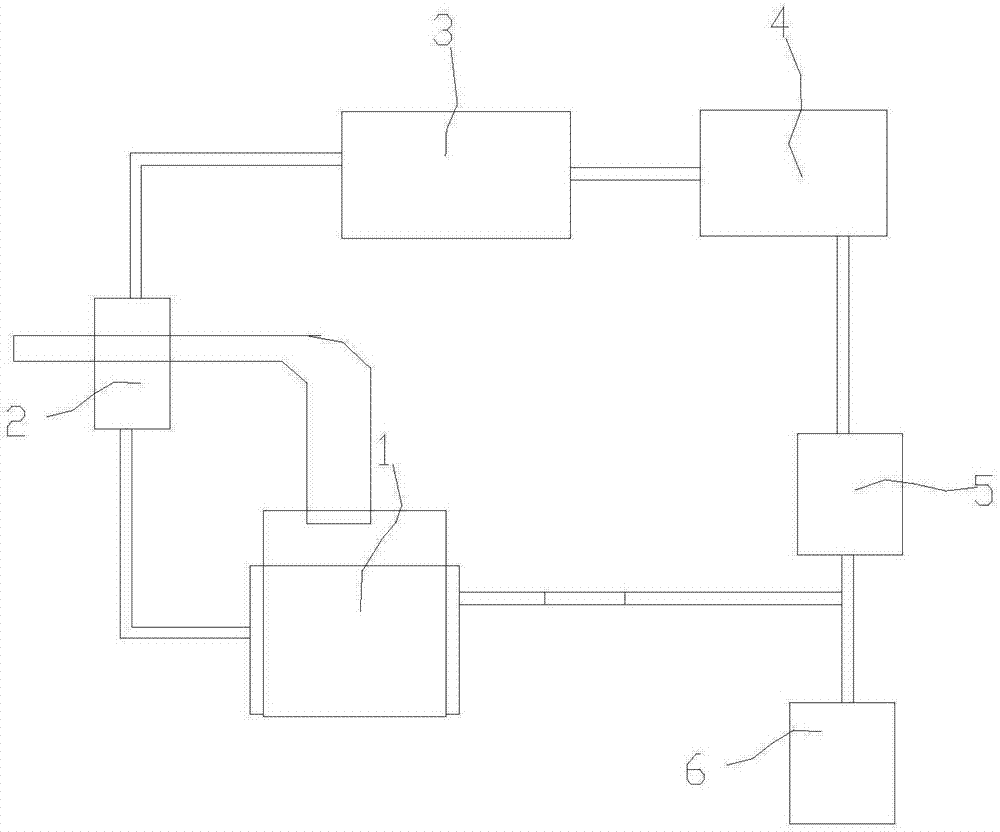

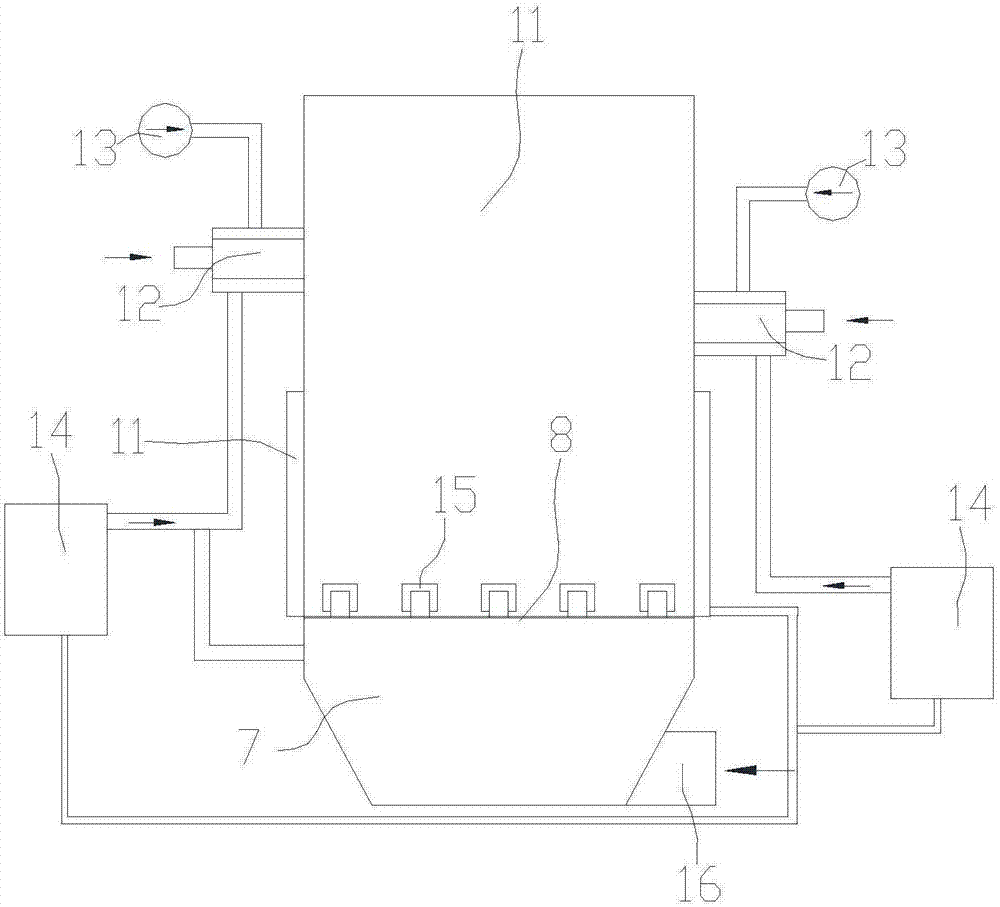

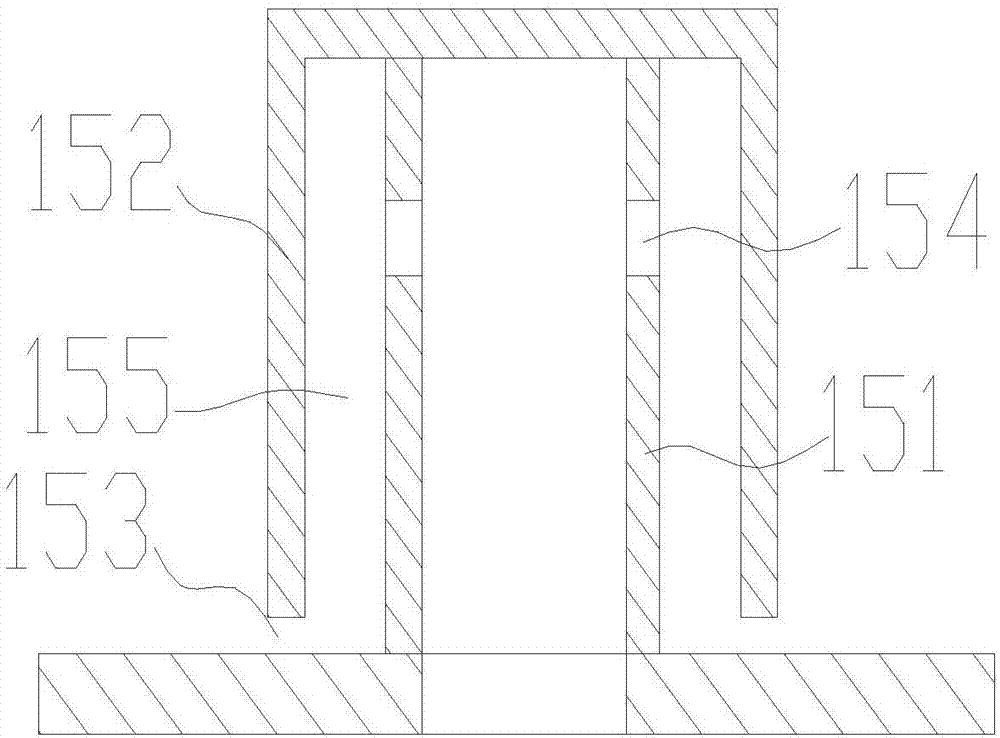

[0030] An energy-saving combustion heating network optimization system, such as figure 1 what Figure 6 As shown, it includes a steam boiler 4, a biomass gasification furnace 1 and a heat exchange pipe network 3, and the cold water pipe is connected to the first heat exchanger 2 after being preheated through the outer jacket of the biomass gasification furnace 1, and the first heat exchanger 2 The heater 2 is connected to the exhaust gas pipe of the biomass gasification furnace 1, and is used to make full use of the exhaust waste heat of the biomass gasification furnace 1 to reheat the water; the heat exchanger 1 is connected to the heat exchange The pipe network 3 is connected, the heat exchange pipe network 3 is connected to the steam boiler 4, the steam boiler 4 is connected to the combustion device 12, and the combustion device 12 is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com