Unmanned aerial vehicle measuring instrument

A measuring instrument and unmanned aerial vehicle technology, which is applied in the field of unmanned aerial vehicle measuring instruments, can solve the difficulties in the normal laying out, positioning, pointing and other construction work of the laser pointing instrument, unevenness or other obstacles on the ground, and worker labor. In order to improve the efficiency of measurement and construction, reduce the labor intensity of workers and achieve the effect of compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

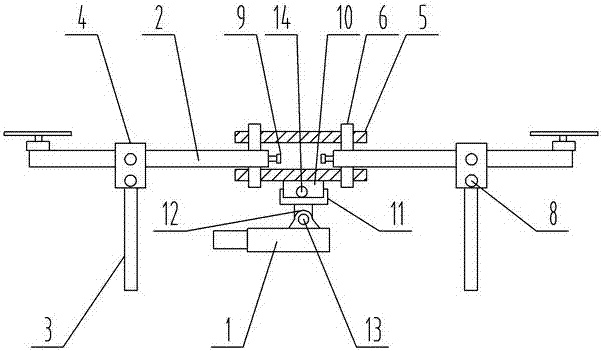

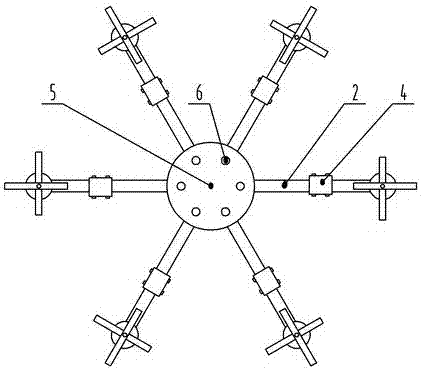

[0022] see Figure 1-4 , among the figures, the unmanned aerial vehicle surveying instrument of the present invention includes an unmanned aerial vehicle carrying a laser pointing instrument 1, and a PLC remote controller.

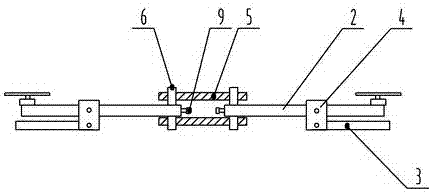

[0023] Among them, the UAV includes six arms 2 and six legs 3, as well as a driver, a card board assembly and a U-shaped splint 4 corresponding to the number of legs, wherein the card board assembly includes two cards arranged in parallel up and down. Plate 5, and pin shafts for fixedly connecting the upper and lower clamps, each support arm is distributed radially along the circumference of the clamps, and one end of the support arm is hinged between the upper and lower sides of the two clamps through the pin shaft 6, for connecting the upper and lower clamps The pin shaft of clamping plate is shared with the pin shaft of support arm and clamping plate hinge, and the top of each U-shaped splint is sheathed on each support arm continuously, and one end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com