Hyperspectral imaging based non-destructive quantitative testing device for mixture powder and method

A hyperspectral imaging and quantitative detection technology, applied in the field of machine vision and hyperspectral imaging, can solve the problems of difficulty in detection, high requirements for sample stability, no stable powder mixture, accurate detection, etc., to achieve high resolution and high freedom. degree, the effect of the modularization of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

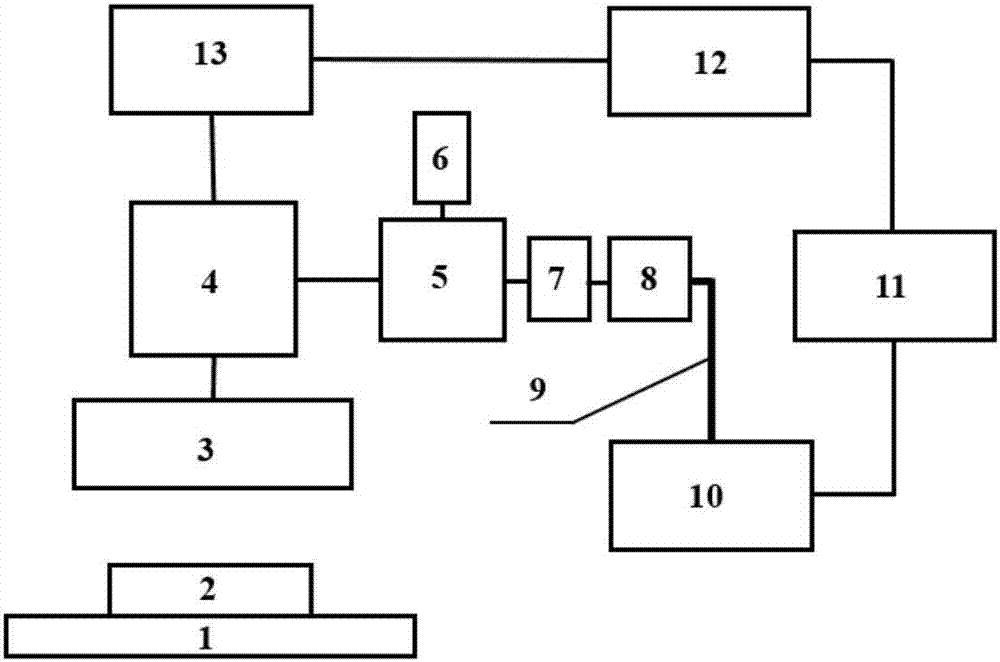

[0044] Such as figure 1 As shown, the novel hyperspectral imaging system proposed by the present invention consists of four parts: excitation module, scanning module, signal acquisition module and control driving module.

[0045] The excitation module of the present invention is composed of an excitation light source and a dichroic mirror or a half mirror. The system has a high degree of freedom and can be applied to different spectral imaging modes. When the system works in near-infrared and infrared hyperspectral imaging modes, a combination of broad-spectrum light source and half-transparent mirror is used. When the system works in fluorescence and Raman hyperspectral imaging mode, a combination of laser light source and dichroic mirror is used. Its function is to reflect the light source signal to the scanning module.

[0046] The scanning module of the present invention is composed of a two-dimensional vibrating mirror and a flat-field scanning lens. The two-dimension...

Embodiment 2

[0051] Hyperspectral imaging detection method adopted in the present invention:

[0052] (1) Sample preparation: After mixing the mixed powder sample to be tested evenly and pressing it flat, place it on the sample platform;

[0053] (2) Acquisition of hyperspectral signals: Determine the light source, half-mirror and dichroic mirror according to the required spectrum technology. Set the scanning range (detection area) and the number of scanning points (resolution), and set the integration time of single-point scanning according to the characteristics of the sample to be detected. Then start scanning, and record the spectral signal x collected by the spectrometer at each scanning point at the same time k , where k represents the number of variables contained in the spectral curve.

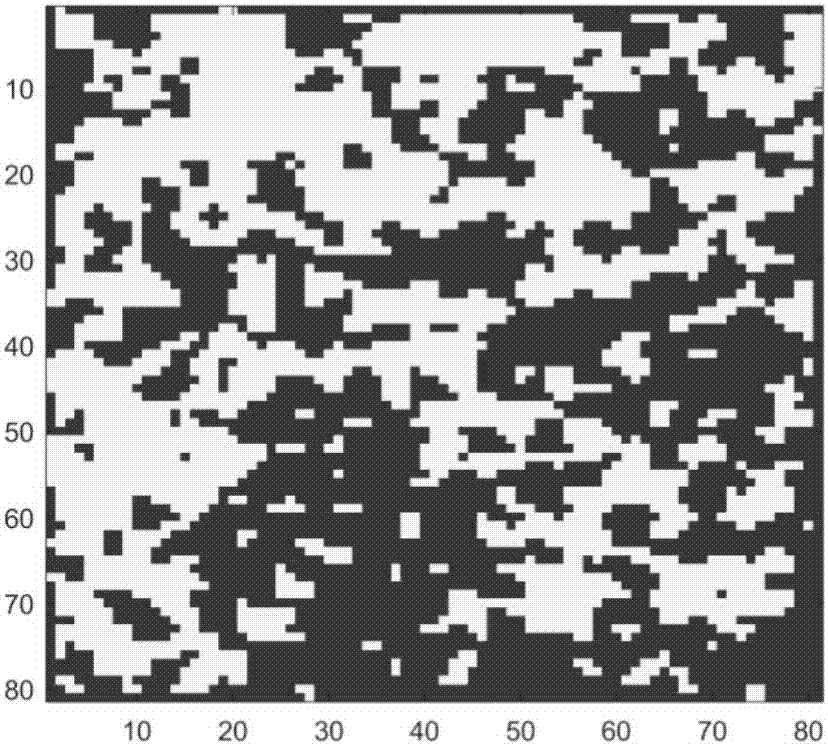

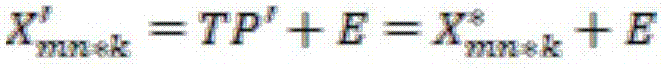

[0054] (3) Spectral preprocessing: for the collected three-dimensional spectral data X m*n*k Expand to two-dimensional data X mn*k . Among them, m and n respectively represent the number of ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com