Multichannel V-groove type optical coupling inserting core

An optical coupling, multi-channel technology, applied in the coupling of optical waveguides, light guides, optics, etc., can solve the problems of labor-hour cost and grinding consumables cost, surface material damage of guide pinholes, high cost, etc., to promote high density and low energy. Consumption, optimized structure, easy to repeat the effect of plugging and unplugging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

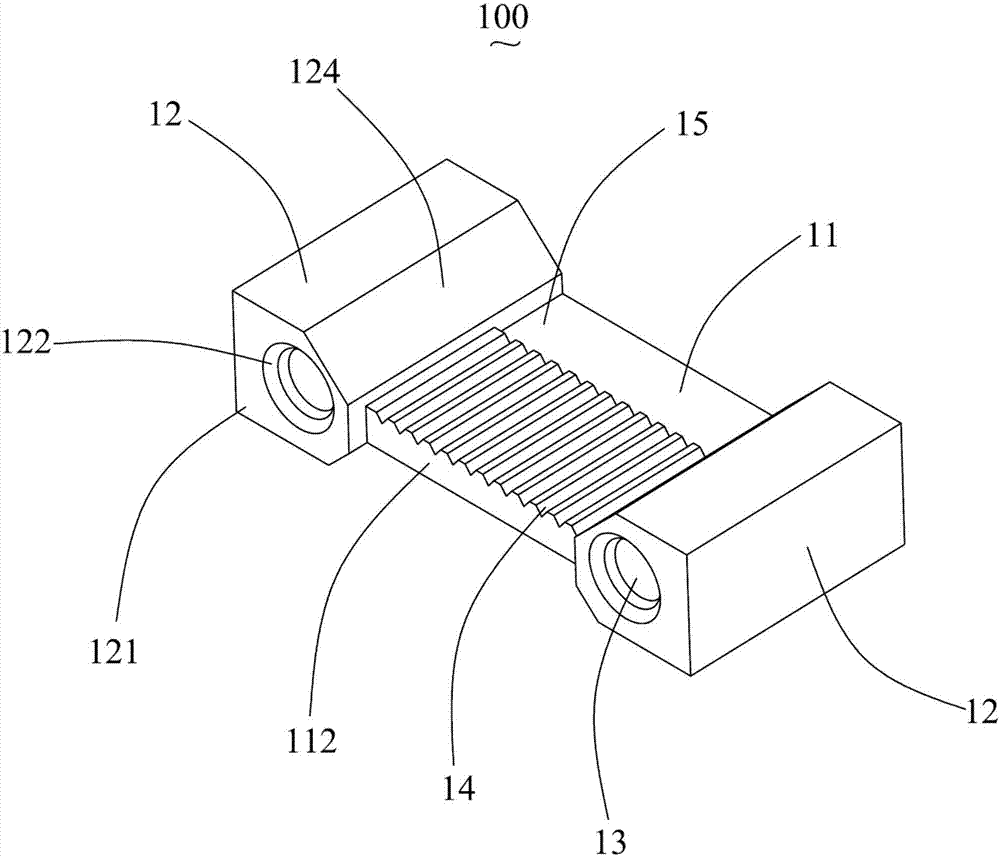

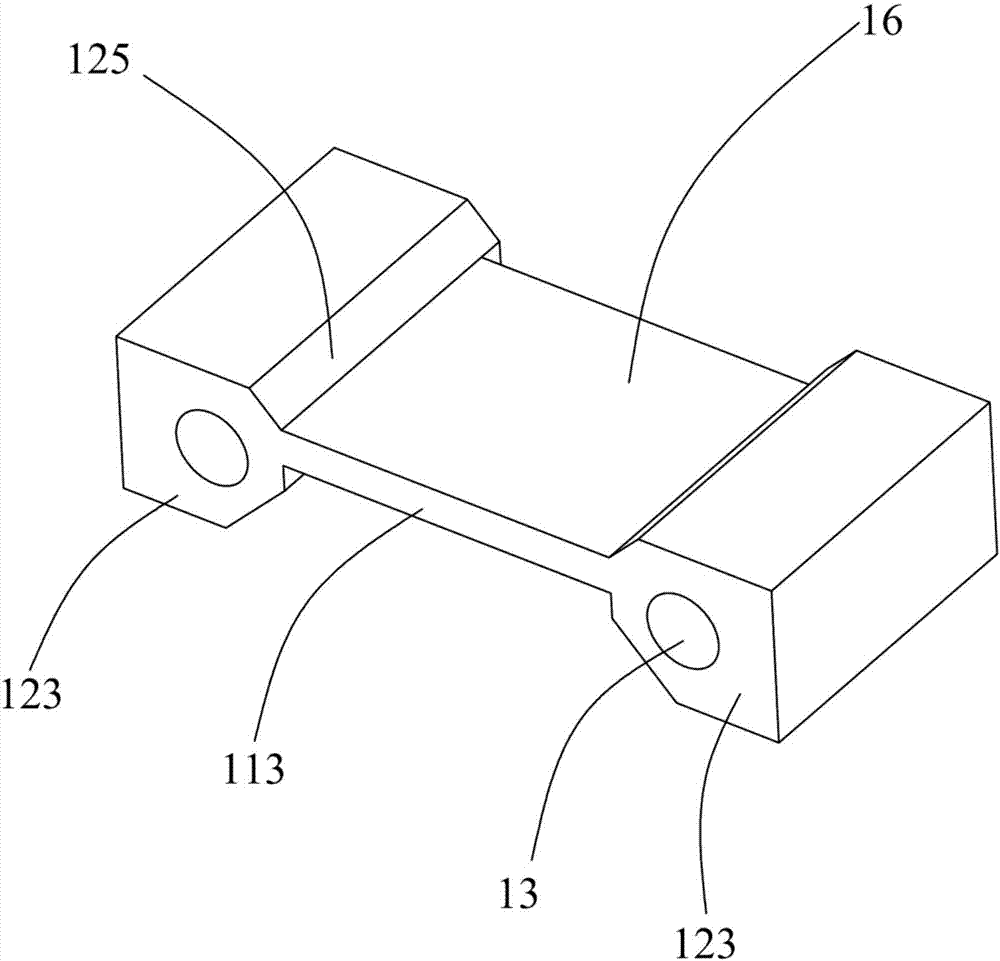

[0022] like Figure 1 to Figure 2 As shown, it is a multi-channel V-groove optical coupling ferrule 100 according to the present invention, which includes: an optical fiber hole plate 11 and two guide pin hole barrels 12 located on both lateral sides of the fiber hole plate 11, the guide pins The hole barrel 12 is provided with a guide pin hole 13 penetrating along the front and back direction, and the optical fiber hole plate 11 is provided with a row of fiber positioning holes 14 . The optical fiber hole plate 11 is recessed backwards relative to the two guide needle hole cylinders 12, so as to reserve a working distance for laser cutting.

[0023] The guide pin hole barrel 12 is provided with a front end surface 121 and a chamfered structure 122 located on the front end surface 121 of the guide pin hole barrel 12 . The thickness of the optical fibe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com