Positive electrode material used for lithium-iodine battery

A positive electrode material and battery technology, applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of easy volatilization, increasing difficulty, and low Coulombic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

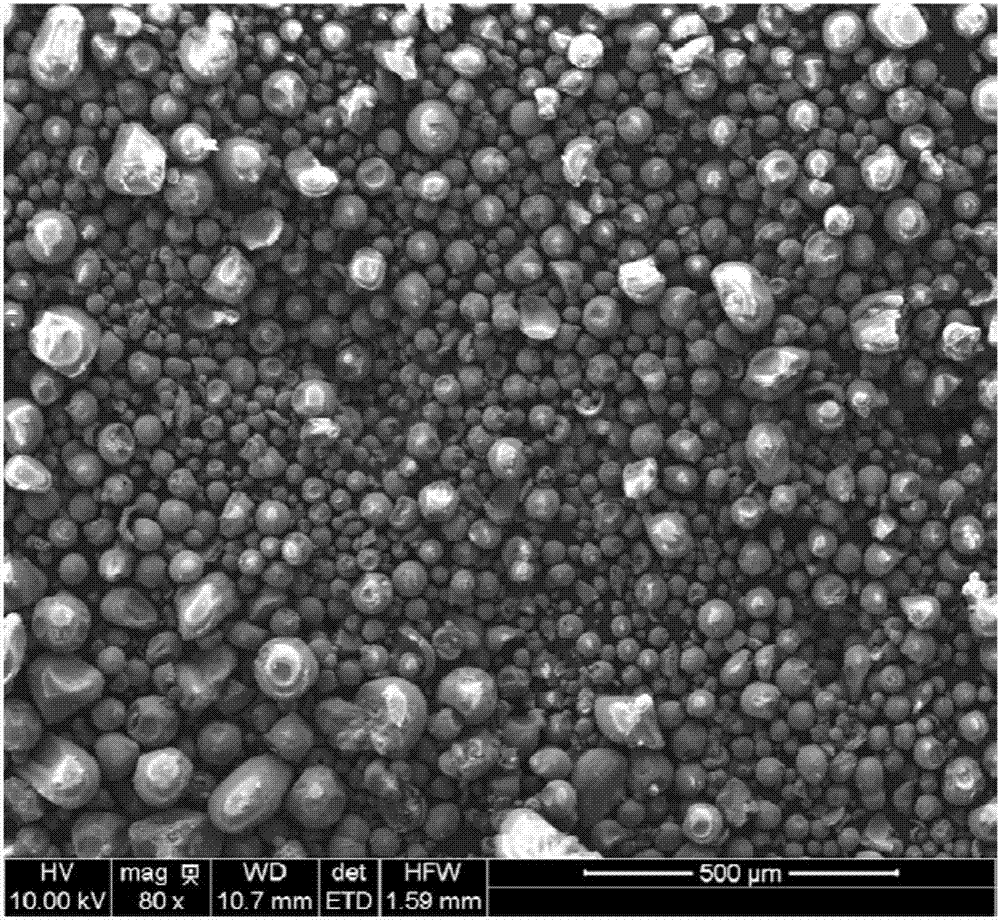

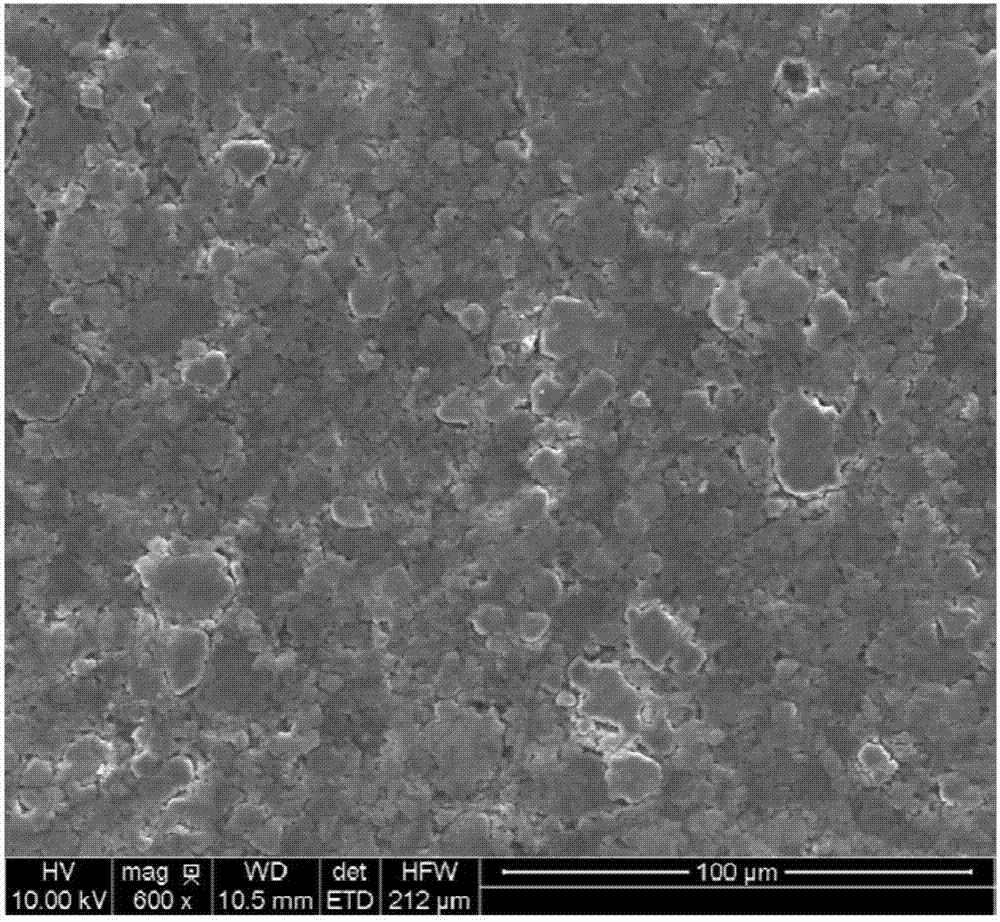

[0046] Positive electrode preparation: PVP-I 2 0.5g, Ketjen black 0.2g, reduced graphene oxide 0.02g ball mill and mix evenly. Take 0.15g of the above mixture and 0.026g of PTFE, and after thorough grinding, prepare a positive electrode. From figure 1 It can be seen that the purchased PVP-I 2 It is granular, ranging in size from tens of microns to hundreds of microns. From figure 2 It can be seen that the prepared cathode materials are mixed uniformly.

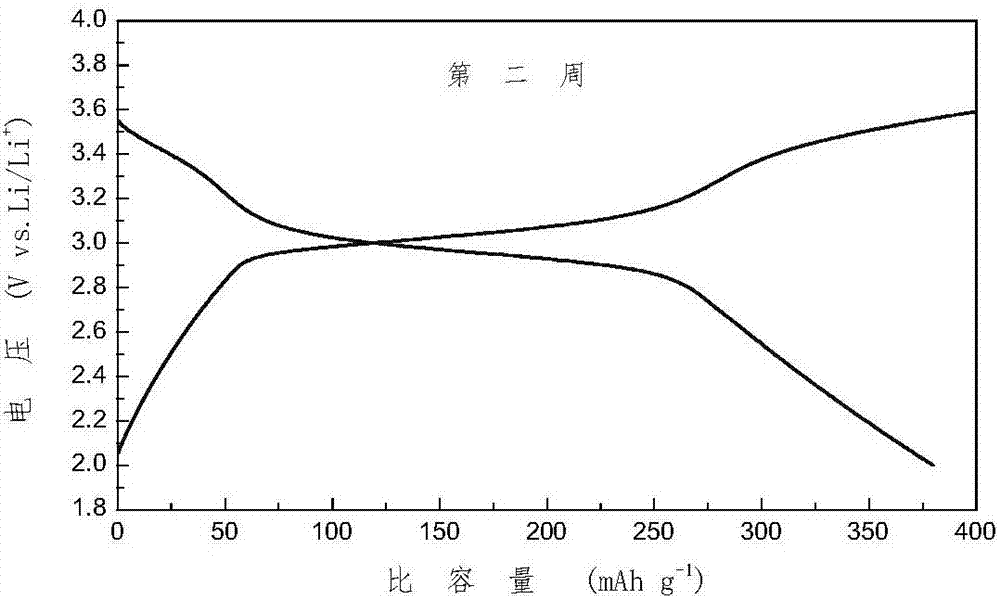

[0047] Battery assembly: The above-mentioned positive electrode material is directly used as a battery pole piece to assemble a lithium battery. The voltage-capacity diagram of the material in the second cycle of charging and discharging at 0.2C is as follows image 3 shown. It can be seen from the figure that the discharge curve of the material has two discharge plateaus. The first platform is between 3.3-3.4V, and the second platform is around 2.9V. The charge-discharge cycle performance of the material at 0.5C is...

Embodiment 2

[0049] Positive electrode preparation: 1.2g PVP-I 2 Dissolved in 8ml of ethanol, prepared as solution A. After immersing the purchased carbon cloth in solution A for 12 h, the carbon cloth was taken out and vacuum-dried at room temperature to obtain the positive electrode material. From Figure 5 It can be seen that PVP-I 2 Uniformly attached to the surface of the carbon cloth or in the holes.

[0050] Battery assembly: The above-mentioned positive electrode material is directly used as a battery pole piece to assemble a lithium battery. The charge-discharge cycle performance of the material at 0.5C is as follows: Figure 6 shown. It can be seen from the figure that the initial discharge specific capacity of the material is 180mAh g -1 Above, after 500 cycles, its discharge specific capacity still remains at 100mAh g -1 above. In addition, its Coulombic efficiency is maintained above 99%, indicating that the shuttle effect of polyiodide anions generated during charge a...

Embodiment 3

[0052] Positive electrode preparation: PVP-I 2 0.5g, superconducting carbon black 0.2g ball mill and mix evenly. Take 0.15g of the above mixture and 0.05g of PTFE, and after thorough grinding, prepare a positive electrode.

[0053] Battery assembly: The above-mentioned positive electrode material is directly used as a battery pole piece to assemble a lithium battery.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com