Construction method of waterproofing and heat preservation integrated compound system

A construction method and technology of a composite system, applied in the direction of roof insulation materials, coatings, roof coverings, etc., can solve the problems of many processes, long construction period, poor thermal insulation effect, etc., saving building materials, reducing construction difficulty, The effect of shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

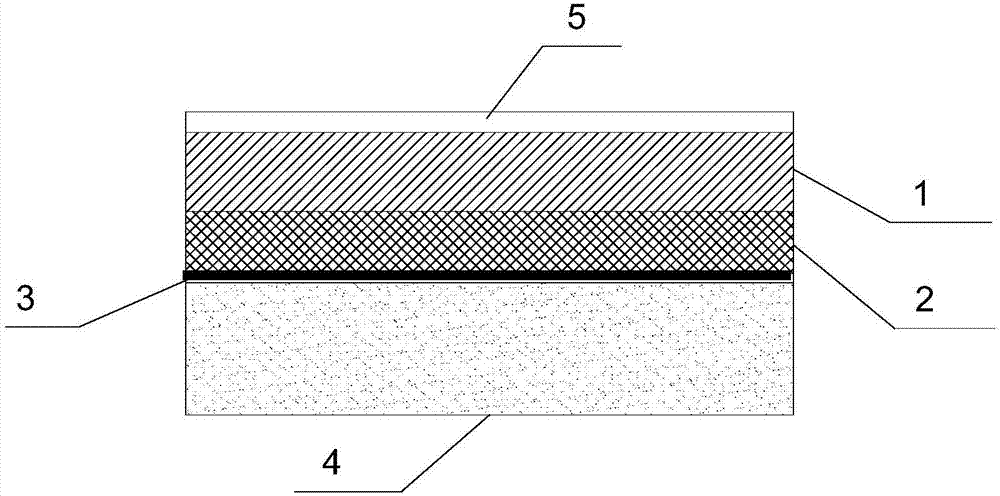

[0025] see figure 1 , a construction method of a waterproof and thermal insulation integrated composite system, comprising the following steps:

[0026] ①Clean up the base layer 4;

[0027] 2. Brushing the waterproof layer 3, the waterproof layer 3 is a polymer waterproof coating; the polymer waterproof coating comprises the following raw materials in parts by weight and is made: 2 parts of molybdenum oxide, 10 parts of polyethylene, and 8 parts of polyacrylate emulsion , 3 parts of tackifier, 10 parts of propionaldehyde resin, 4 parts of terpene resin, 2 parts of p-chloromethyl styrene, 3 parts of methyl acetate; The preparation method of described polymer waterproof coating comprises the following steps: one, Add polyethylene, polyacrylate emulsion, propionaldehyde resin, terpene resin, and p-chloromethylstyrene into the stirring mixer, heat and stir at 65 degrees Celsius for 0.5 hours, then add a tackifier, and heat up to 95 degrees Celsius. Stirring speed is 135 rpm, mix...

Embodiment 2

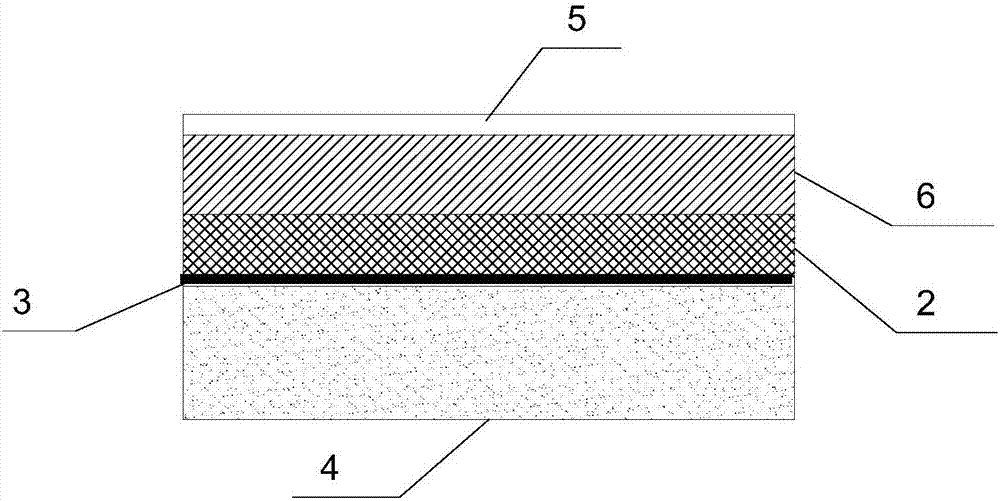

[0032] see figure 2 , a construction method of a waterproof and thermal insulation integrated composite system, comprising the following steps:

[0033] ①Clean up the base layer 4;

[0034] 2. Brushing the waterproof layer 3, the waterproof layer 3 is a polymer waterproof coating; the polymer waterproof coating comprises the following raw materials in parts by weight and is made: 8 parts of molybdenum oxide, 12 parts of polyethylene, 11 parts of polyacrylate emulsion , 5 parts of tackifier, 12 parts of propionaldehyde resin, 8 parts of terpene resin, 8 parts of p-chloromethyl styrene, 8 parts of methyl acetate; The preparation method of described polymer waterproof coating comprises the following steps: one, Add polyethylene, polyacrylate emulsion, propionaldehyde resin, terpene resin, p-chloromethyl styrene into the stirring mixer, heat and stir at 88 degrees Celsius for 2 hours, then add tackifier, raise the temperature to 100 degrees Celsius, and stir The speed is 205 rp...

Embodiment 3

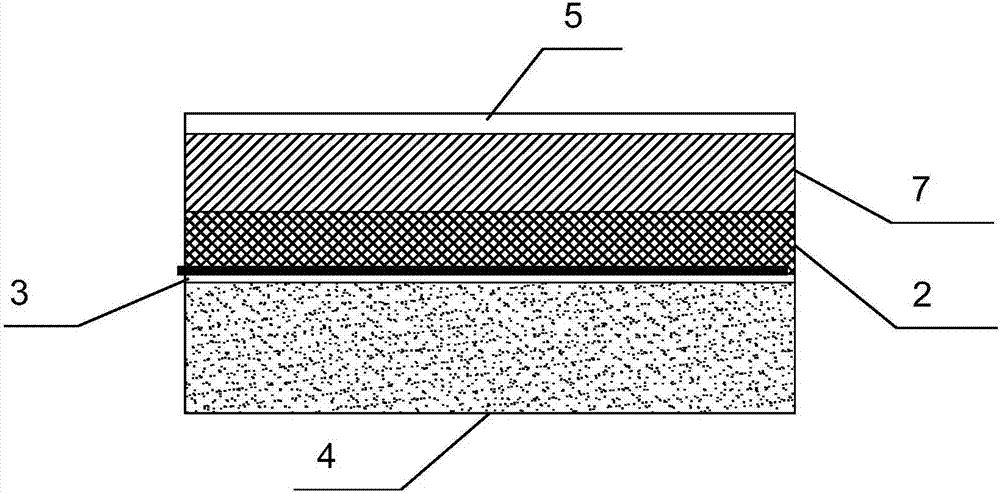

[0039] see image 3 , a construction method of a waterproof and thermal insulation integrated composite system, comprising the following steps:

[0040] ①Clean up the base layer 4;

[0041] 2. Brushing the waterproof layer 3, the waterproof layer 3 is a polymer waterproof coating; the polymer waterproof coating comprises the following raw materials in parts by weight: 6 parts of molybdenum oxide, 11 parts of polyethylene, 9 parts of polyacrylate emulsion , 4 parts of tackifier, 11 parts of propionaldehyde resin, 5 parts of terpene resin, 6 parts of p-chloromethyl styrene, 7 parts of methyl acetate; The preparation method of described polymer waterproof coating comprises the following steps: one, Add polyethylene, polyacrylate emulsion, propionaldehyde resin, terpene resin, and p-chloromethylstyrene into the stirring mixer, heat and stir at 75 degrees Celsius for 1 hour, then add tackifier, raise the temperature to 98 degrees Celsius, and stir The speed is 178 rpm, mixed and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com