Construction of ultra-sensitive electrochemiluminescence sensor and application thereof to aspect of trinitrotoluene detection

An electrochemistry and sensor technology, applied in the field of ultra-sensitive electrochemiluminescence sensors, can solve the problems of complex pretreatment process, huge equipment, limited application, etc., achieve good optical stability and thermal stability, small size, storage long time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

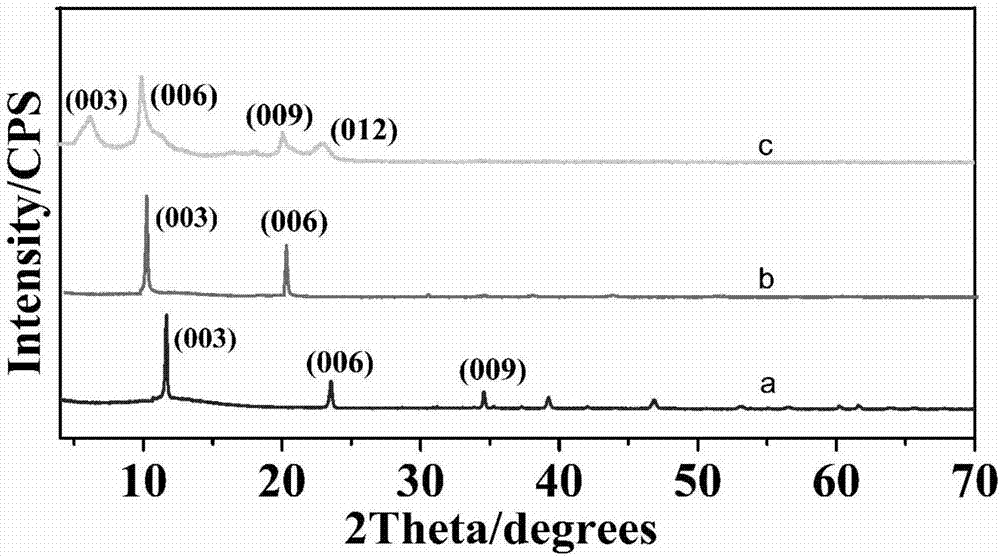

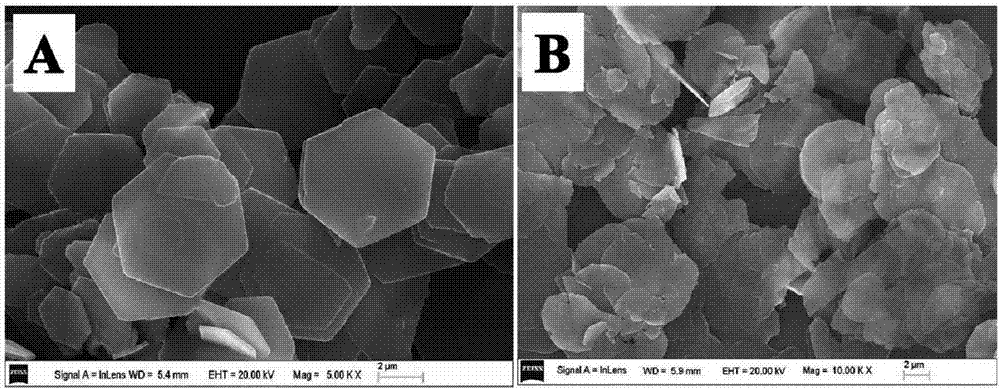

[0042] (1) Preparation of hydrotalcite precursor: weigh 2.33g CoCl 2 ·6H 2 O(10mM), 1.90g Al(NO 3 ) 3 ·6H 2 O (5mM) and 3.0g urea (30mM) were dissolved in 800ml of deionized water to obtain the mixed solution A of the three chemicals, poured the mixed solution A into a three-necked bottle, heated and stirred in an oil bath at 97°C for 48h, And carry out condensation and reflux, to obtain the solution B after the reaction. Then, the reacted solution B was centrifuged and washed several times until the pH value of the supernatant was less than 8, and then the precipitate R1 obtained after centrifugation and washing was dried at 70°C for 24 hours to obtain the hydrotalcite intermediate CoAl-CO 3 LDHs. After that, weigh 0.5gCoAl-CO 3 LDHs with 127.5g NaNO 3 Mix in 0.225ml to CO 2 water to obtain the mixed solution C, put the mixed solution C in a three-necked flask, and add 0.225ml of concentrated HNO 3 , under the protection of nitrogen, vigorously stirred the reaction ...

Embodiment 2

[0049] (1) With embodiment 1, prepare hydrotalcite precursor (CoAl-NO 3 LDHs).

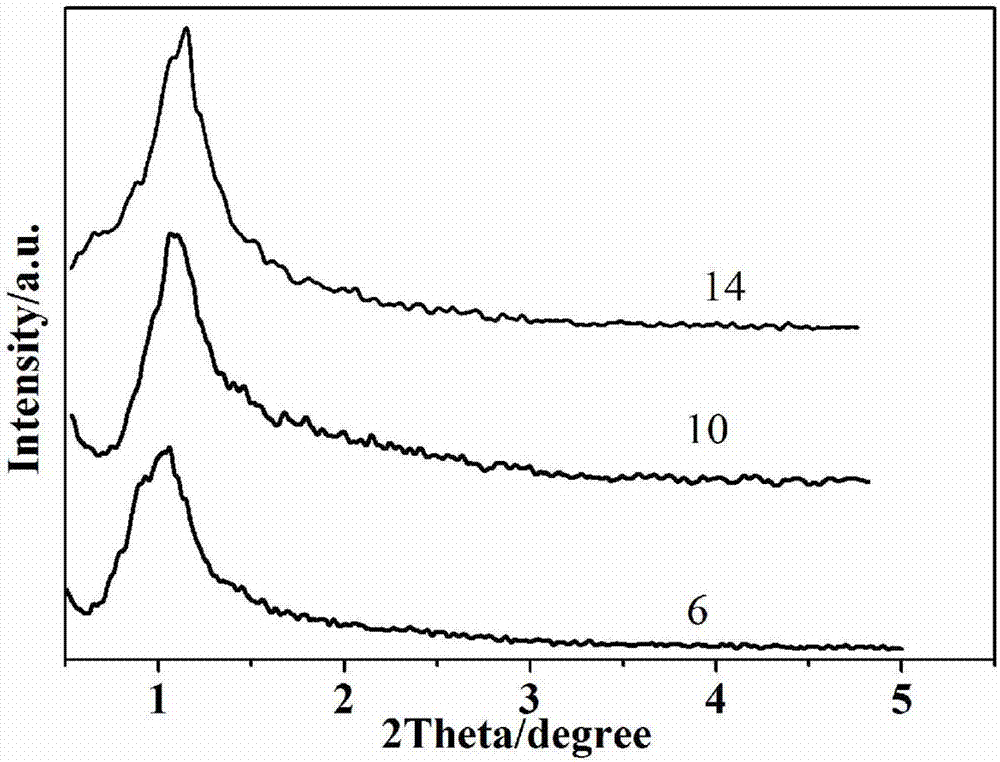

[0050] (2) Preparation of CoAl-NO intercalated with luminol monosodium salt (AMS) 3 LDHs: First weigh 0.51g CoAl-NO 3 LDHs and 0.152g of AMS were dissolved in 102ml of CO removal 2 water to obtain the mixed solution D, put the mixed solution D in a 150ml three-necked flask, stir and react for 50h under the protection of nitrogen, and the obtained product is depleted of CO 2 Water was centrifuged to obtain precipitate R3, which was then used to remove CO 2 The precipitate R3 was washed with water, and the upper layer was centrifuged to obtain an AMS-CoAl LDHs colloidal solution. The obtained precipitate R3 was dried in an oven at 70°C for 26 hours to obtain an AMS-CoAl LDHs sample.

[0051] (3) Prepare a CdTe QDs solution with a concentration of 1.0 mg / mL; prepare a PDDA solution with a concentration of 1 g / ml, and store them in volumetric flasks in the dark.

[0052] (4) Take a tin-doped indi...

Embodiment 3

[0056] (1) With embodiment 1, prepare hydrotalcite precursor CoAl-NO 3 LDHs.

[0057] (2) Preparation of CoAl-NO intercalated with luminol monosodium salt (AMS) 3 LDHs: First weigh 0.50g CoAl-NO 3 LDHs and 0.148g of AMS were dissolved in 101ml of CO removal 2 water to obtain a mixed solution D, put the mixed solution D in a 150ml three-necked flask, stir and react for 51h under nitrogen protection, and the obtained product is depleted of CO 2 Water was centrifuged to obtain precipitate R3, which was then used to remove CO 2 The precipitate R3 was washed with water, and the upper layer was centrifuged to obtain an AMS-CoAl LDHs colloidal solution. The obtained precipitate R3 was dried in an oven at 70°C for 24 hours to obtain an AMS-CoAl LDHs sample.

[0058] (3) Prepare a CdTe QDs solution with a concentration of 1.0 mg / ml; prepare a PDDA solution with a concentration of 1 g / ml, and store them in volumetric flasks in the dark.

[0059] (4) Take an ITO sheet with a size of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com