Nano fluorescence sensor as well as preparation method and application thereof

A nano-fluorescence and sensor technology, applied in the field of fluorescent sensing materials, can solve problems such as single property, photobleaching, solid-state quenching of fluorescent probe materials, etc., achieve good photostability, enhance detection limit, and avoid photobleaching Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] The preparation of organic fluorescent molecule DHBM comprises the following steps:

[0056] (1) Sodium bisulfite (0.97g, 9.3mmol) and 4-(diethylamino) salicylaldehyde (1.79g, 9.3mmol) were reacted in absolute ethanol (50mL) at room temperature for 12h;

[0057] (2) Dissolve 3,4-diaminobenzoic acid (1.41g, 9.3mmol) in 50mL DMF, then add it to the reaction mixture obtained in step (1), reflux at 80°C for 12h, cool the reaction bottle to room temperature, solvent in Evaporate under reduced pressure; Then add deionized water (100mL), a large amount of precipitate occurs;

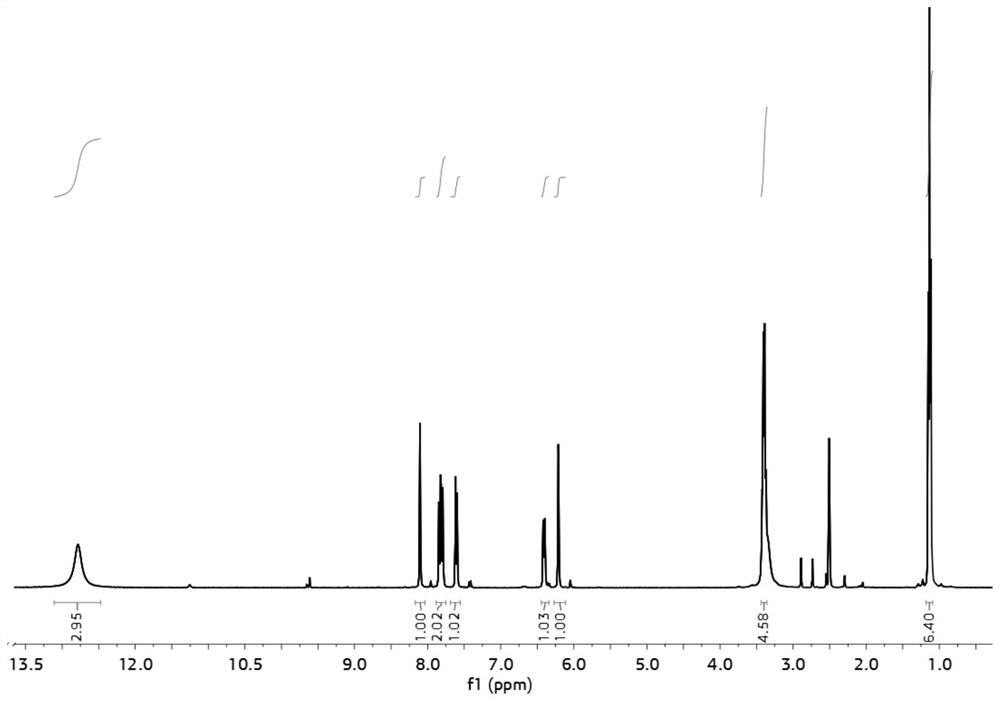

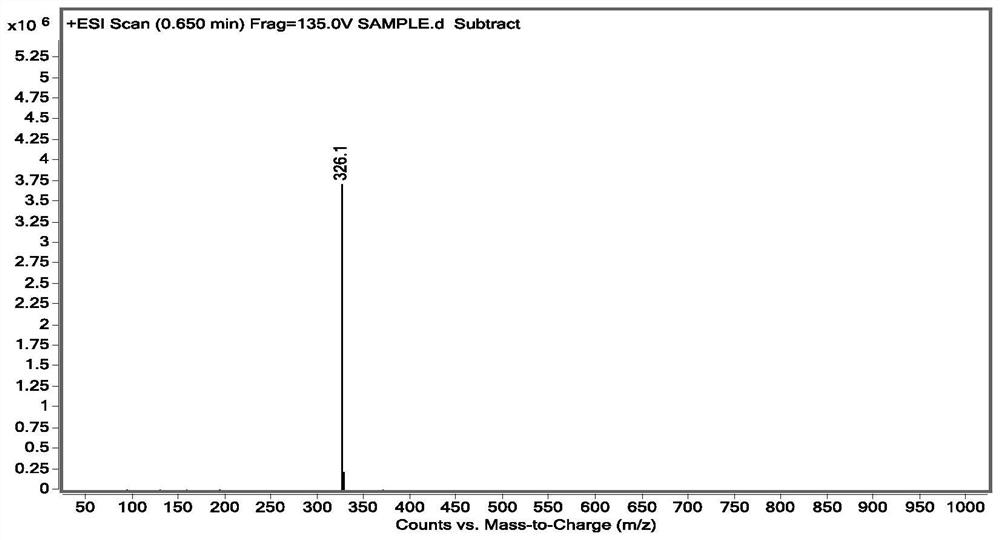

[0058] (3) The precipitate obtained in step (2) was collected by filtration, and dried in vacuum for 2 days to obtain the yellow product DHBM with a yield of 2.39 g, 75%. 1 H NMR (400MHz, DMSO-d6) δ (ppm) 12.77 (s, 3H, PhCOOH, PhOH, C-NH), 8.11 (s, 1H, PhH), 7.85 (s, 1H, PhH), 7.79 (d, 1H,PhH),7.61(d,1H,PhH),6.39(d,1H,PhH),6.21(s,1H,PhH),3.41(m,4H,CH 2 ),1.15(t,6H,CH 3 ).ESI+HR-MS calcd for DMBM[M+H]...

Embodiment 2

[0061] NH 2 -The preparation of MSN comprises the following steps:

[0062] (1) Dissolve CTAB (200mg) in 100mL of distilled water, add NaOH aqueous solution (0.7mL, 2M); after stirring the resulting mixed solution at 80°C for 30min, add 1mL of ethyl orthosilicate under vigorous stirring (800rpm) , stirred for 4h, cooled to room temperature and filtered to collect the precipitate;

[0063] (2) The precipitate obtained in step (1) was fully washed 3 times with deionized water and ethanol, and dried in vacuum at room temperature for 2 days; then the product was placed in a muffle furnace at 500°C for 5 hours to remove the template and obtain the product MSN;

[0064] (3) Put 200mg of MSN and 2mL of (3-aminopropyl)triethoxysilane into 10mL of toluene, stir at 30°C for 12h under nitrogen protection, and collect by centrifugation to obtain the product NH 2 -MSN, after which methanol washed 3 times and vacuum dried for 2 days.

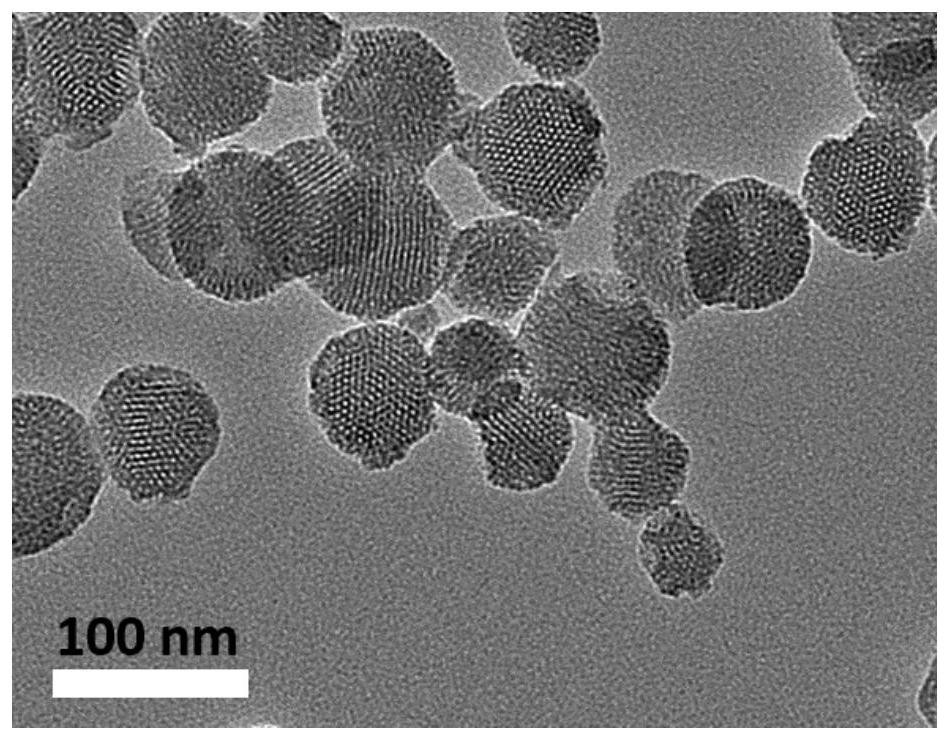

[0065] For the obtained product NH 2 -Observe the m...

Embodiment 3

[0067] The preparation of DHBM-MSN includes the following steps:

[0068] DHBM (0.02g, 0.09mmol), N-hydroxysuccinimide (0.01g, 0.09mmol) and 1-ethyl-(3-dimethylaminopropyl) carbodiimide hydrochloride (0.02g, 0.09mmol) was suspended in 5mL DMF, stirred at room temperature for 4h; then, 100mg of the NH obtained in Example 2 was added 2 -MSN, stirred at 30°C for 12h. The product was separated by centrifugation, washed three times with methanol, and vacuum-dried to obtain a product powder, which was designated as DHBM-MSN.

[0069] The porosity of the prepared DHBM-MSN was measured, and the result was 0.82cm 3 / g.

[0070] In the prepared DHBM-MSN, the proportion of DHBM on the surface and pores of mesoporous silica was detected, and the result was 55%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com