High-energy-storage self-supporting PEDOTs:PSS composite film and preparation method thereof

A composite film and self-supporting technology, which is applied in the field of composite material processing, can solve problems such as high-performance supercapacitors, dangerous solvents, multi-steps, and cumbersome procedures, and achieve good application prospects, high rate performance, and high charge and discharge stability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] High-energy storage flexible self-supporting PEDOTs:PSS / metal oxide composite membrane, made of the following components by weight: 20 parts of PEDOT:PSS (mass ratio 2:5) aqueous solution, 0.26 parts of ruthenium dioxide, dimethyl sulfoxide 600 parts of solvent.

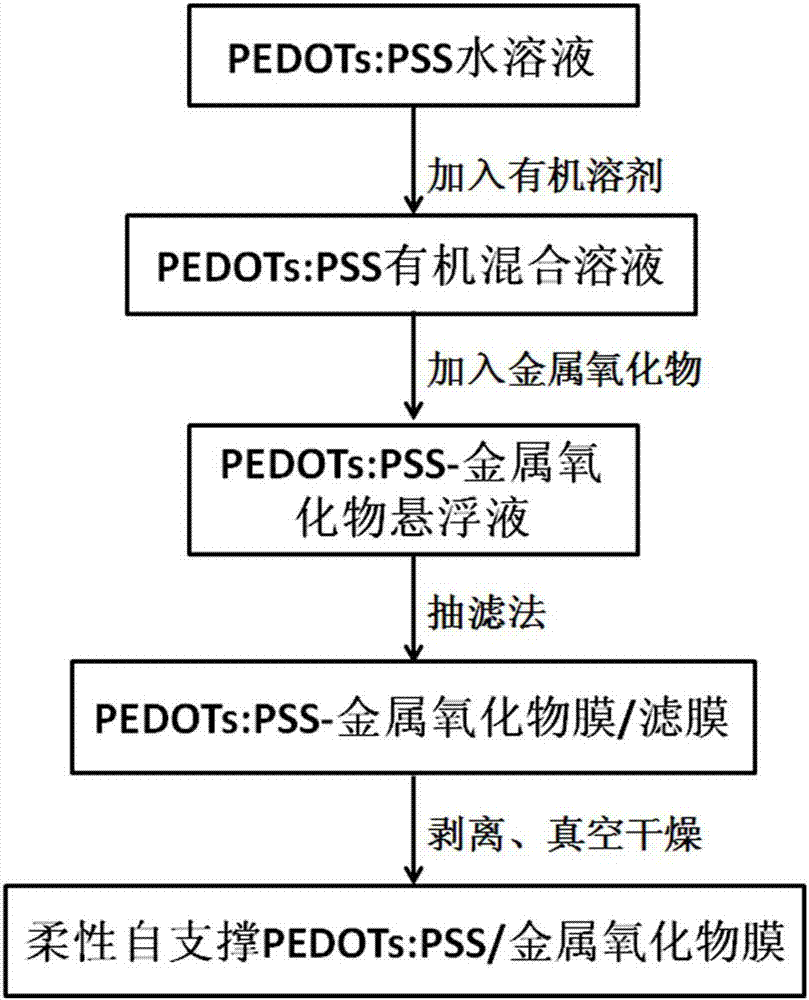

[0031] Preparation methods include:

[0032] Step 1: Stir and mix dimethyl sulfoxide and PEDOT:PSS aqueous solution at a weight ratio of 30:1, and obtain PEDOT:PSS organic mixed solution after ultrasonic degassing for 1 min;

[0033] Step 2: Add 0.26 parts of ruthenium dioxide to the PEDOT:PSS organic mixed solution prepared in step 1, and obtain a uniform suspension after ultrasonication;

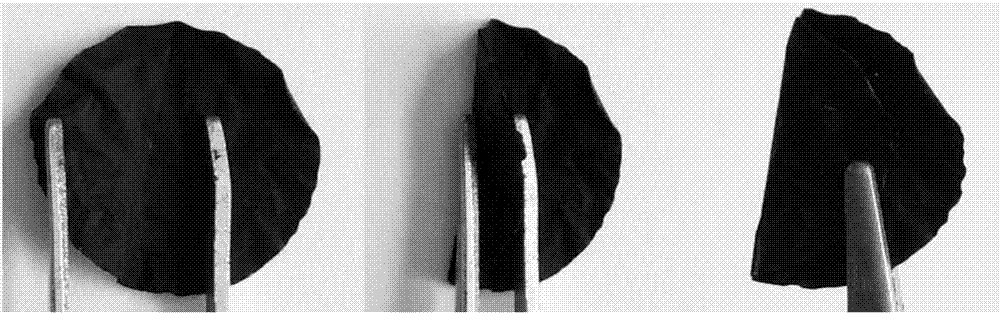

[0034] Step 3: Vacuum filter the suspension prepared in step 2. After the suction filtration, put the filter membrane in water to separate the PEDOT:PSS composite membrane and the PVDF filter membrane, and dry it in vacuum at 100°C for 24 hours to obtain flexible self-supporting PEDOT: PSS composite film.

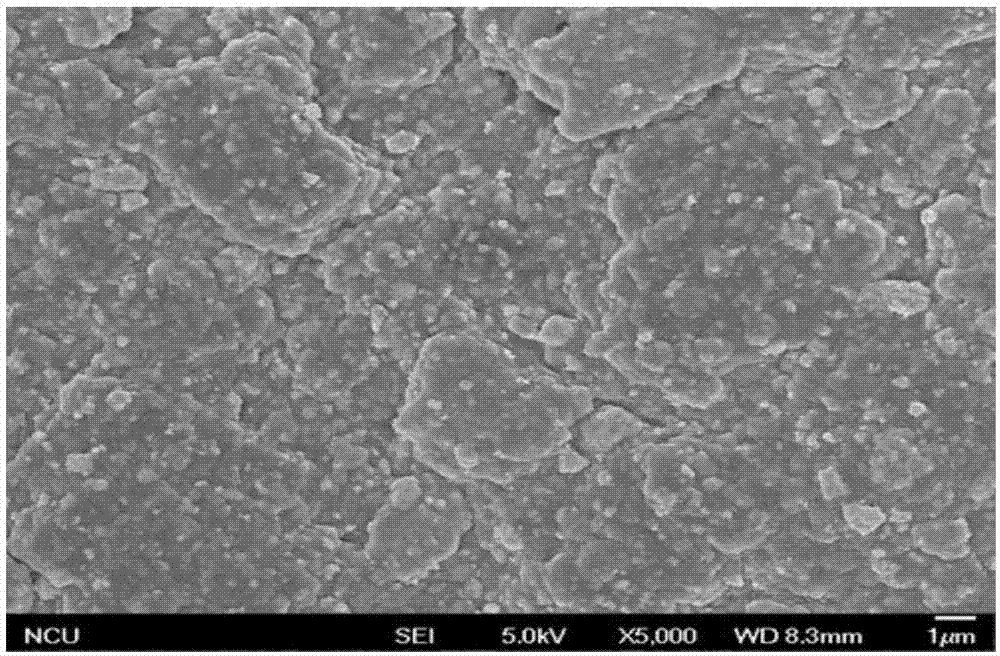

[0035] The a...

Embodiment 2

[0037] High-energy storage flexible self-supporting PEDOTs:PSS / metal oxide composite film, made of the following components by weight: 18 parts of aqueous solution of methylol PEDOT:PSS (mass ratio 1:3), 0.2 parts of tungsten trioxide, N - 600 parts of methylpyrrolidone solvent.

[0038] Preparation methods include:

[0039] Step 1: Stir and mix the N-methylpyrrolidone solvent and the hydroxymethyl PEDOT:PSS aqueous solution at a weight ratio of 100:3, and after ultrasonic degassing for 1 min, obtain a hydroxymethyl PEDOT:PSS organic mixed solution;

[0040] Step 2: Add 0.2 parts of tungsten trioxide to the hydroxymethyl PEDOT:PSS organic mixed solution prepared in step 1, and obtain a uniform suspension after ultrasonication;

[0041] Step 3: Vacuum filter the suspension prepared in step 2. After the suction filtration, put the filter membrane in water to separate the hydroxymethyl PEDOT:PSS composite membrane from the PVDF filter membrane, and dry it in vacuum at 80°C for 4...

Embodiment 3

[0044] High-energy storage flexible self-supporting PEDOTs:PSS / metal oxide composite film, made of the following components by weight: 20 parts of chloromethyl PEDOT:PSS (mass ratio 1:5) aqueous solution, 0.1 part of molybdenum trioxide, tricobalt tetroxide 0.15 parts, 500 parts of isopropanol solvent.

[0045] Preparation methods include:

[0046] Step 1: Stir and mix isopropanol solvent and chloromethyl PEDOT:PSS aqueous solution at a weight ratio of 25:1, and after ultrasonic degassing for 1 min, obtain chloromethyl PEDOT:PSS organic mixed solution;

[0047] Step 2: Add 0.1 part of molybdenum trioxide and 0.15 part of tricobalt tetroxide to the chloromethyl PEDOT:PSS organic mixed solution prepared in step 1, and obtain a uniform suspension after ultrasonication;

[0048] Step 3: Vacuum filter the suspension prepared in step 2. After the suction filtration, put the filter membrane in water to separate the chloromethyl PEDOT:PSS composite membrane from the PVDF filter membr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com