A surface with pneumatic control of wettability, its preparation method and its application in droplet collection

A wettable, aerodynamic technology that is used in processes for producing decorative surface effects, microstructure devices composed of deformable elements, electrical components, etc. It can achieve the effect of large controllability and intelligence, large adjustment range of surface structure, and significant adjustment of surface wettability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

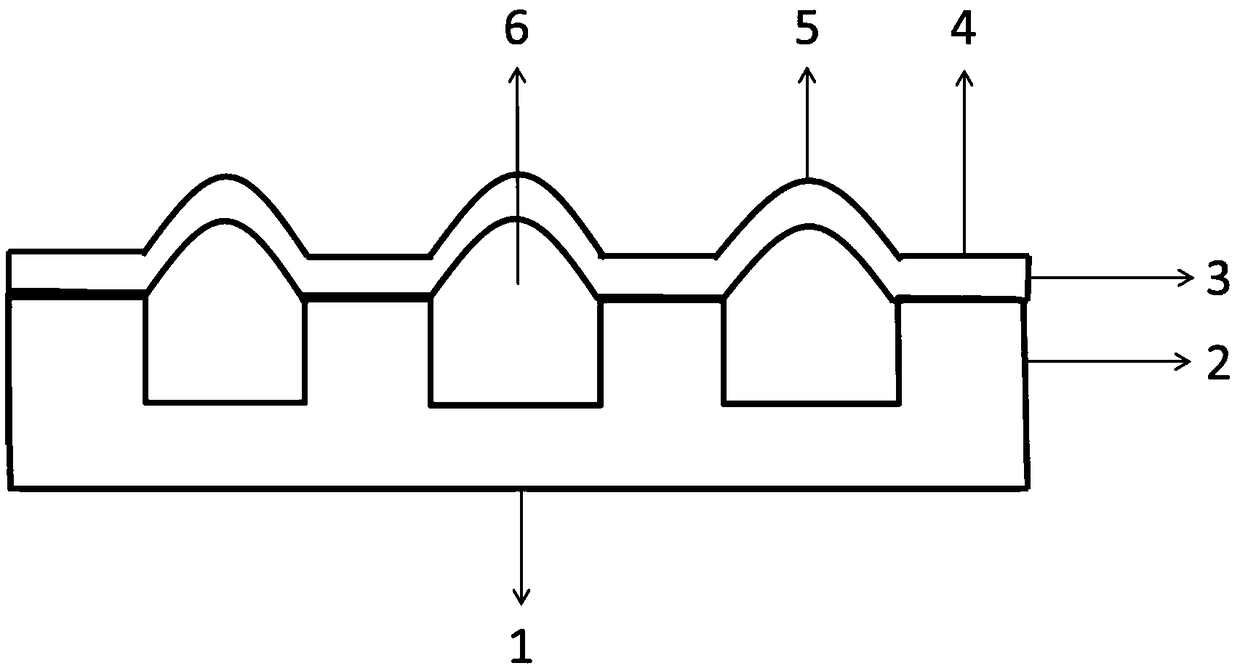

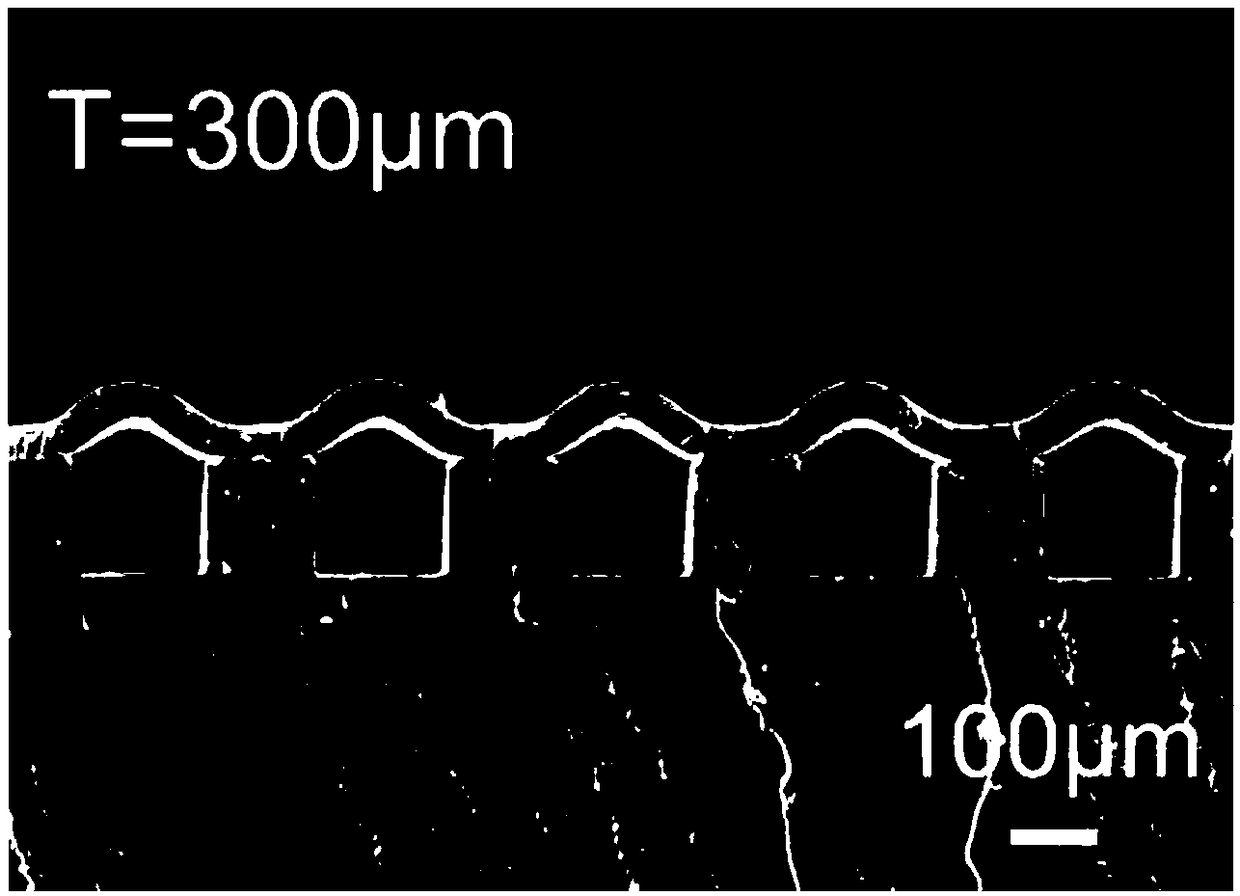

[0046] Aerodynamically responsive structures with raised air pockets were fabricated using a "stretch-bonding" process.

[0047] A method for preparing an aerodynamic response structure with raised airbags by using "stretch bonding", the specific steps are as follows:

[0048] (1) Preparation of gas path structure layer: including hard template photolithography and soft etching of gas path structure;

[0049] The specific steps are as follows: firstly, spin-coat SU8 photoresist flat film on the glass substrate, the rotation speed is 2000r / min, the time is 60s, and the film thickness is 100μm; then, carry out ultraviolet exposure for 7min, develop for 10min, and form a Then, inject the PDMS prepolymer mixture into the hard template to form a liquid layer with a thickness of 5mm on the surface of the hard template, and heat it at 65°C for 0.5h to cure it; finally, the PDMS cured layer Separate from the hard template to obtain the positive structure corresponding to the hard tem...

Embodiment 2

[0055] Enhancing aerodynamic regulation of surface wettability by surface selective modification.

[0056] Studies have shown that the superhydrophobicity of the material surface can be greatly improved by modifying the surface nanostructure. At the same time, the aerodynamic response structure of the present invention can be convex or concave with the inflation and deflation of the raised micro-airbag, so that the actual contact surface between the surface and the droplet is between the top of the micro-airbag and the bonding area between the micro-airbag Switch back and forth. Accordingly, the surface of the aerodynamic responsive structure can be selectively modified, that is, the nanoparticle deposition is only performed on the surface of the bonding area (that is, the groove area between the micro-airbags in the natural state), while the top surface of the micro-airbag remains intact. In this way, a micro-nano multi-level structure composed of aerodynamic micro-structure...

Embodiment 3

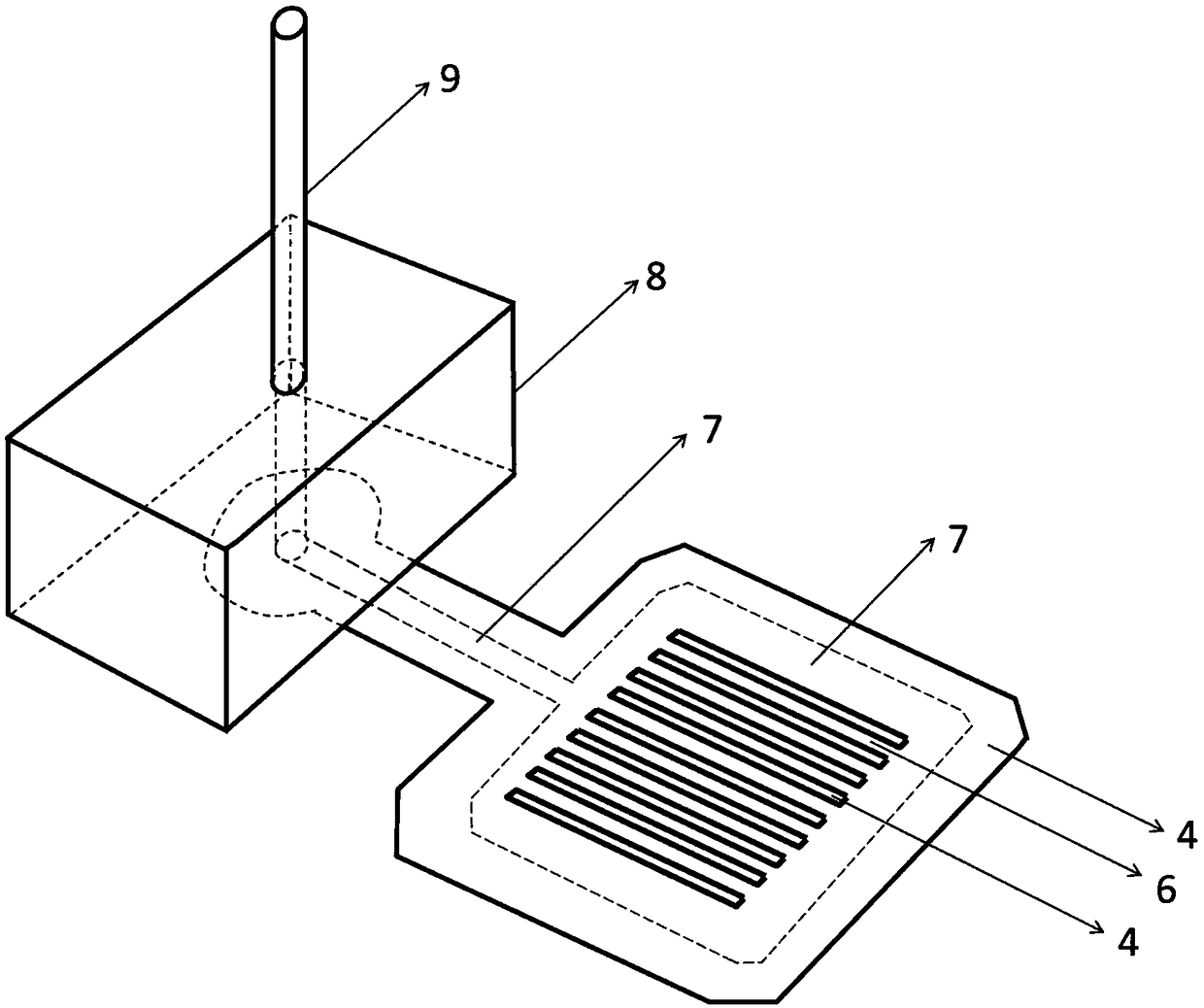

[0063] Pneumatically modulated wettability surfaces are applied to droplet collection.

[0064] The present invention obtains a surface that can directly switch the wetting state by inflation and deflation by combining "stretching bonding" and surface selective modification. When the gas is inflated, the surface wetting state is a transition state, and the droplet is fixed on the surface of the aerodynamic response structure due to the large atomic force on the contact surface; while the surface state changes to the Cassie-Baxter state when the gas is deflated, and the atomic force on the droplet is greatly reduced. , causing it to be released from the surface and roll quickly across the surface. In this way, the intelligent collection of liquid droplets on the surface of the present invention can be realized by using air inflation and deflation.

[0065] Pneumatic control of wettable surface is applied to droplet collection, the specific steps are:

[0066] (1) The aerodyna...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com