Punching-resistant LED-UV metal printing offset ink

A technology of offset printing ink and stamping resistance, applied in the field of offset printing ink for iron printing, can solve the problems of difficult drying, high heat generation, poor stamping resistance of ink film, etc., achieve good adhesion and flexibility, improve bending elongation, and resist Impact strength improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A stamping resistant LED-UV iron printing offset printing ink, in parts by mass, its composition is: 17 parts of magenta 6B (made by DIC), 54.7 parts of polyester acrylate CN2203 (made by Sartomer), 4 parts of photoinitiated TPO, 3 parts of photoinitiator 1173, 3 parts of photoinitiator BDK, 2 parts of photoinitiator 907, 11 parts of active diluent DTMPTA, 0.3 parts of graphene SE1430 (manufactured by Changzhou Sixth Carbon Element Technology Co., Ltd.), 2 Parts of auxiliary agent three (N-nitroso-N-phenylhydroxylamine) aluminum salt, 3 parts of nano calcium carbonate.

[0021] The above-mentioned parts by weight of each raw material are mixed in a batching kettle, and stirred at 1000rpm / min for 50 minutes to obtain a slurry. After the slurry is fully milled by Buhler three-roller until the slurry fineness is less than 5μm, the LED-UV for offset printing can be obtained. Printing ink.

Embodiment 2

[0027] A stamping resistant LED-UV iron printing offset printing ink, in parts by mass, its composition is: 13 parts PY.13 (made by Clariant), 59.7 parts of polyester acrylate CN2203 (made by Sartomer), 4 parts Photoinitiator TPO, 3 parts of photoinitiator 1173, 4 parts of photoinitiator BDK, 2 parts of photoinitiator 369, 9 parts of active diluent DPHA, 0.3 parts of graphene TNGNPs (manufactured by Chengdu Organic Chemistry Co., Ltd., Chinese Academy of Sciences), 2 Parts of auxiliary agent three (N-nitroso-N-phenylhydroxylamine) aluminum salt, 3 parts of nano calcium carbonate.

[0028] The above-mentioned parts by weight of the raw materials are mixed in the batching kettle, and stirred at 1000rpm / min for 50 minutes to obtain the slurry. After the slurry is fully milled by Buhler three-roller until the slurry fineness is less than 5μm, the LED-UV for offset printing can be obtained. Printing ink.

Embodiment 3

[0030] A stamping resistant LED-UV iron printing offset ink, in parts by mass, its composition is: 16 parts of PY.13 (made by Clariant), 52.6 parts of epoxy acrylate, 4 parts of photoinitiator BAPO, 3.5 parts of light Initiator 184, 4 parts of photoinitiator BDK, 2.5 parts of photoinitiator 369, 11 parts of reactive diluent DPPA, 0.4 parts of graphene TNGNPs (manufactured by Chengdu Organic Chemistry Co., Ltd., Chinese Academy of Sciences), 3 parts of auxiliary agent three (N-Asia) Nitro-N-phenylhydroxylamine) aluminum salt, 3 parts of nano calcium carbonate.

[0031] The above-mentioned parts by weight of the raw materials are mixed in the batching kettle, and stirred at 1000rpm / min for 50 minutes to obtain the slurry. After the slurry is fully milled by Buhler three-roller until the slurry fineness is less than 5μm, the LED-UV for offset printing Printing ink.

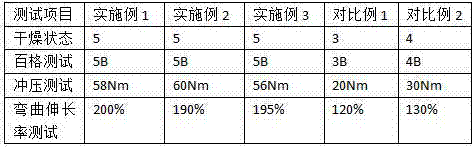

[0032] The tests performed on the inks prepared in the above embodiments are as follows:

[0033] Using a simple color ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com