Preparation method of anode material of lithium battery

A positive electrode material and lithium battery technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as poor low temperature performance, reduced battery discharge capacity, and decreased battery charge and discharge performance, and achieve good conductivity and flexibility. Effect of increasing charge and discharge capacity and improving charge and discharge performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

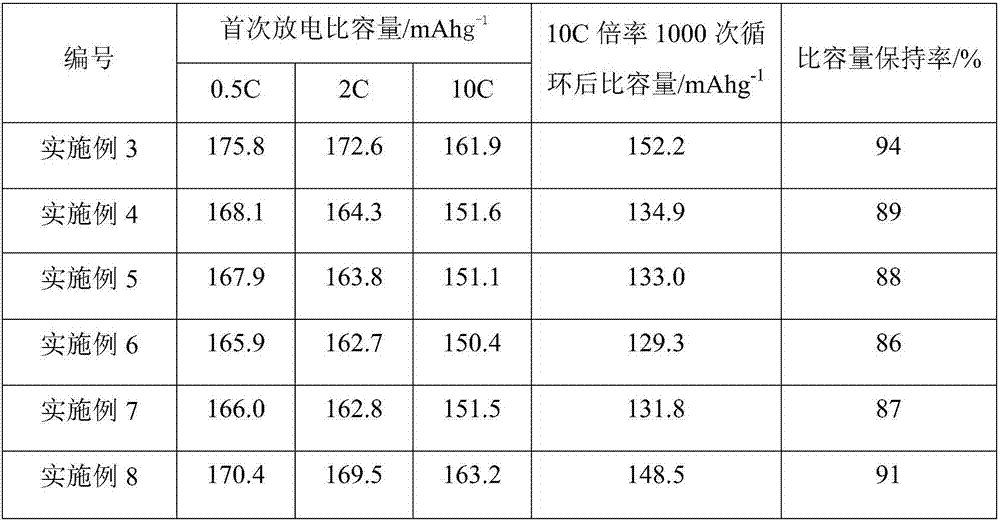

Examples

Embodiment 1

[0027] A preparation method for a lithium battery cathode material, comprising the following steps:

[0028] Step A, divide the positive electrode active material into three equal parts, divide the conductive agent into three equal parts, divide the binder into four parts by weight ratio 1:1:1:1.2, and divide the dispersant into four parts by weight ratio 1:1:1:2 is divided into four parts, pour the first part of the binder into the mixer with solvent, and add the first equal part of the conductive agent and the first equal part of the solvent to the mixer while stirring. Positive electrode active material, after the first equal portion of conductive agent and the first equal portion of positive active material are added, add the first portion of dispersant to the mixer, stir at high speed for 1 hour and then vacuumize, when the vacuum degree in the mixer reaches 0.01 MPa, continue pumping for 3 minutes, and stir at a medium speed for 1.5 hours under vacuum. After the stirring...

Embodiment 2

[0038] A preparation method for a lithium battery cathode material, comprising the following steps:

[0039] Step A, divide the positive electrode active material into three equal parts, divide the conductive agent into three equal parts, divide the binder into four parts by weight ratio 1:1:1:1.2, and divide the dispersant into four parts by weight ratio 1:1:1:2 is divided into four parts, pour the first part of the binder into the mixer with solvent, and add the first equal part of the conductive agent and the first equal part of the solvent to the mixer while stirring. Positive electrode active material, after the first equal portion of conductive agent and the first equal portion of positive active material are added, add the first portion of dispersant to the mixer, stir at high speed for 2 hours and then vacuumize, when the vacuum degree in the mixer reaches 0.01 MPa, continue pumping for 3 minutes, and stir at a medium speed for 2.5 hours under vacuum. After the stirrin...

Embodiment 3

[0049] A preparation method for a lithium battery cathode material, comprising the following steps:

[0050] Step A, divide the positive electrode active material into three equal parts, divide the conductive agent into three equal parts, divide the binder into four parts by weight ratio 1:1:1:1.2, and divide the dispersant into four parts by weight ratio 1:1:1:2 is divided into four parts, pour the first part of the binder into the mixer with solvent, and add the first equal part of the conductive agent and the first equal part of the solvent to the mixer while stirring. Positive electrode active material, after the first equal portion of conductive agent and the first equal portion of positive active material are added, add the first portion of dispersant to the mixer, stir at high speed for 1.5h and then vacuumize, when the vacuum in the mixer reaches When the pressure is 0.01MPa, continue pumping for 3 minutes, and stir at a medium speed for 2 hours in a vacuum state. Afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com