Preparation method of corn kernel fermented feed

A technology of fermented feed and production method, which is applied in the direction of animal feed, animal feed, application, etc., can solve the problems of strict production conditions, loss of nutrients, easy to corrupt, etc., and achieves high aerobic stability, easy operation and fermentation. Conditions are not demanding for effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

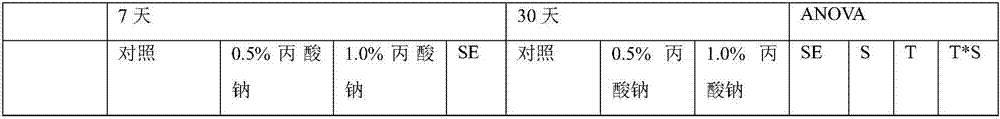

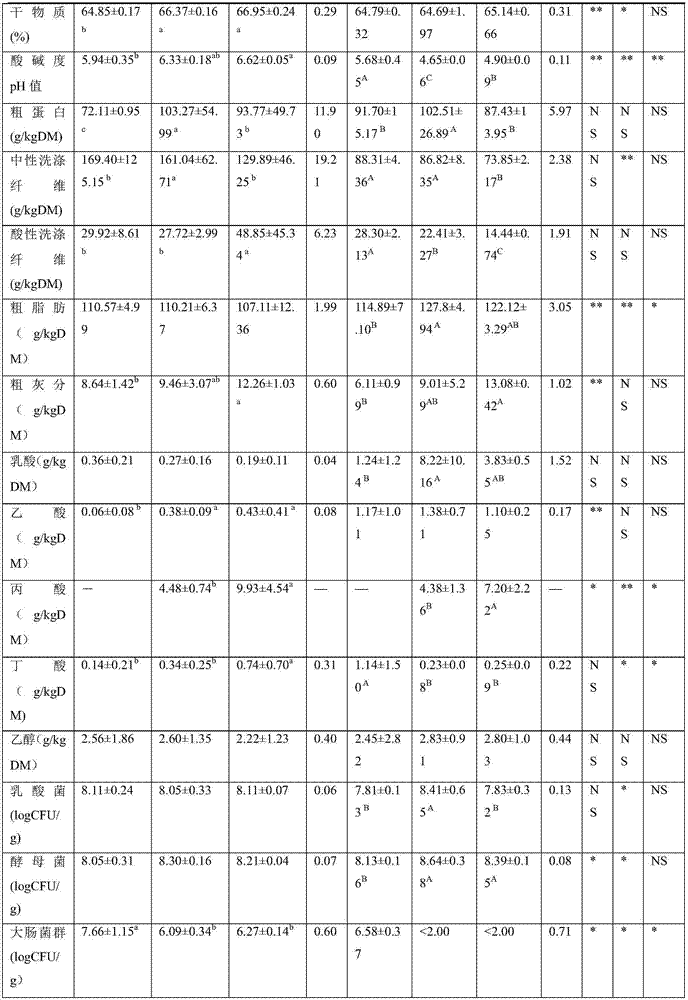

Examples

specific Embodiment approach 1

[0017] Specific embodiment one: the preparation method of corn grain fermented feed of the present embodiment carries out according to the following steps:

[0018] 1. Threshing corn seeds with a water content of 25%-30% to obtain corn seeds;

[0019] Two, take by weighing sodium propionate (food grade, purity 99%) according to the ratio of 0.5%-1% of corn grain weight, take by weighing water according to the ratio of 5%-10% of corn grain weight, sodium propionate is dissolved in water, obtains Sodium propionate aqueous solution;

[0020] 3. Spray the sodium propionate aqueous solution evenly (spraying method) on the corn kernels, stir evenly, then compact and seal, and cover the surface of the compacted corn kernels with 10cm-20cm thick soil or heavy objects;

[0021] 4. Store at room temperature for 1 month to obtain corn grain fermented feed.

specific Embodiment approach 2

[0022] Embodiment 2: This embodiment is different from Embodiment 1 in that in step 1, the corn with a moisture content of 26% is threshed to obtain corn kernels. Others are the same as the first embodiment.

specific Embodiment approach 3

[0023] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that in Step 1, corn with a water content of 27% is threshed to obtain corn kernels. Others are the same as the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com