Method for in-situ preparation of Au/graphene nanocomposite through supercritical CO2

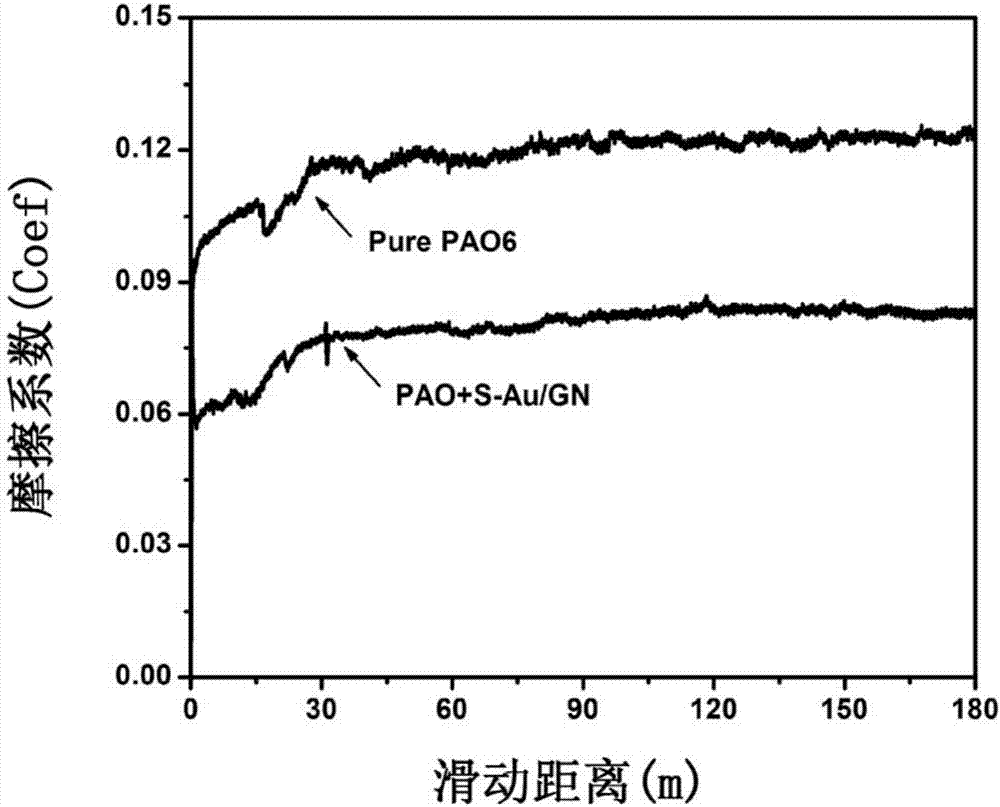

A nano-composite material and in-situ preparation technology, which is applied in the field of supercritical CO2 in-situ preparation of Au/graphene nano-composite materials, can solve the problem of large size difference of nano-metal particles, uneven distribution of nanoparticles, low metal content, etc. problems, to achieve the effect of easy industrial implementation, high comprehensive macro performance and good batch performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Supercritical CO 2 In situ preparation of Au / graphene nanocomposites, the steps are as follows:

[0040] (1) Weigh 100mg graphene oxide, 100mg gold chlorate, 5mg sodium lauryl sulfate, add to 50ml ethanol, add 2ml aqueous solution containing 120mg glucose, ultrasonic treatment for 5min;

[0041] (2) Put the uniform dispersion liquid and magnetic stirrer into the reaction kettle, and introduce CO 2 Exhaust the air, pressurize and heat to 8Mpa and 150°C respectively, and react for 2h at a stirring speed of 400r / min;

[0042] (3) Release the pressure and cool at a speed of 0.2Mpa / min, wash the product repeatedly with absolute ethanol and deionized water 4 times, and dry it in vacuum. The obtained powder is the Au / graphene nanocomposite material.

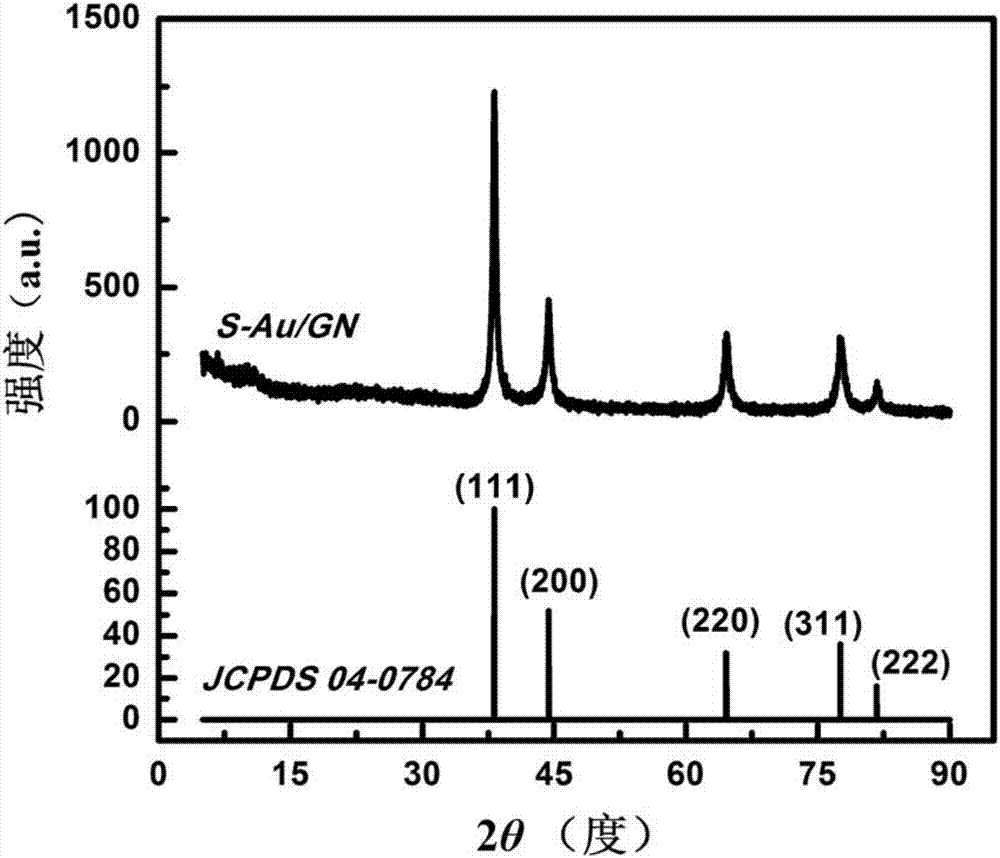

[0043] figure 1 For the XRD diffraction pattern of the prepared Au / graphene nanocomposite material, it can be seen from the standard card that no other impurities exist.

Embodiment 2

[0045] Supercritical CO 2 In situ preparation of Au / graphene nanocomposites, the steps are as follows:

[0046] (1) Weigh 100mg of graphene oxide, 200mg of gold chlorate, 10mg of sodium dodecylbenzenesulfonate, add to 50ml of ethanol, add 2ml of aqueous solution containing 240mg of glucose at the same time, sonicate for 10min;

[0047] (2) Put the uniform dispersion liquid and magnetic stirrer into the reaction kettle, and introduce CO 2 Exhaust the air, pressurize and heat to 12Mpa and 120°C respectively, and react for 2h at a stirring speed of 600r / min;

[0048] (3) Release the pressure and cool at a speed of 0.3Mpa / min, wash the product repeatedly with absolute ethanol and deionized water 4 times, and dry it in vacuum. The obtained powder is the Au / graphene nanocomposite material.

[0049] The XRD diffraction pattern of the prepared Au / graphene nanocomposite is shown in figure 1 , but the intensity of the diffraction peak corresponding to the gold nanocrystals becomes la...

Embodiment 3

[0051] Supercritical CO 2In situ preparation of Au / graphene nanocomposites, the steps are as follows:

[0052] (1) Weigh 100mg graphene oxide, 200mg gold chlorate, 10mg sodium lauryl sulfate, add to 50ml ethanol, add 2ml aqueous solution containing 360mg glucose at the same time, sonicate for 10min;

[0053] (2) Put the uniform dispersion liquid and magnetic stirrer into the reaction kettle, and introduce CO 2 Exhaust the air, pressurize and heat to 12Mpa and 120°C respectively, and react at a stirring speed of 450r / min for 2h;

[0054] (3) Release the pressure and cool at a speed of 0.3Mpa / min, wash the product repeatedly with absolute ethanol and deionized water 4 times, and dry it in vacuum. The obtained powder is the Au / graphene nanocomposite material.

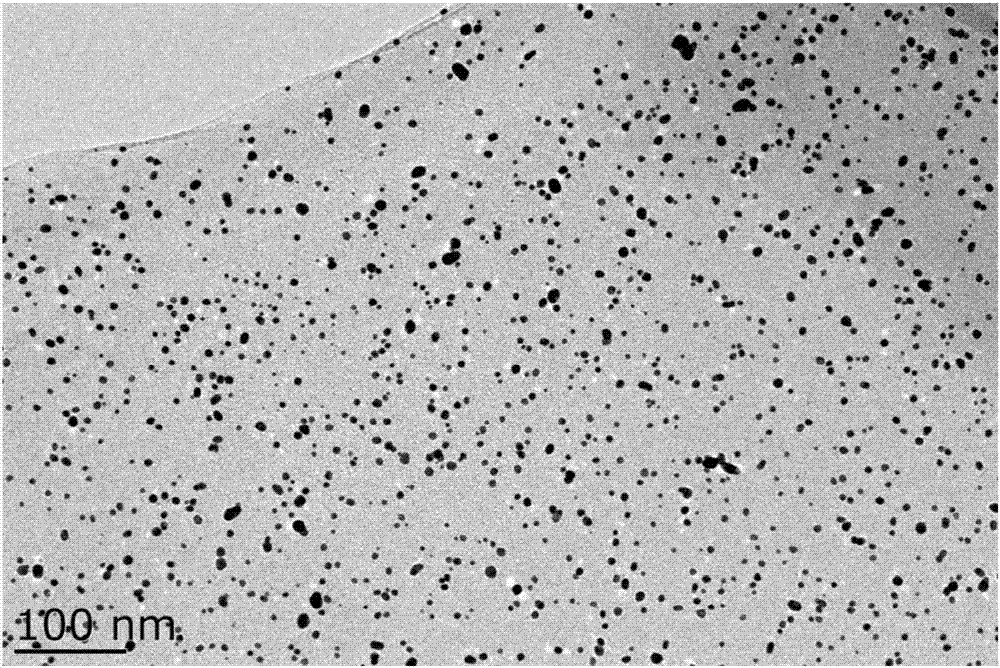

[0055] figure 2 The TEM image of the prepared Au / graphene nanocomposite material shows that the nano-gold crystals are granular, with a particle size of 5-10 nm, and are evenly distributed on the graphite wrinkled laye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com