Anaerobic reactor

An anaerobic reactor and reactor technology, applied in the field of anaerobic reactors, can solve the problems of unfavorable industrial production efficiency and continuous stability, slow growth of microorganisms, low reactor load, etc., so as to reduce the concentration of wastewater to be treated and improve the biological The effect of quantity and efficient treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

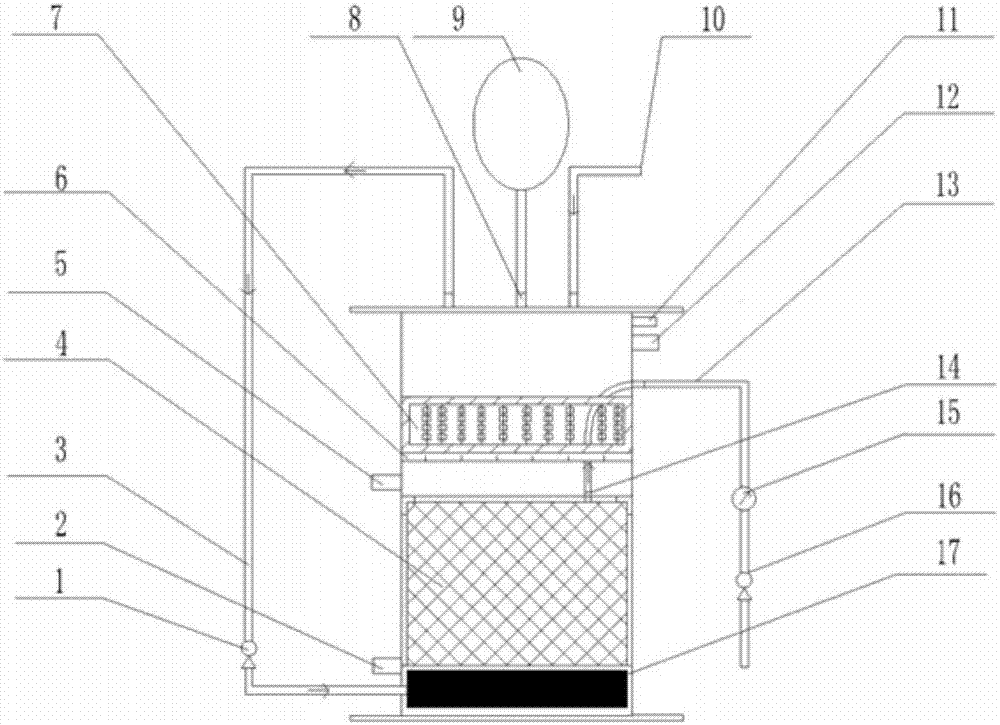

[0063] The anaerobic reactor of this embodiment has a rectangular parallelepiped structure with a total internal volume of 14L and an effective volume of 9L.

[0064] The internal temperature of the reactor is maintained at 35-37° C., and hot water is used for heat preservation. The hot water enters from the water inlet 2 of the water bath and is discharged from the water outlet 12 of the water bath.

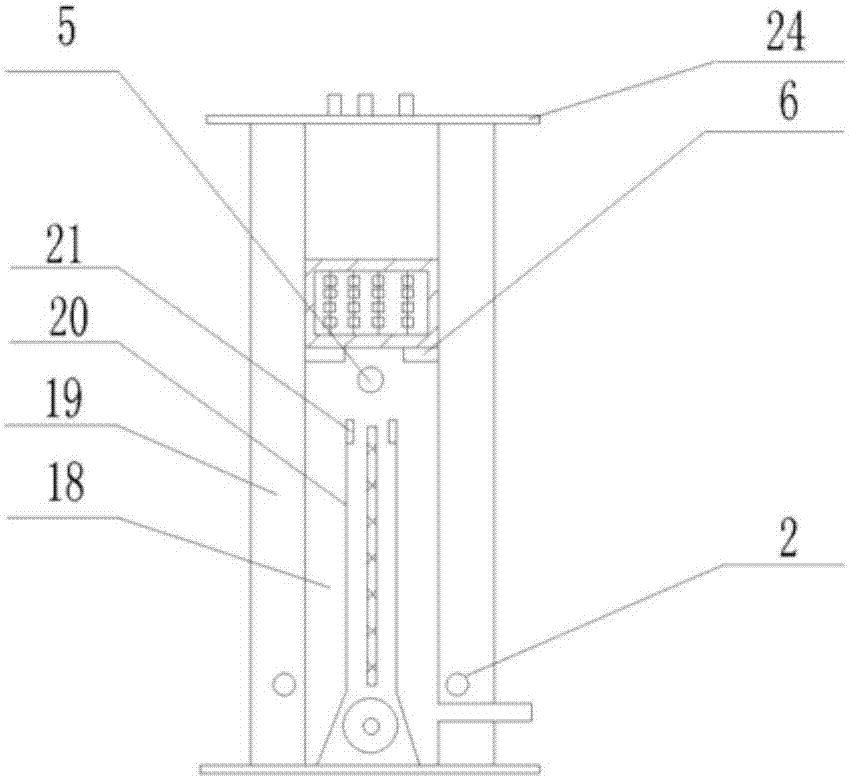

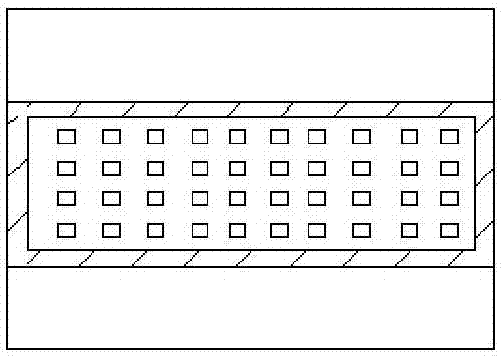

[0065] The filler 23 is a cubic block sponge of 1.5×1.5 cm, and there are 160 fillers 23 in total, and the fixed filler bed 7 is located 8 cm above the flat membrane 4 . The liquid after dehydration by the cow farm screw extruder is used as the waste water to be treated, the COD concentration is 25-30g / L, and the total solid concentration is about 30g / L.

[0066] The filtration flux of the flat membrane 4 is 5-6L / h, and the transmembrane pressure difference is -4.5 to -5.8kPa.

[0067] The waste water enters the reactor through the feed port 10, and the amount of waste water ad...

Embodiment 2

[0075] The anaerobic reactor of this embodiment has a rectangular parallelepiped structure with a total internal volume of 14L and an effective volume of 9L.

[0076] The internal temperature of the reactor is maintained at 37-40° C., and hot water is used for heat preservation. The hot water enters from the water inlet 2 of the water bath and is discharged from the water outlet 12 of the water bath.

[0077] The packing 23 is a spherical carrier of 2 cm polypropylene material, and the fixed packing bed 7 is located 15 cm above the flat membrane 4 . The pig farm wastewater is used as the treatment object, the COD concentration is 10-20g / L, and the total solid concentration is about 20g / L.

[0078] The filtration flux of the membrane is 5-6L / h, and the pressure difference across the membrane is -4.0-5.0kPa.

[0079] Pig farm wastewater enters the reactor through the feed port 10, and the amount of wastewater added is 1.8 L, which is mixed with the inoculated sludge in the reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com