Method and device for biologically producing methane and synchronously carrying out desulfurization

A biological methane production technology, applied in the direction of biochemical cleaning equipment, biochemical equipment and methods, enzymology/microbiology equipment, etc., can solve the problems of low energy consumption, reduce fermentation efficiency, etc., and improve production capacity and capacity enhanced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

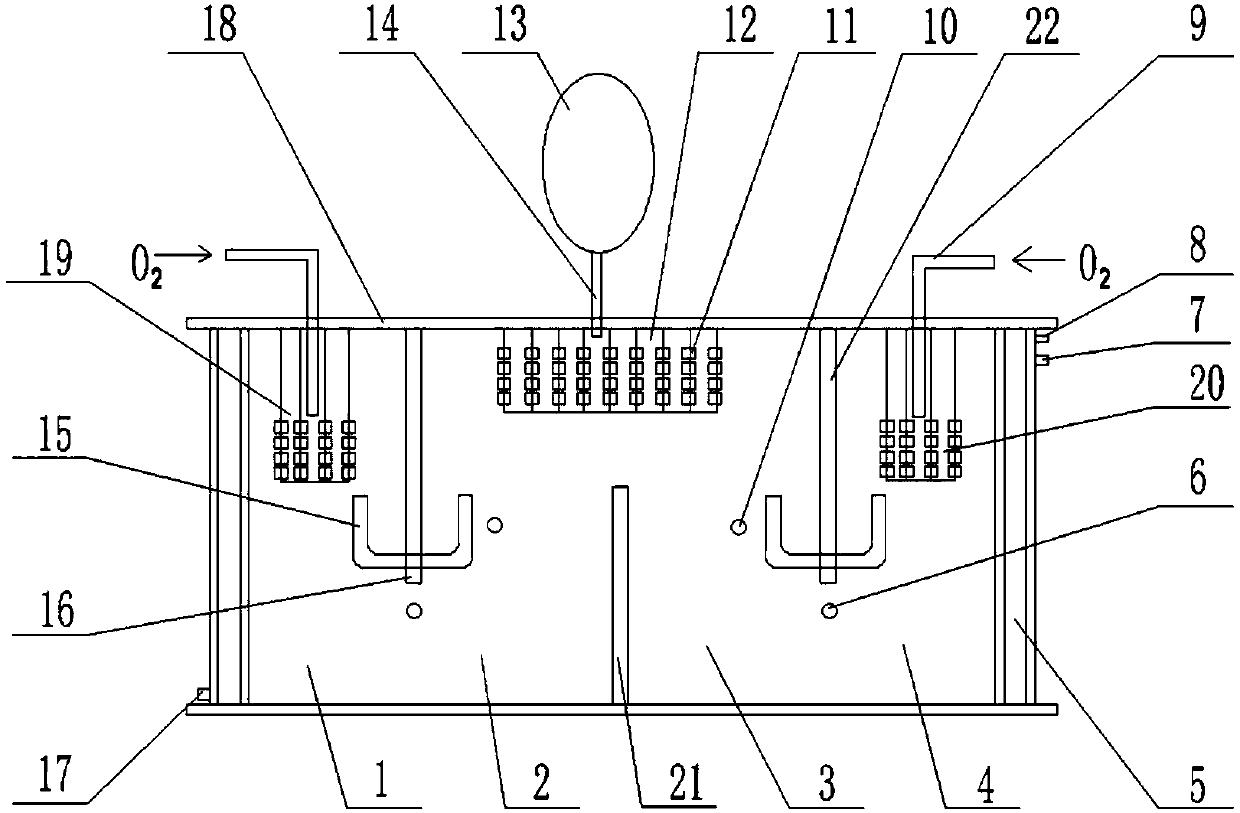

Embodiment 1

[0083] Anaerobic digestion of pig manure wastewater:

[0084] The solid concentration in the pig manure wastewater to be treated is 5-15g / L, and the volume to be treated is 20L.

[0085] a) Pass water into the interlayer 5 of the water bath. Pass the water of set temperature through the water bath water inlet 17, and fill the water bath interlayer 5. Wherein, the set temperature range of water is 33-37°C.

[0086] b) Cover the reactor cover 18, and start to feed the pig manure waste water to be treated through the feed port 6. When the liquid level of the pig manure waste water to be treated has not passed the top of the filler 11 in the first packed bed 19 and the third packed bed 20, stop feeding and close the feeding port 6. At this time, the intake pipe 9 is in a closed state, and the oxygen supply device is in a closed state.

[0087] The waste water level height of four compartments in the reactor is the same, at this moment, in the first compartment 1 and the fourth...

Embodiment 2

[0095] Anaerobic digestion of cow dung wastewater

[0096] The solid concentration in cow dung wastewater is 5-20g / L, and the volume to be treated is 30L.

[0097] a) Pass water into the interlayer 5 of the water bath. Pass the water of set temperature through the water bath water inlet 17, and fill the water bath interlayer 5. Wherein, the set temperature range of water is 33-37°C.

[0098] b) cover the reactor cover 18, and start to feed the cow dung waste water to be treated from the feed port 6. After the cow dung wastewater liquid level to be treated has not crossed the filler 11 tops in the first packed bed 19 and the third packed bed 20, stop feeding and close the feeding port 6. At this time, the intake pipe 9 is in a closed state, and the oxygen supply device is in a closed state.

[0099] The waste water level height of four compartments in the reactor is the same, at this moment, in the first compartment 1 and the fourth compartment 4, the packing 11 is complete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com