Anilofos, cyhalofop-butyl and metamifop-containing herbicide composition

A herbicidal composition, the technology of oxazolam, is applied in the directions of herbicides, algaecides, biocides, biocides, etc., to achieve the effects of wide herbicidal spectrum, short residual time, and safety of subsequent crops

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

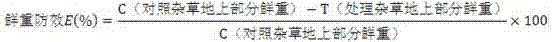

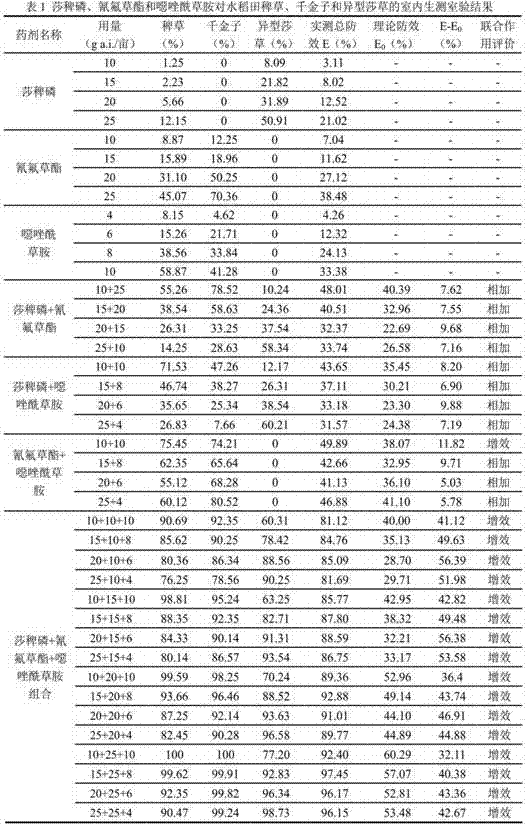

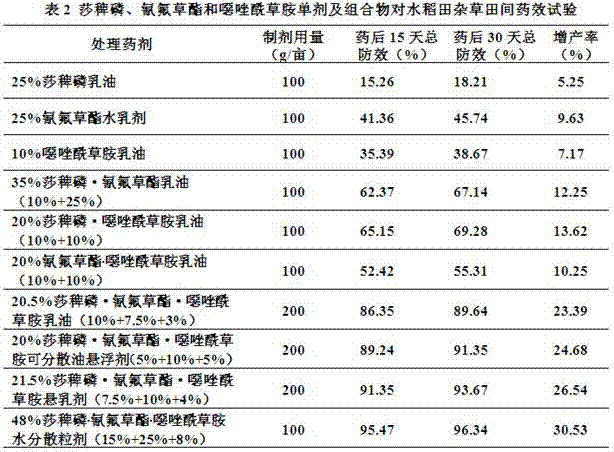

Method used

Image

Examples

Embodiment 1

[0015] Embodiment 1: when composition of the present invention is emulsifiable concentrate, each component content is:

[0016] Saponin 10%

[0017] Cyhalofop-methyl 7.5%

[0018] Methamphetamide 3%

[0019] Fatty alcohol polyoxyethylene ether 10%

[0020] Alkylphenol formaldehyde resin polyoxyethylene ether 6%

[0021] Ethylene glycol 5%

[0022] Xylene 10%

[0023] Ethyl acetate 5%

[0024] Deionized water make up to 100%

[0025] The specific processing steps of the emulsifiable concentrate of the composition are as follows: after mixing and dissolving according to the above-mentioned formula in proportion, it is mixed into a uniform and transparent phase by high-speed shearing, and the 20.5% sabaphos-cyhalofop-oxazole described in the present invention is obtained Amylamide EC.

Embodiment 2

[0026] Embodiment 2: when composition of the present invention is dispersible oil suspension concentrate, each component content is:

[0027] Saponin 5%

[0028] Cyhalofop-methyl 10%

[0029] Methamphetamide 5%

[0030] Sodium dodecylbenzenesulfonate 6%

[0031] Sorbitan Monostearate 3%

[0032] Alkyl succinate 5%

[0033] Fumed silica 1%

[0034] Magnesium Aluminum Silicate 1%

[0035] Dibutyl phthalate 10%

[0036] Methyl Oleate Fill up to 100%

[0037] The specific processing steps of the dispersible oil suspension concentrate of the composition are as follows: after dibutyl phthalate and saponin are mixed and dissolved according to the above formula, mineral oil, thickener and emulsifier are added to mix, and mixed by high speed shearing Uniformly, add cyhalofop-ethyl and mefenoxen respectively, continue shearing and mixing, and then grind in a horizontal sand mill, so that the particle size of the preparation is all below 10UM, and the 20% saliva described in the ...

Embodiment 3

[0038] Embodiment 3: when composition of the present invention is suspoemulsion, each component content is:

[0039] Saponin 7.5%

[0040] Cyhalofop-methyl 10%

[0041] Methamphetamide 4%

[0042] Methyl Oleate 13%

[0043] Alkylphenol Ethoxylate Phosphate 2%

[0044] Calcium dodecylbenzenesulfonate 5%

[0045] Alkylphenol Ether Phosphate 4%

[0046] Silicone 1.2%

[0047] pH regulator 0.2%

[0048] Xanthan Gum 0.2%

[0049] Ethylene glycol 4%

[0050] Deionized water make up to 100%

[0051] The concrete processing steps of described suspoemulsion are:

[0052] 1. According to the above formula, dilute saponin with methyl oleate, add an emulsifier and mix evenly to obtain an oil phase solution, and then add an appropriate amount of deionized water to emulsify with a homogenizer to obtain an emulsion.

[0053] 2. Mix the dispersant, thickener, and defoamer according to the above formula, mix evenly by high-speed shearing, add cyhalofop-methyl, continue shearing and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com