Preparation method of whole potato starch

A raw potato powder and potato technology, applied in the field of food processing, can solve problems such as uneven color and browning, affecting the quality of finished products, uneven color, etc., and achieve the effects of low water content, cost saving, and uniform color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

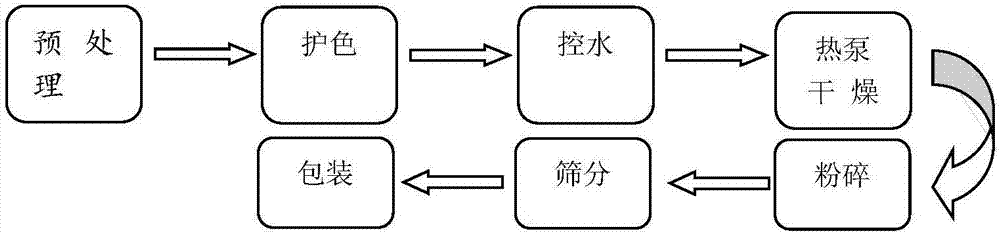

[0037] Embodiment one: the preparation method of whole potato powder

[0038] The invention provides a kind of preparation method of raw potato powder, specifically comprises the following technical steps:

[0039] (1) Pretreatment: Take mature and disease-free potatoes and dry them in the sun for 2h-4h, remove the attachments on the potato surface, clean them with a fruit and vegetable cleaning machine, peel them with a potato peeler, and cut them into cubes with a fruit and vegetable slicer Cube to get diced potatoes.

[0040] (2) Color protection: place the diced potatoes in step (1) in deoxygenated water for color protection, the water surface completely covers the diced potatoes, the temperature of the deoxygenated water is 17°C-21°C, and the color protection time is 20min-30min.

[0041] (3) Water control: take out the diced potatoes after the color protection treatment in step (2) with a strainer, and then control the water, and the water control time is 30s to 90s.

[...

Embodiment 2

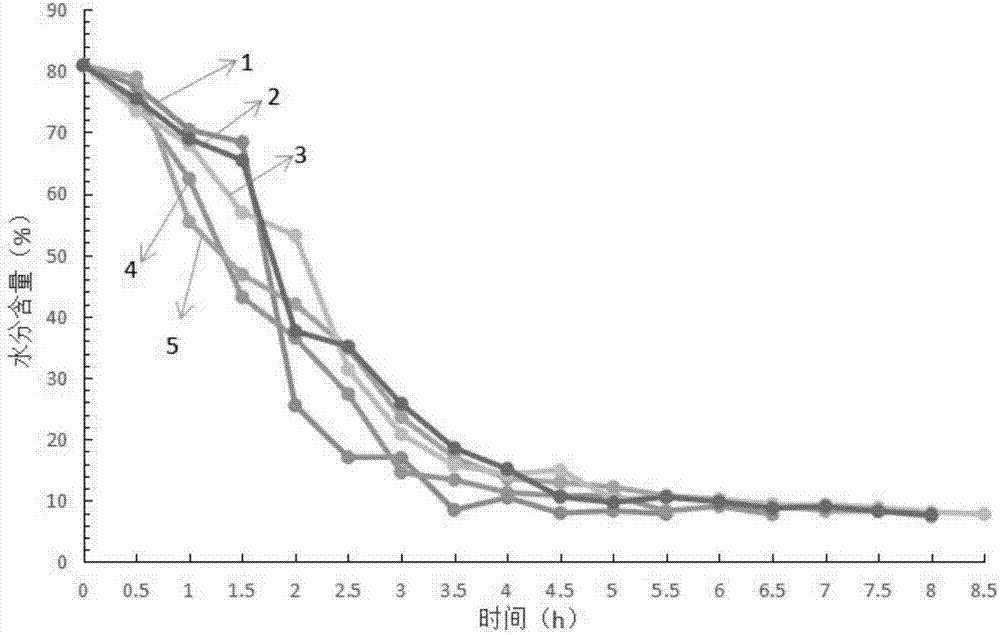

[0050] Embodiment two: the preparation method of raw potato powder

[0051] Take ripe, disease-free potatoes and dry them in the sun for 2 hours, remove the attachments on the surface of the potatoes, clean them with a fruit and vegetable cleaning machine, peel them with a potato peeler, and cut them into cubes with a fruit and vegetable cutter to obtain diced potatoes. Place in deoxygenated water for color protection. The water surface completely covers the diced potatoes. The temperature of the deoxygenated water is 17°C. The color protection time is 20 minutes. After the color protection treatment, the diced potatoes are fished out with a strainer and the water is controlled for 30 seconds. After water control, the diced potatoes are evenly spread on the drying tray in a single layer, and the drying tray is placed on a trolley and pushed into the heat pump drying room. The loading capacity of the diced potatoes is 200kg, and the temperature of the heat pump drying room is 40...

Embodiment 3

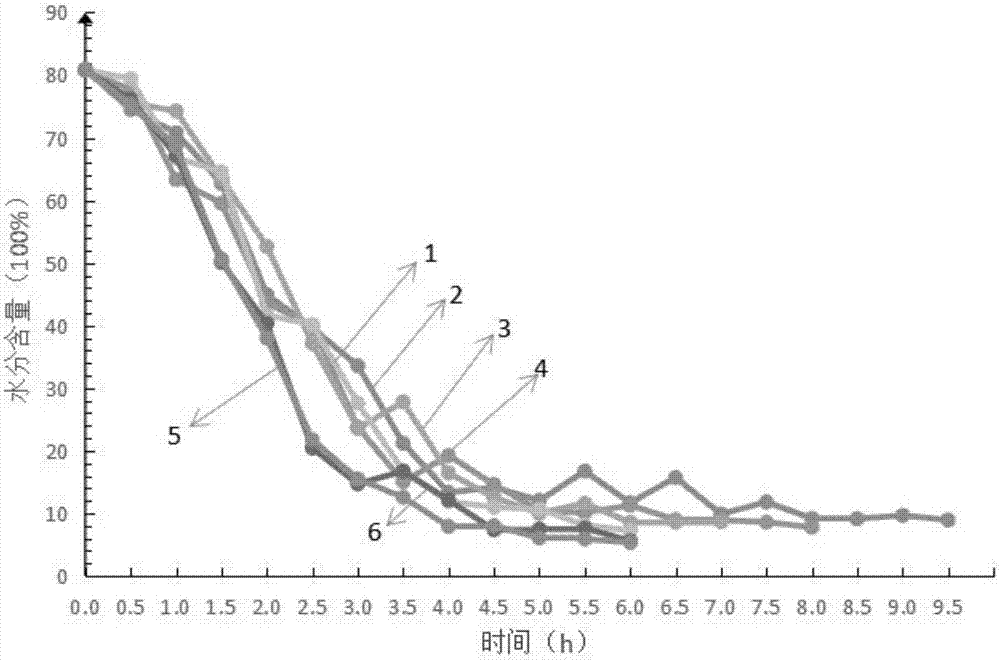

[0052] Embodiment three: the preparation method of raw potato powder

[0053] Take ripe, disease-free potatoes and dry them in the sun for 4 hours, remove the attachments on the surface of the potatoes, clean them with a fruit and vegetable cleaning machine, peel them with a potato peeler, and cut them into cubes with a fruit and vegetable cutter to obtain diced potatoes. Place in deoxygenated water for color protection. The water surface completely covers the diced potatoes. The temperature of the deoxygenated water is 21°C. The color protection time is 30 minutes. After the color protection treatment, the diced potatoes are taken out with a strainer and the water is controlled for 90 seconds. After water control, the diced potatoes are evenly spread on the drying tray in a single layer, and the drying tray is placed on a trolley and pushed into the heat pump drying room. The loading capacity of the diced potatoes is 1000kg, and the heat pump drying room temperature is 65 °C ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com