Preparation method of tin indium sulfide/squaraine composite visible light catalyst

A technology of indium tin sulfide and squaraine is applied in the field of photocatalysis and achieves the effects of easy control of preparation conditions, high catalytic efficiency and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

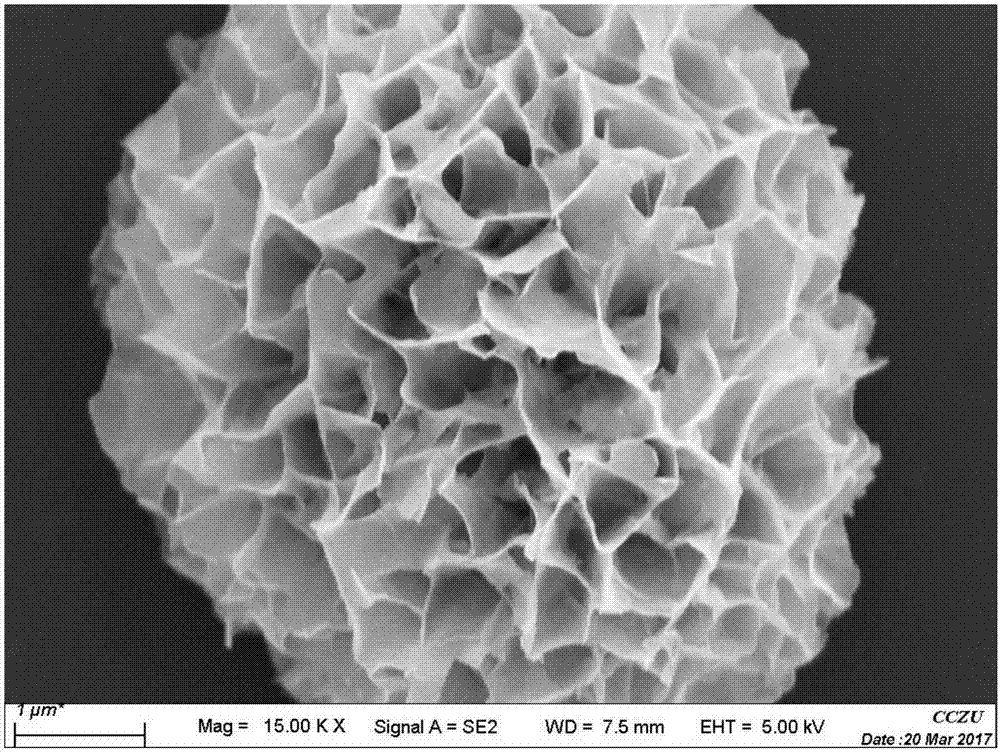

[0022] (1) Preparation of indium tin sulfide: Weigh 0.4207g of tin tetrachloride pentahydrate and 1.4088g of indium trichloride tetrahydrate, dissolve them in 96mL of absolute ethanol solution, stir until the solution is clear and transparent, add 0.7212 g of thioacetamide was continuously stirred for 30 minutes, then transferred into a high-pressure reactor, reacted at 160°C for 12 hours, cooled, washed and dried.

[0023] (2) Synthesis of symmetrical indole squaraine dyes: Weigh 0.145g N-2,3,3-trimethylindole and 0.052g squaraine into a three-necked flask, add 20mL n-butanol and 20mL Toluene mixed solvent, connect the condenser tube and the Stokes trap, and heat to reflux at 105°C for 10h. After the reaction, it was cooled to room temperature, vacuum-filtered and dried, and then separated and purified by column chromatography.

[0024] (3) Preparation of indium tin sulfide / squarine composite photocatalyst: Weigh 0.1g of indium tin sulfide in 30mL of absolute ethanol, 0.01g ...

Embodiment 2

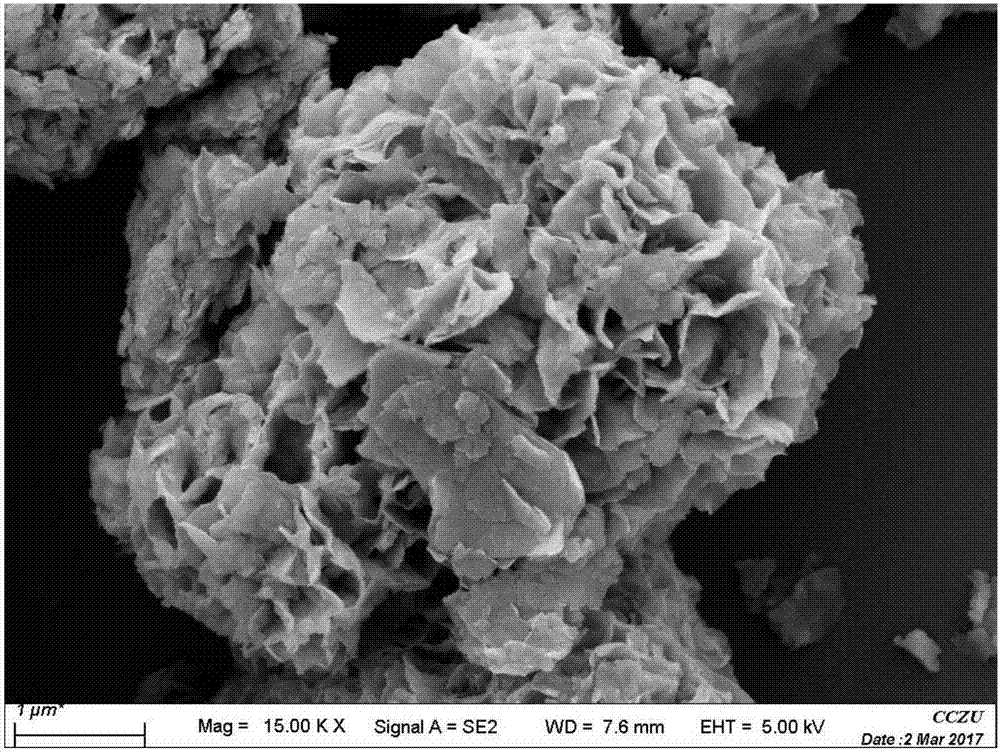

[0026] (1) Preparation of indium tin sulfide: Weigh 0.1728g of tin tetrachloride pentahydrate and 0.5786g of indium trichloride tetrahydrate, dissolve them in 40mL of absolute ethanol solution, stir until the solution is clear and transparent, add 0.2962 g of thioacetamide was continuously stirred for 30 minutes, then transferred into a high-pressure reactor, reacted at 160 degrees Celsius for 12 hours, cooled, washed and dried.

[0027] (2) Synthesis of symmetrical indole squaraine dyes: Weigh 0.145g N-2,3,3-trimethylindole and 0.052g squaraine into a three-necked flask, add 20mL n-butanol and 60mL Mix the solvent with toluene, connect the condenser tube and the Stokes trap, and heat to reflux at 115°C for 12h. After the reaction, it was cooled to room temperature, vacuum-filtered and dried, and then separated and purified by column chromatography.

[0028] (3) Preparation of indium tin sulfide / squarine composite photocatalyst: Weigh 0.1g of indium tin sulfide in 30mL of abs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| band gap | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com