Integrated induction melting gas atomization powder manufacturing device and gas atomization powder manufacturing method

A pulverizing device and induction smelting technology, which is applied in the field of gas atomization pulverization, can solve problems such as difficulty in fine powder particle size, reduction of powder usability, unfavorable atmosphere control, etc., to achieve convenient acquisition, lower gas atomization pressure, Good powder making effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] An integrated induction smelting gas atomization powder making device comprises an induction melting device and a gas atomization powder making device.

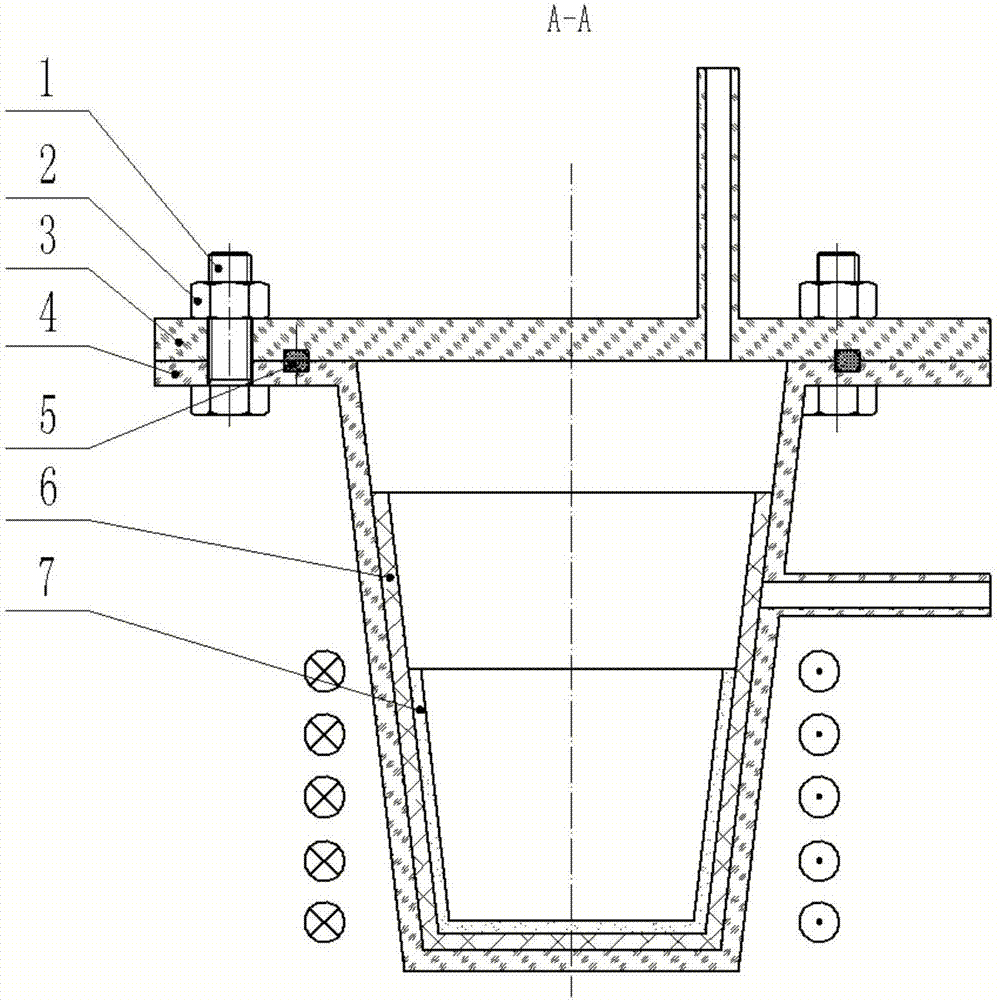

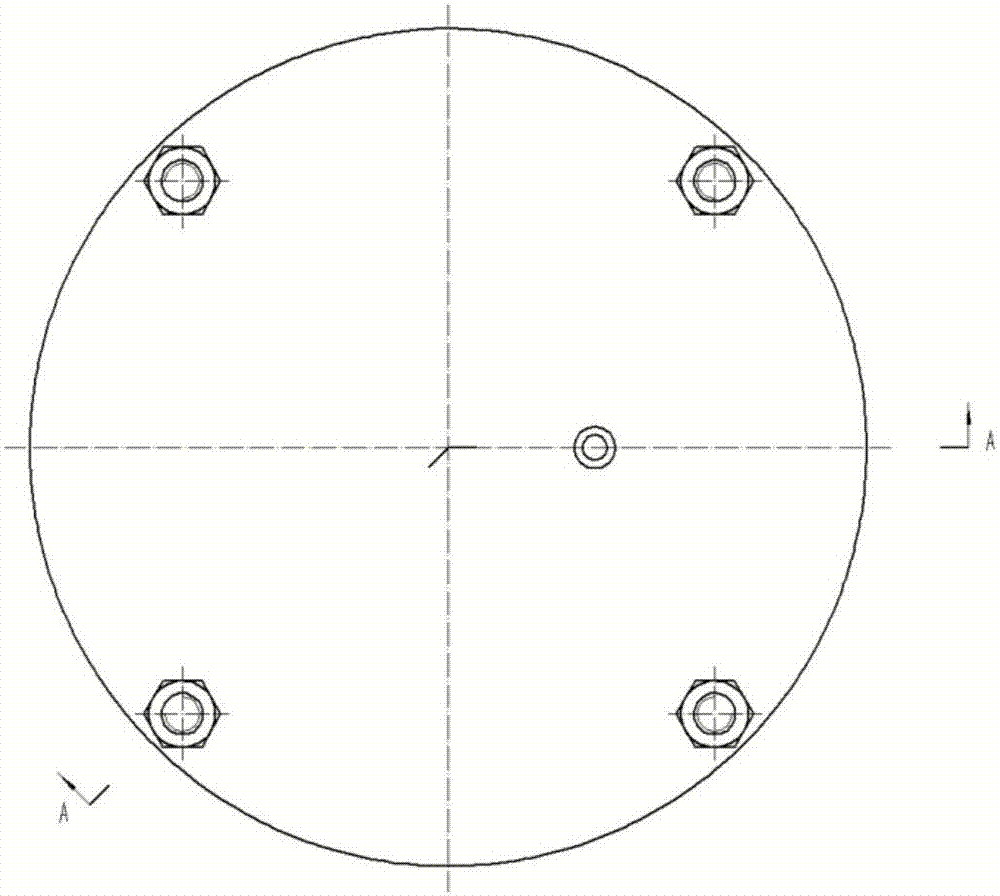

[0055] refer to Figure 1~Figure 2 , the induction melting device includes a melting quartz cup 4 and a melting quartz cover 3, both of which are sealed and assembled through an O-ring 5, a hexagonal bolt 1 and a hexagonal nut 2, and the melting crucible 7 is placed in the melting quartz cup 4, and the melting is carried out by silicic acid The aluminum cotton 6 is separated from the inner wall of the smelting quartz cup 4, and the outer wall of the smelting quartz cup 4 is coated with an induction coil to heat and melt the alloy.

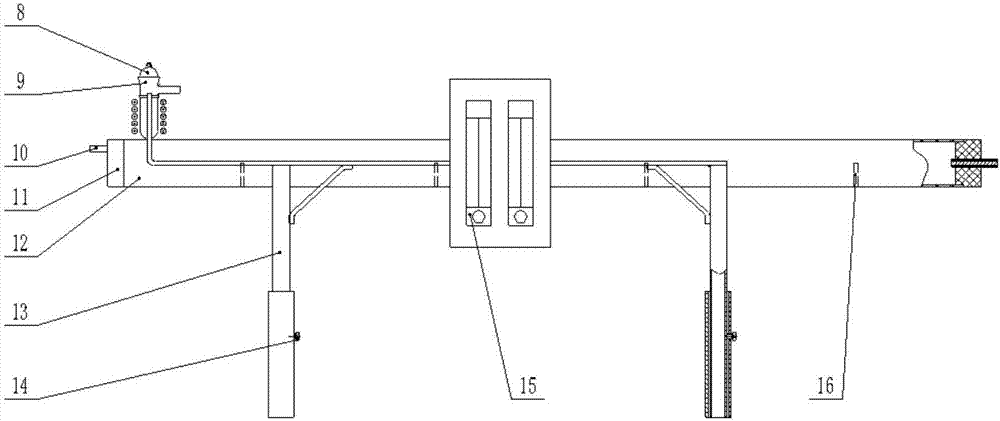

[0056] refer to Figure 3~Figure 5 , the gas atomization powder making device includes a support frame 13, the height of the support frame 13 is adjusted through the expansion and contraction of the internal steel pipe and with the screw 14; In the groove of the rack, it is used to collec...

Embodiment 2

[0066] The device and method of Example 1 were used to prepare Sn elemental metal powder. Cut pure Sn to within 10×10×20 mm size. Such as Figure 1~Figure 6 As shown, the following steps are taken:

[0067] Step S1: if Figure 1~Figure 6 As shown, unscrew the screw 14, adjust the height of the support frame 13, make the small hole opened in the quartz tube 12 closely contact with the nozzle 17 of the small gas atomization crucible 9, and rotate the solid silica gel plug 11 to make the porous corundum tube 10 empty Aim at the outlet of the nozzle 17 of the small gas atomization crucible 9, stick the solid silica gel plug 11 to the quartz tube 12 with adhesive tape, punch another hole and connect the solid silica gel plug 11 with an interference fit porous corundum tube in the hole Also taped to the quartz tube 12.

[0068] Step S2: Put a small piece of cut Sn in the gas atomization small crucible 9, cover the gas atomization small crucible cover 8, press it tightly with iro...

Embodiment 3

[0073] Adopt the device and method of embodiment 1 to carry out Cu-based Cu-Sn alloy powder preparation, as Figure 1~Figure 6 As shown, the following steps are taken:

[0074] Step S1: Put 39.1g of pure Cu and 60.9g of pure Sn in the smelting crucible 7, tighten the hexagonal nut 2, pass Ar gas into the smelting quartz cup 4, and pass through the gas outlet of the smelting quartz cup 4 and the outer water tank through four Fluorine tube connection to ensure better sealing. Turn on the induction heating equipment, turn off the induction heating equipment when the alloy is in a completely molten state and cool to a completely solidified state, repeat this three times, cool to room temperature, turn off the gas, take out the master alloy and cut it into a size of 10×10×20 mm.

[0075] Step S2: unscrew the screw 14, adjust the height of the support frame 13, make the small hole opened in the quartz tube 12 closely contact with the nozzle 17 of the small gas atomization crucible ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com