Composite system for rapidly and efficiently degrading organic dyestuff and preparation method

An organic dye, high-efficiency technology, applied in chemical instruments and methods, catalyst activation/preparation, water pollutants, etc., to achieve excellent degradation rate, solve secondary pollution, and not easy to lose the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

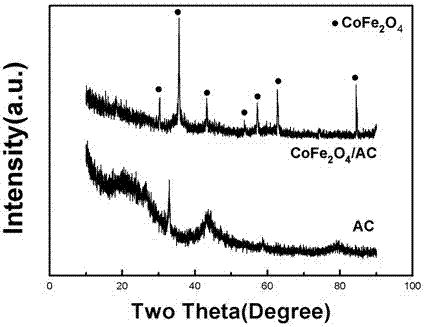

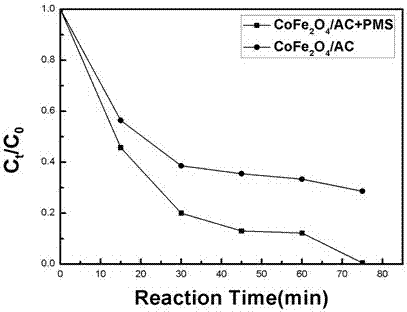

[0022] Specific implementation plan one: using CoFe 2 o 4 / AC-PMS composite system is a method for quickly and efficiently degrading organic dyes in water, specifically as follows: 1. Synthesis of CoFe by chemical co-precipitation 2 o 4 / AC composite material: Grind the activated carbon and pass it through a 200-mesh sieve. Use strong alkali (KOH) to modify the surface of the activated carbon by heating at 900°C for 10 hours in a nitrogen atmosphere, wash until neutral, and then dry it for later use. Weigh 0.008 mmoL FeCl 3 ·6H 2 O, 0.004 mmoL CoCl 2 ·6H 2 Dissolve O and 9.6g activated carbon in 100mL deionized water, stir magnetically for more than 12 hours, add 100mL1mol / L sodium hydroxide solution, continue stirring for a period of time to fully precipitate metal ions, filter and wash the precipitate to neutrality, and place it in blast drying Dry in the oven with 5% H 2 Calcined at 780°C for 4h in / Ar mixed gas, cooled to room temperature, ground and pulverized the ...

specific Embodiment approach 2

[0024] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the amount of activated carbon in Step 1 is 4.8 g, and the sintering conditions are 520° C. and 6 h. Others are the same as the first embodiment.

specific Embodiment approach 3

[0025] Specific embodiment three: the difference between this embodiment and specific embodiment one is: the amount of activated carbon in step one is 2.4g. Others are the same as the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

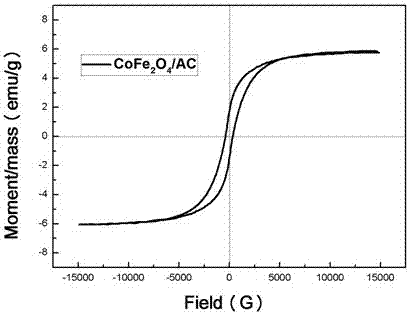

| Saturation magnetization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com