Bimetallic catalyst, preparation method and application thereof

A bimetallic catalyst and solvent technology, applied in the field of bimetallic catalyst and its preparation, can solve the problems of artificial addition, dust pollution, low functionality, etc., and achieve the effects of low unsaturation, narrow molecular weight distribution, and high catalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0052] The preparation method of the above-mentioned bimetallic catalyst, the zinc raw material and the alkali are fully stirred and mixed uniformly in proportion, the cobalt raw material is added and the cobalt raw material is fully stirred and mixed uniformly, filtered and cleaned, the obtained solid is added to the ligand and stirred at a high speed, left standing, and added The solvent is fully stirred and dispersed uniformly to obtain a bimetallic catalyst.

[0053] The preparation method of the bimetallic catalyst of the invention has simple process, low energy consumption and is suitable for large-scale production.

[0054] In a preferred embodiment of the present invention, the stirring time for fully stirring and mixing the zinc raw material and the alkali is more than 10 minutes, preferably 15-30 minutes, and more preferably 20 minutes.

[0055] In a preferred embodiment of the present invention, the stirring time for the cobalt raw material to be fully stirred and m...

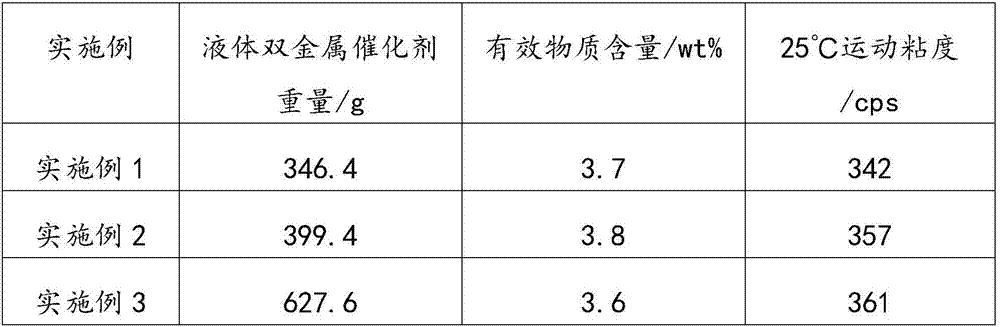

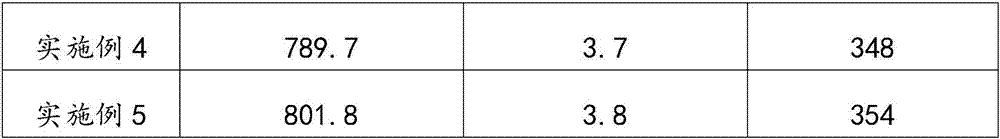

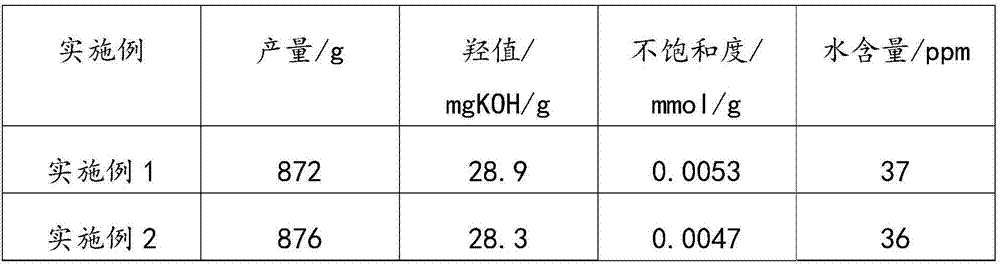

Embodiment 1

[0070] A preparation method of bimetallic catalyst, comprising:

[0071] Stir and drop the zinc chloride aqueous solution containing 20g of zinc chloride into the sodium hydroxide aqueous solution containing 0.5g of sodium hydroxide, and stir for 15min;

[0072] Then dropwise add potassium hexacyanocobaltate aqueous solution containing 20g potassium hexacyanocobaltate, and stir for 10min;

[0073] After vacuum filtration and cleaning, the obtained solid was added to 60 g of tert-butanol, and stirred for 30 min at a stirring rate of 6000 r / min;

[0074] After standing still for 24 hours, add 700g polyether 204, stir and shear emulsify for 10 minutes;

[0075] Dry and dehydrate under vacuum at 50°C to obtain a liquid bimetallic catalyst.

Embodiment 2

[0077] A preparation method of bimetallic catalyst, comprising:

[0078] Stir and drop the zinc chloride aqueous solution containing 40g of zinc chloride into the sodium hydroxide aqueous solution containing 5g of sodium hydroxide, and stir for 30min;

[0079] Then dropwise add the potassium hexacyanocobaltate aqueous solution containing 40g potassium hexacyanocobaltate, and stir for 30min;

[0080] After vacuum filtration and cleaning, the obtained solid was added to 80 g of tert-butanol, and stirred at 9000 r / min for 10 min;

[0081] After standing still for 60h, add 1000g polyether 305, stir and shear emulsify for 15min;

[0082] Dry and dehydrate under vacuum at 60°C to obtain a liquid bimetallic catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com