Carbon-based photo-thermal converting thin film, preparation method and application thereof and photo-thermal converting device

A light-to-heat conversion and thin-film technology, which is applied in the field of composite materials, can solve the problems of complex material assembly process, easy agglomeration, and high price, and achieve the effect of high-efficiency light-to-heat conversion performance and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The invention provides a method for preparing a carbon-based light-to-heat conversion film, comprising the following steps:

[0038] After mixing carbon black and ferrous acetate, microwave treatment is carried out under airtight conditions to obtain expanded carbon black;

[0039] Dispersing the expanded carbon black and the crosslinking agent in water to obtain an expanded carbon black dispersion;

[0040] A mixed cellulose filter membrane is used to filter out the moisture in the swollen carbon black dispersion, and the swelled carbon black and the mixed cellulose undergo a cross-linking reaction to obtain a carbon-based light-to-heat conversion film; the mixed cellulose filter membrane has a surface band There are amino groups.

[0041] In the invention, after mixing carbon black and ferrous acetate, microwave treatment is carried out under airtight conditions to obtain expanded carbon black. In the present invention, the mass ratio of the carbon black to ferrous ...

Embodiment 1

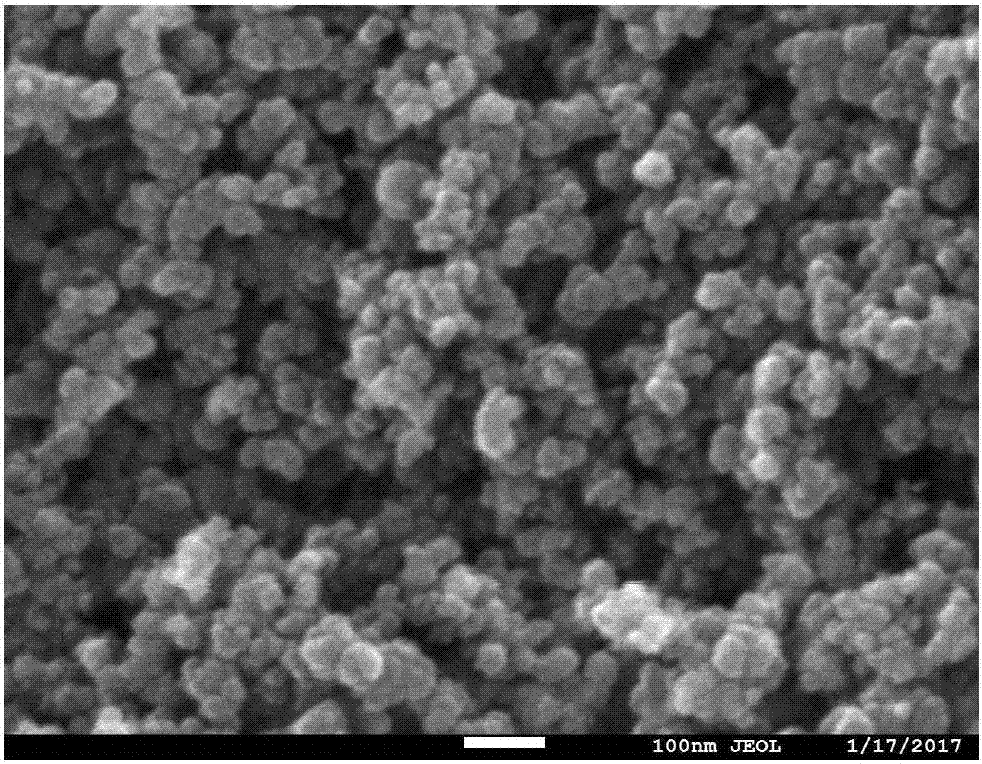

[0062] Pour 0.1156g of carbon black and 0.1156g of ferrous acetate into the grinder for grinding, then place the mixture in a sealed environment and put it into a microwave reactor at 900W, 300°C for 10s to obtain expanded carbon black;

[0063] Add 0.525g of polyethyleneimine and 0.015g of expanded carbon black to 2ml of deionized water, and ultrasonically disperse the mixture in an ultrasonic cleaner for 1 hour to obtain a uniform dispersion; subsequently, filter the dispersion under reduced pressure to a pore size of 0.45um The mixed cellulose filter membrane (membrane area is 20cm 2 ) to obtain a carbon-based light-to-heat conversion film (ECB / MCE).

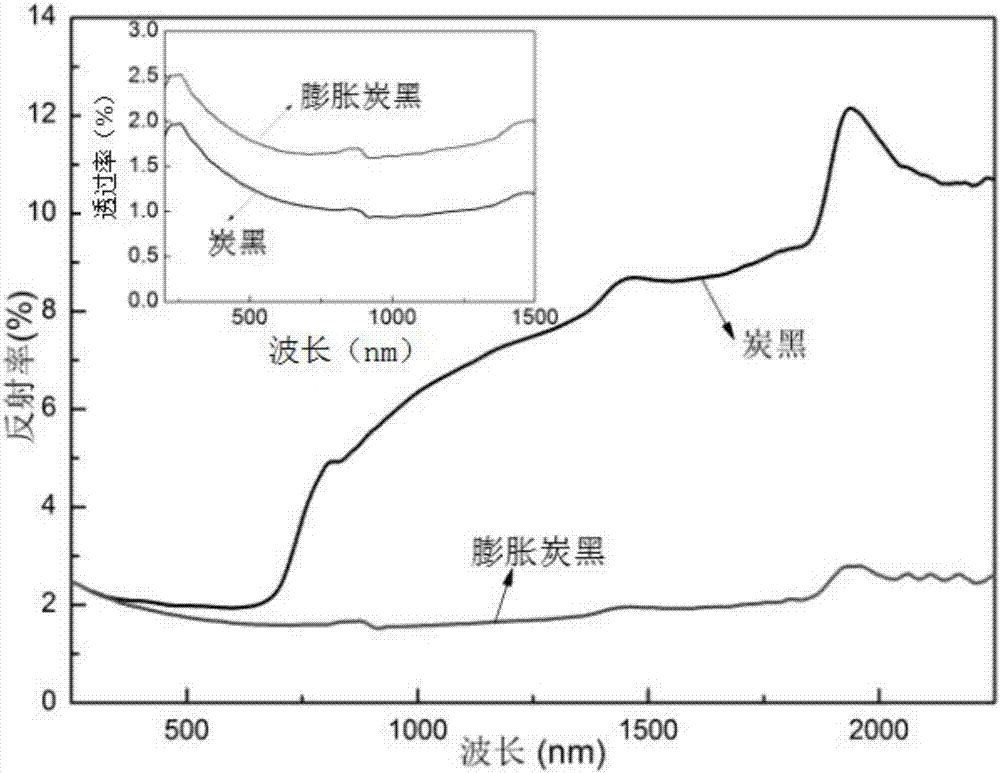

[0064] Use ultraviolet spectrometer to detect the carbon black before and after microwave treatment, the obtained results are as follows figure 1 shown; according to figure 1 It can be seen that the light transmittance of expanded carbon black to 200-1500nm is less than 3%, and the reflectivity of the entire sunlight is les...

Embodiment 2

[0069] Cellulose acetate paper (thickness 0.5mm) was used to wrap polystyrene foam (thickness 1.0cm), and the carbon-based light-to-heat conversion film prepared in Example 1 was placed on the upper surface of the cellulose acetate paper to obtain a light-to-heat conversion device (NES) .

[0070] The schematic diagram of the process for preparing the photothermal conversion device is as follows: Figure 5 shown;

[0071] Photothermal conversion performance test:

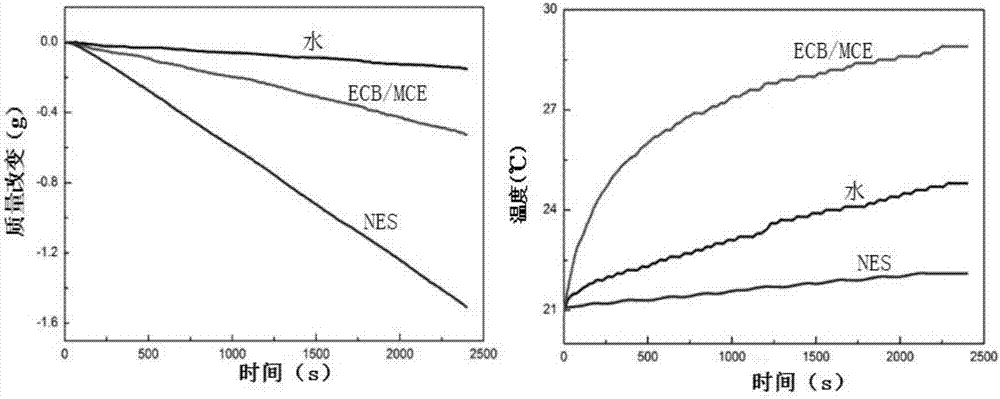

[0072] Experiment 1: Place the carbon-based light-to-heat conversion film (ECB / MCE) prepared in Example 1 and the light-to-heat conversion device (NES) prepared in this example on the water surface to conduct a light-to-heat conversion test, and control the light intensity to 1kW / m 2 , to detect the temperature and quality changes of water, the obtained results are as follows Image 6 as shown, Image 6 The quality and temperature change diagram of water when using carbon-based light-to-heat conversion film an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com