A crude oil electric dehydration device and method with a DC superimposed AC pulsed electric field

A technology of alternating current pulse and direct current superimposition, which is applied in the fields of electric/magnetic dehydration/emulsification, hydrocarbon oil treatment, petroleum industry, etc., and can solve electrochemical corrosion of electric dehydration equipment, collapse of electric field of bottom electrode, low effective utilization rate of electric energy, etc. problems, to achieve the effect of improving the efficiency of electric dehydration, fewer layers, and improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Below in conjunction with accompanying drawing, the present invention is described in detail:

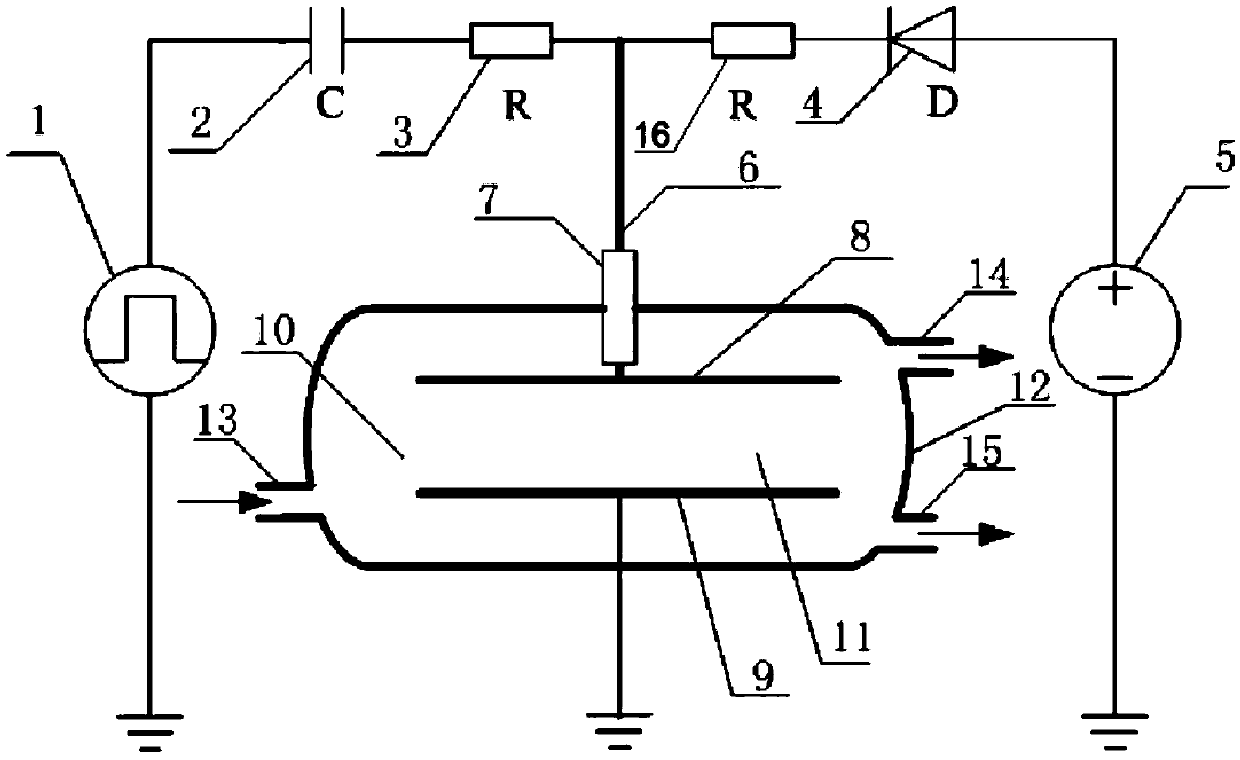

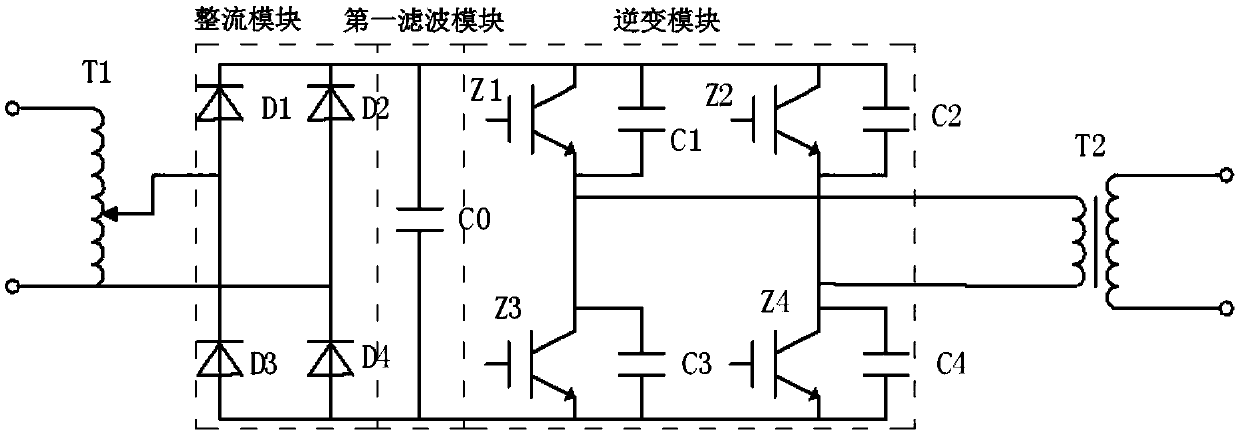

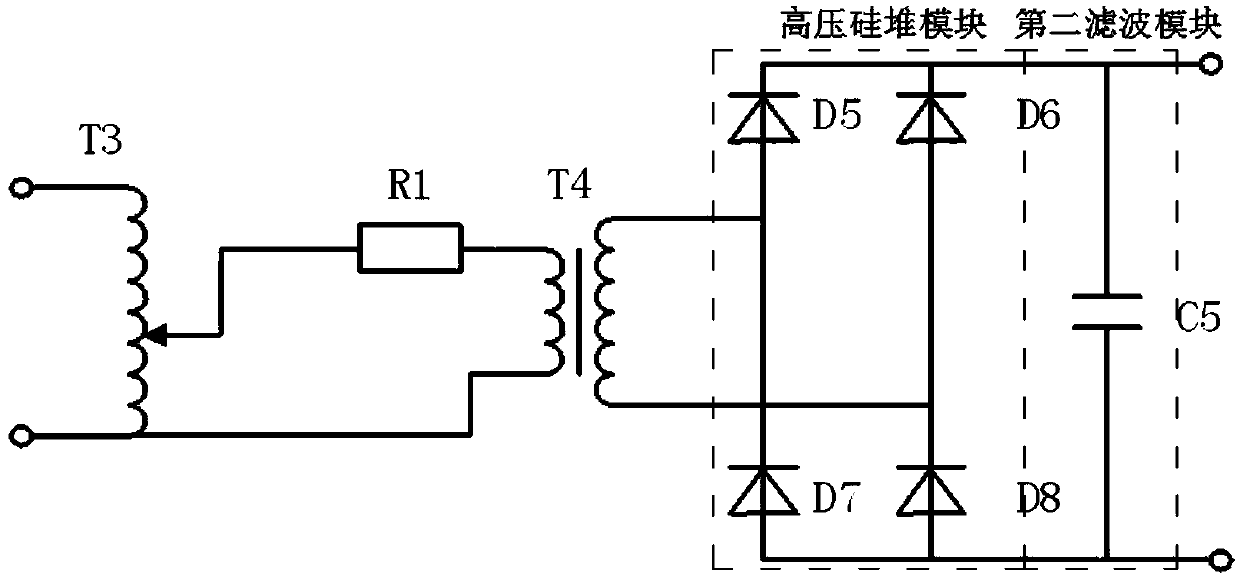

[0036] to combine Figure 1 to Figure 11 As shown, a crude oil electric dehydration device disclosed in this embodiment is a DC superimposed AC pulse electric field, including an AC pulse high-voltage power supply 1, a DC high-voltage power supply 5, and a crude oil electric dehydrator 12. The inside of the crude oil electric dehydrator 12 is parallel and spaced apart. A high-voltage electrode plate 8 and a grounding electrode plate 9 are arranged at a distance, an oil inlet 13 is arranged at one end of the bottom, a water outlet 15 is arranged at the bottom opposite to the oil inlet 13, and an oil outlet 14 is arranged above the water outlet 15 .

[0037] In this embodiment, the high-voltage electrode plate 8 and the ground electrode plate 9 are all stainless steel plates, and the high-voltage bushing 7 is a polytetrafluoroethylene bushing.

[0038] The crude oil emulsion 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com