Driving-and-control-integrated control system and control method for joint-type mechanical arm

A technology of control system and control method, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of limited load power, long time-consuming, high cost of INTEL-based industrial computer, improve real-time performance, and ensure smooth motion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The invention provides an integrated drive-control control system and control method for an articulated mechanical arm. The present invention will be described in detail below in conjunction with the accompanying drawings.

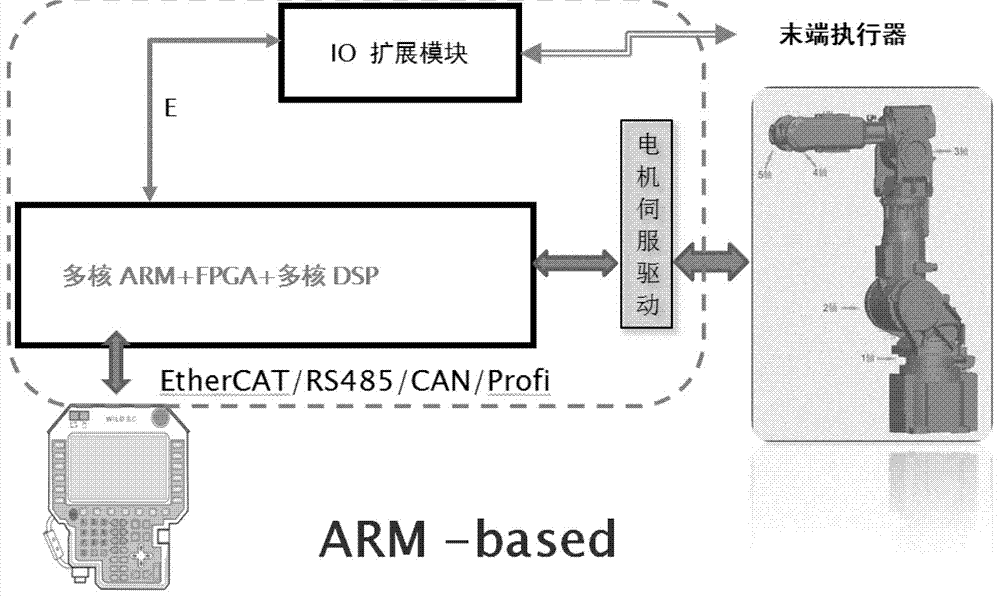

[0037] The invention utilizes one integrated ARM-DSP chip and two FPGA chips to complete the main control of the robot control system and the motion control of the motor. figure 1 It is the control system architecture diagram, as shown in the figure, the core part of the system on the physical module is the system main control board composed of multi-core ARM+DSP, FPGA, IO expansion module, motor servo drive module and Ethercat or RS485 or CAN or Profilebus network Bus communication interface.

[0038] figure 2 It is a structural diagram of the system hardware. As shown in the figure, the system hardware is mainly composed of the main control board, signal integration module, IPM drive amplifier module, and system strong current circuit contactor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com