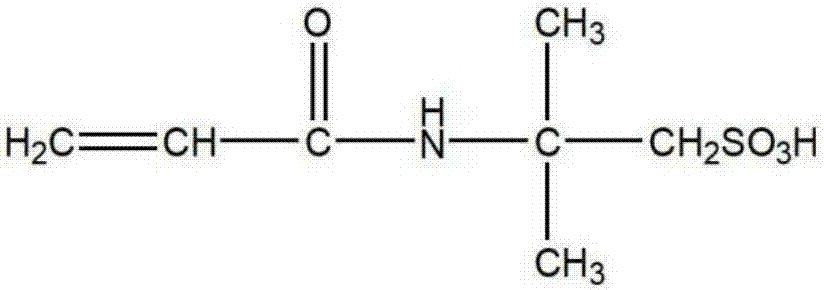

Process for reducing sulfate ions in synthesis process of 2-acrylamido-2-methylpropanesulfonic acid

A technology of methyl propanesulfonic acid and acrylamide group, which is applied in the chemical field to achieve the effects of low cost, high purity and low sulfate radical residues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Put 200kg of 0.12% acrylonitrile with water content and 1.2kg of acetic anhydride in a 0.5 cubic meter stainless steel reactor equipped with a jacket constant temperature device, agitator, thermometer, and liquid and gas feed distributor, and cool down to -15°C with refrigerated liquid While stirring, start to feed isobutene at a constant speed. When about 1.2kg of isobutene was introduced into the reactor, 40 kg of fuming sulfuric acid with a sulfur trioxide concentration of 0.42% prepared in advance was added dropwise. , and then feed 1.2kg of isobutene, and the total amount of isobutene fed is 24kg. The reaction process temperature was controlled at 35°C by passing cold water through the jacket. After 1.5 hours of heat preservation, the reaction was terminated, and the reaction solution was vacuum filtered. After filtering, a filter cake and a filtrate are obtained, the filtrate is recovered, and the filter cake is vacuum-dried at a drying temperature of 70° C. to ...

Embodiment 2

[0037] Put 200kg of 0.15% acrylonitrile with water content and 1.3kg of acetic anhydride in a 0.5 cubic meter stainless steel reactor equipped with jacket constant temperature device, agitator, thermometer and liquid and gas feed distributor, and cool down to -10°C with refrigerated liquid While stirring, start to feed isobutene at a constant speed. When about 1.5 kg of isobutene was passed into, 40 kg of fuming sulfuric acid with a sulfur trioxide concentration of 0.63% prepared in advance was added dropwise. While sulfuric acid was added dropwise, isobutene was continuously passed into the reactor. When the oleum was added dropwise, 2.0 kg of isobutene was fed in again, and the total amount of isobutene fed was 24 kg. The reaction process temperature was controlled at 40°C by passing cold water through the jacket. After 1.5 hours of heat preservation, the reaction was terminated, and the reaction solution was vacuum filtered. After filtering, a filter cake and a filtrate a...

Embodiment 3

[0040] Put 135kg of 0.2% acrylonitrile with water content and 1.3kg of acetic anhydride in a 0.5 cubic meter stainless steel reactor equipped with a jacket constant temperature device, agitator, thermometer, and liquid and gas feed distributors, and cool down to -5°C with refrigerated liquid While stirring, start to feed isobutene at a constant speed. When about 1.36 kg of isobutene was passed into, 31 kg of fuming sulfuric acid with a sulfur trioxide concentration of 0.5% prepared in advance was added dropwise. When sulfuric acid was added dropwise, isobutene was continuously passed into the reactor. When the oleum was added dropwise, 1.19kg of isobutylene was fed. The total isobutene feed was 17 kg. The reaction process temperature was controlled at 40°C by passing cold water through the jacket. After 1.5 hours of heat preservation, the reaction was terminated, and the reaction solution was vacuum filtered. After filtering, a filter cake and a filtrate are obtained, the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com