Antirust, wear-resistant, and environment-friendly sealing grease and preparation method thereof

A sealing grease, an environmentally friendly technology, applied in chemical instruments and methods, other chemical processes, petroleum industry, etc., to achieve good wear resistance, improve dispersion, and reduce health damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

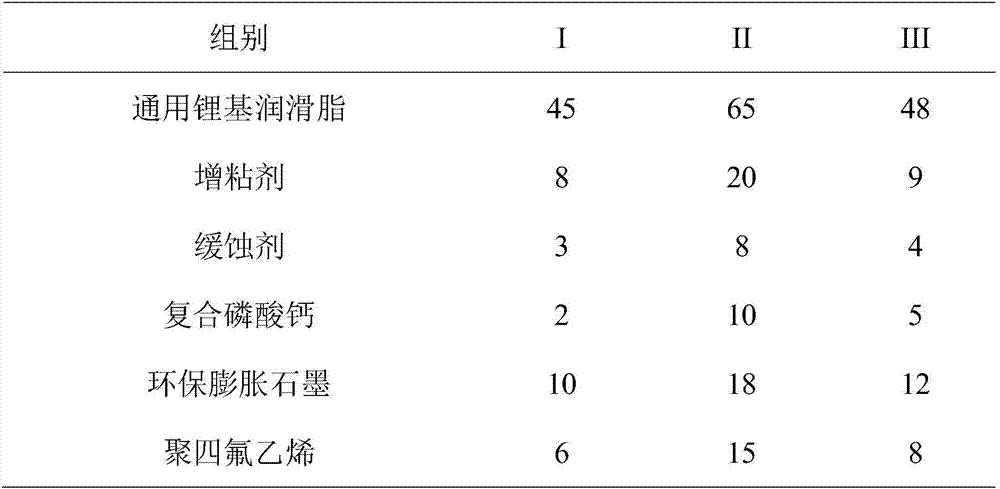

[0020] Embodiment 1: the preparation proportion of each raw material in the environment-friendly sealing grease of anti-rust and wear-resisting

[0021] The raw materials in the anti-rust and wear-resistant environment-friendly sealing grease were mixed according to the mass parts mentioned in Table 1 to obtain three groups of anti-rust and wear-resistant environment-friendly sealing grease I~III with different mixing ratios.

[0022] Anti-rust and wear-resistant environment-friendly sealing grease of different mixing ratios (mass parts) of table 1

[0023]

Embodiment 2

[0024] Embodiment 2: the preparation method of the environment-friendly sealing grease of anti-rust and wear-resisting

[0025] Step 1, the preparation of composite calcium phosphate: calcium carbonate is dissolved in water respectively to obtain solution A, phosphoric acid is dissolved in water to obtain solution B, the Ca / P molar ratio of described calcium carbonate and phosphoric acid is 1:0.5, and solution A is stirred Add it dropwise to solution B to obtain a mixed solution; use a regulator to keep the pH value of the mixed solution at 10-10.5, stir and react at room temperature for 8-10 hours, add a dispersant, age for 24 hours, wash the precipitate repeatedly with distilled water, Dry at 120°C for 2-12 hours; then raise the temperature to 600°C-1200°C at a heating rate of 5°C / min, and keep it warm for 0.5h-2h to obtain composite calcium phosphate.

[0026] Preparation of environmentally friendly expanded graphite: add nitric acid solution and potassium permanganate with...

Embodiment 3

[0029] Embodiment 3: the preparation method of the environment-friendly sealing grease of anti-rust and wear-resisting

[0030] Step 1, preparation of composite calcium phosphate: Calcium nitrate is dissolved in water respectively to obtain solution A, polyphosphoric acid is dissolved in water to obtain solution B, the Ca / P molar ratio of described calcium nitrate and polyphosphoric acid is 1:2, solution A Add it dropwise to solution B while stirring to obtain a mixed solution; use a regulator to keep the pH value of the mixed solution at 10-10.5, stir and react at room temperature for 8-10 hours, add a dispersant, age for 24 hours, and repeat the precipitation with distilled water Wash and dry at 120°C for 2-12 hours; then raise the temperature to 600°C-1200°C at a heating rate of 5°C / min, and keep it warm for 0.5h-2h to obtain complex calcium phosphate.

[0031] Preparation of environmentally friendly expanded graphite: add nitric acid solution and potassium dichromate with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com