Light-emitting diode epitaxial wafer and manufacturing method thereof

A technology of light-emitting diodes and epitaxial wafers, applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of low light-emitting efficiency of light-emitting diodes, and achieve the effects of facilitating lateral expansion, avoiding interface polarization, and improving effective doping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

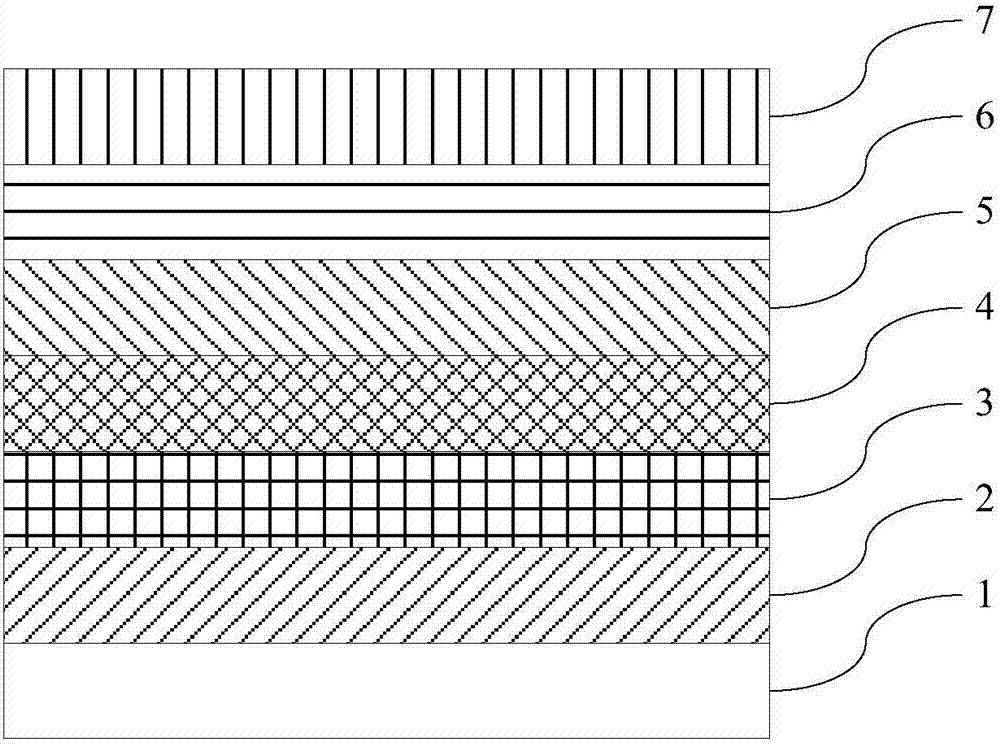

[0033] An embodiment of the present invention provides an epitaxial wafer of a light emitting diode, see figure 1 , the epitaxial wafer includes a substrate 1 and a buffer layer 2, an undoped gallium nitride layer 3, an N-type gallium nitride layer 4, a multi-quantum well layer 5, an electron blocking layer 6 and a P type GaN layer 7 .

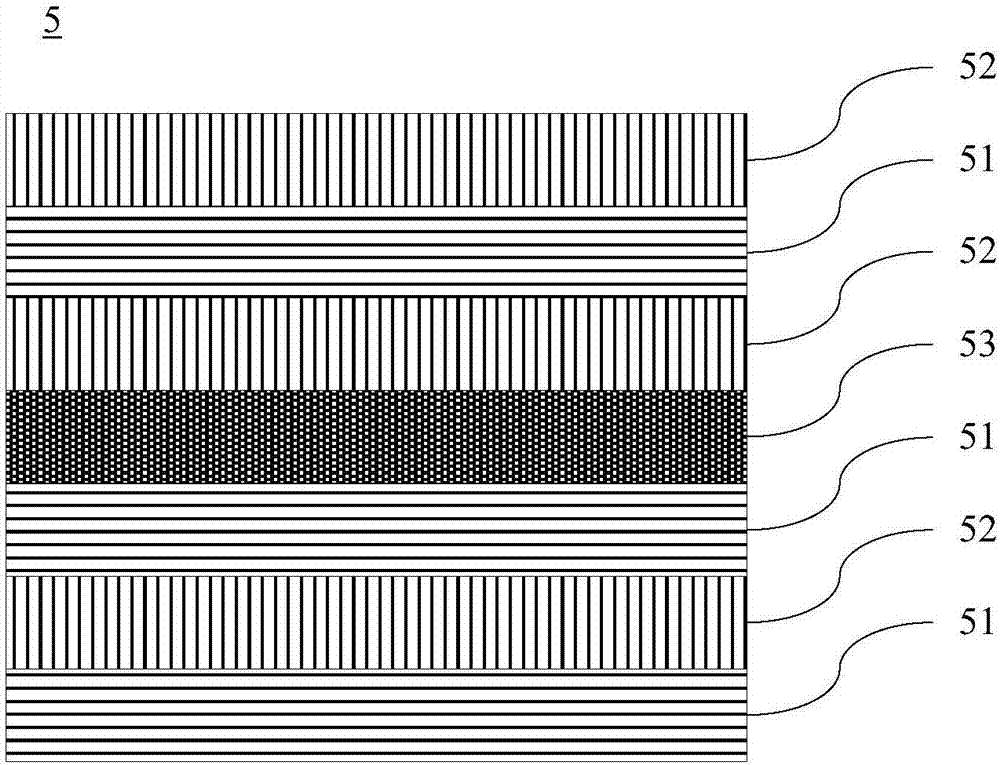

[0034] In this example, see figure 2 The multi-quantum well layer 5 includes a plurality of quantum wells 51 and a plurality of quantum barriers 52, the plurality of quantum wells 51 and the plurality of quantum barriers 52 are alternately stacked, and the quantum wells are InGaN layers. Multi-quantum well 5 also comprises at least one graphene film layer 53, and graphene film layer 53 is arranged between two adjacent quantum wells 51 and quantum barrier 52, when the quantity of graphene film layer 53 exceeds 1, phase At least one quantum well 51 or at least one quantum barrier 52 ( figure 2 Only take one graphene film layer as an example...

Embodiment 2

[0056] An embodiment of the present invention provides an epitaxial wafer of a light emitting diode, and the epitaxial wafer provided in this embodiment is a specific implementation of the epitaxial wafer provided in Embodiment 1.

[0057] In this example, if image 3 As shown, the multi-quantum well layer 5 includes 8 quantum wells 51 and 8 quantum barriers 52, and the junctions between each quantum well 51 and the adjacent quantum barrier 52 in the two quantum wells 51 closest to the electron blocking layer 6 are all provided. There is a graphene film layer 53 .

[0058] Experiments have found that the epitaxial wafer of the present embodiment is comparable to the traditional epitaxial wafer (the multi-quantum well layer includes 8 quantum wells and 8 quantum barriers, and the junction of each quantum well and the adjacent quantum barrier is not provided with a graphene film layer). ratio, the current density is 50A / cm 2 When the luminous efficiency is increased by 2%, the...

Embodiment 3

[0060] An embodiment of the present invention provides an epitaxial wafer of a light emitting diode, and the epitaxial wafer provided in this embodiment is another specific realization of the epitaxial wafer provided in Embodiment 1.

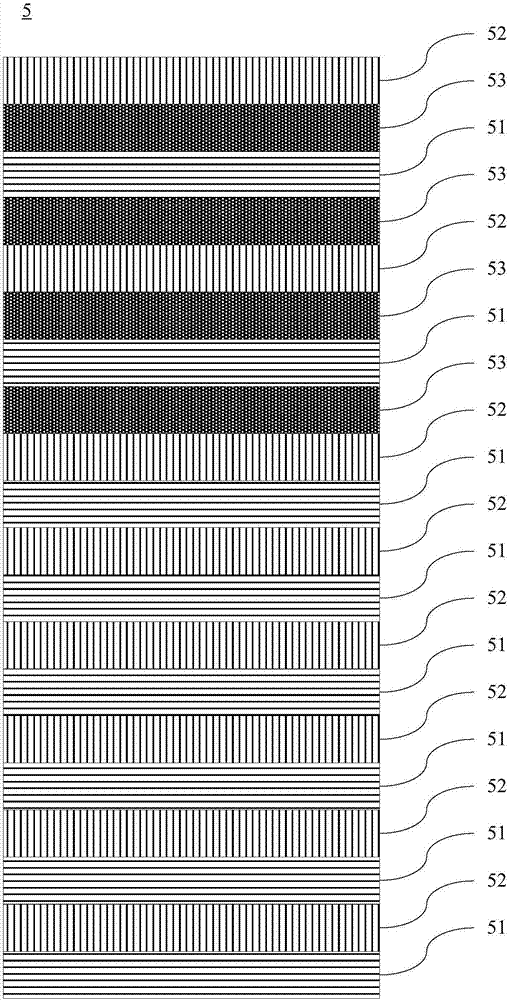

[0061] In this example, if Figure 4 As shown, the multi-quantum well layer 5 includes 8 quantum wells 51 and 8 quantum barriers 52, and the graphene film layer 53 is arranged at the junction of the quantum wells 51 and the quantum barriers 52, and between adjacent graphene film layers 53 Two quantum wells 51 and two quantum barriers 52 are provided.

[0062] Experiments have found that the epitaxial wafer of the present embodiment is comparable to the traditional epitaxial wafer (the multi-quantum well layer includes 8 quantum wells and 8 quantum barriers, and the junction of each quantum well and the adjacent quantum barrier is not provided with a graphene film layer). ratio, the current density is 50A / cm 2 When the luminous efficiency is in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Growth temperature | aaaaa | aaaaa |

| Growth pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com