Method for strengthening oil-polluted soil restoration by plant by utilizing mineralized refuse

A technology of mineralized garbage and restoration method, applied in the field of soil restoration, can solve the problems of low phytoremediation restoration efficiency and long restoration period, and achieve the effects of reducing soil ecotoxicity, reducing restoration cost, and expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Mineralized waste with a landfill age of 8 years was collected in the sanitary landfill of domestic waste, passed through a sieve with an aperture of 10 mm, and mineralized waste with a particle size of less than 10 mm was obtained for use.

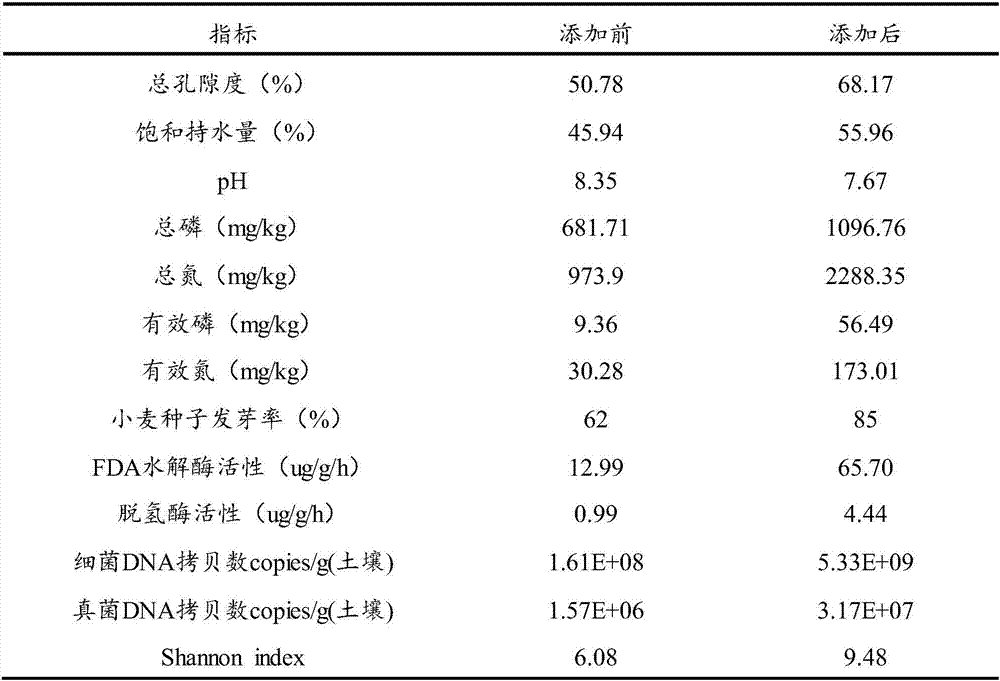

[0032] In air-dried petroleum-contaminated soil (petroleum hydrocarbon content 50g / kg), add the above-mentioned sieved mineralized garbage according to the mass ratio of mineralized garbage to petroleum-contaminated soil at a ratio of 1:1, and stir evenly. Table 1 shows the changes in the physical, chemical and biological properties of the contaminated soil before and after adding mineralized waste.

[0033] Table 1 Changes of soil physical, chemical and biological properties before and after adding mineralized waste

[0034]

[0035] From the data in Table 1, it can be seen that after adding mineralized waste, the ecotoxicity of the soil was greatly reduced, and the activity of petroleum hydrocarbon degrading enzymes, the numbe...

Embodiment 2

[0042] Mineralized waste with a landfill age of 8 years was collected in the sanitary landfill of domestic waste, passed through a sieve with an aperture of 10 mm, and mineralized waste with a particle size of less than 10 mm was obtained for use.

[0043] In air-dried petroleum-contaminated soil (petroleum hydrocarbon content 50g / kg), add the above-mentioned mineralized garbage after sieving according to the mass ratio of mineralized garbage to petroleum-contaminated soil at 1:9, 1:3, 1:1, and 3:1, Stir well.

[0044] After the mineralized waste is mixed with the petroleum-contaminated soil, the mixed soil is obtained, and the alfalfa seeds are soaked in 2% hydrogen peroxide for 20 minutes to be sterilized, washed and then evenly sown in the mixed soil, the seeding rate is 1.2kg / mu, and the upper part is covered with soil 0.5~1.0cm. At the same time, do non-mineralized waste control group (including plants).

[0045] After sowing, the temperature of the mixed soil was contr...

Embodiment 3

[0049] Mineralized waste with a landfill age of 8 years was collected in the sanitary landfill of domestic waste, passed through a sieve with an aperture of 10 mm, and mineralized waste with a particle size of less than 10 mm was obtained for use.

[0050] In air-dried petroleum-contaminated soil (petroleum hydrocarbon content 50g / kg), add the above-mentioned sieved mineralized garbage according to the mass ratio of mineralized garbage to petroleum-contaminated soil at a ratio of 1:1, and stir evenly.

[0051] After the mineralized waste is mixed with the petroleum-contaminated soil, the mixed soil is obtained, and the alfalfa seeds are soaked in 2% hydrogen peroxide for 20 minutes to be sterilized, washed and then evenly sown in the mixed soil, the seeding rate is 1.2kg / mu, and the upper part is covered with soil 0.5~1.0cm.

[0052] After sowing, the temperature of the mixed soil was controlled to be 25°C, and water was added regularly to maintain the mixed soil moisture cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com