Preparation method of guide vane of dot matrix cooling structure

A technology of guide vane and cooling structure, which is applied in the direction of additive manufacturing, mechanical equipment, process efficiency improvement, etc., and can solve problems such as difficult casting, unmanufacturable, and batch scrapping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0047] Preparation of K640 guide vanes with lattice structure in the cavity by laser selective melting:

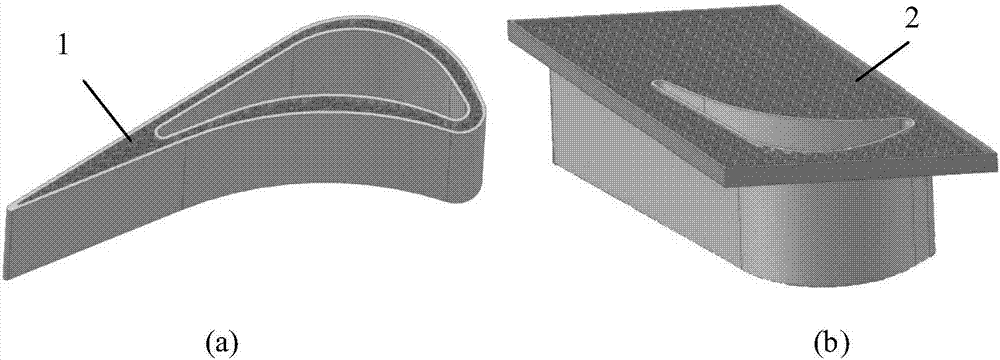

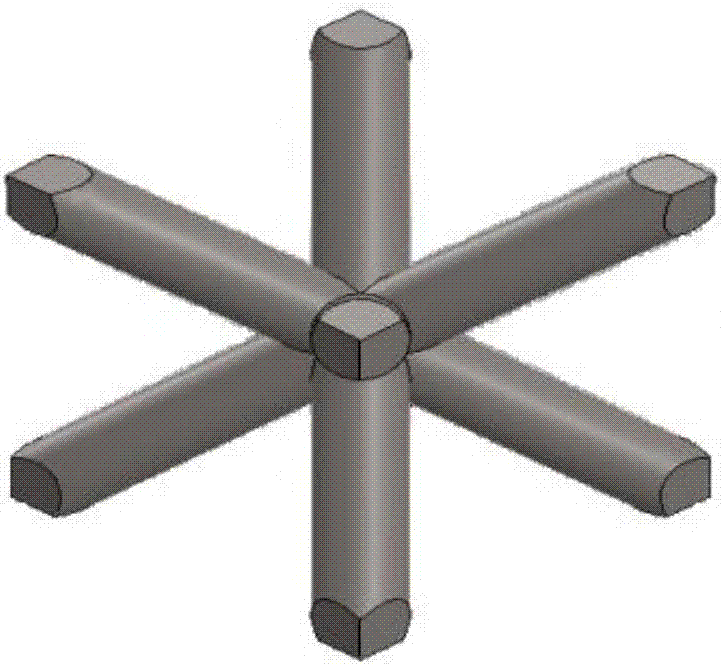

[0048] (1) Utilize three-dimensional drawing software (solidworks etc.) to set up the three-dimensional CAD model of the guide vane with lattice structure;

[0049] (2) According to the structural characteristics of the lattice in the guide vane with a new cooling structure, adjust the forming direction of the guide vane to ensure that all lattice units in the guide vane can be formed smoothly without adding support;

[0050] (3) According to the forming direction of the guide vane determined in step (2) and the structural characteristics of the guide vane, add forming auxiliary supports to the suspended part of the guide vane with an included angle of <45° with the forming surface;

[0051](4) Carry out layered slice processing on the guide vane in the forming direction, and evenly divide it into slices with a thickness of about 0.02-0.05 μm. The slice includes the cross-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com