Method for preparing polymer fluorescent nano particle

A fluorescent nanometer and polymer technology, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of complex preparation process and application limitations, and achieve the effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

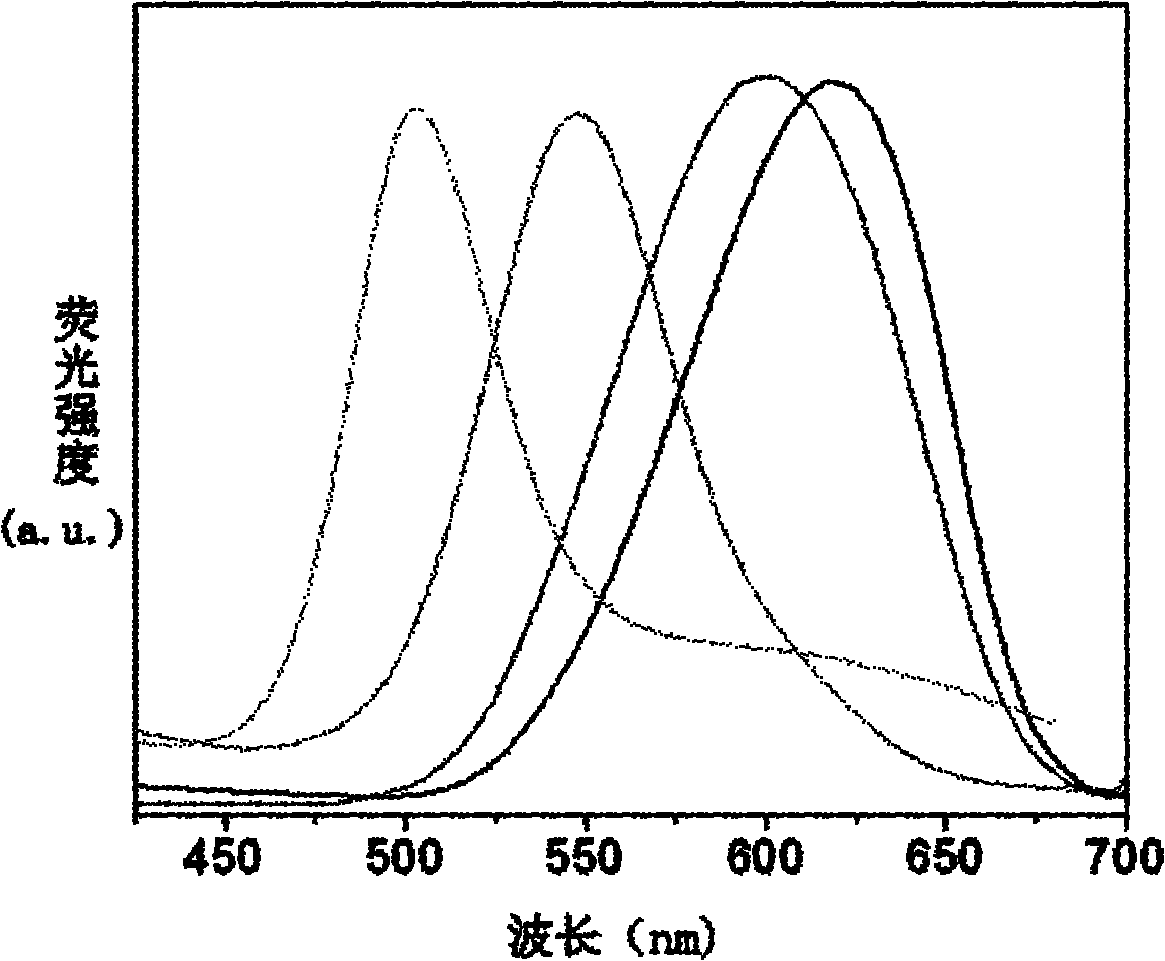

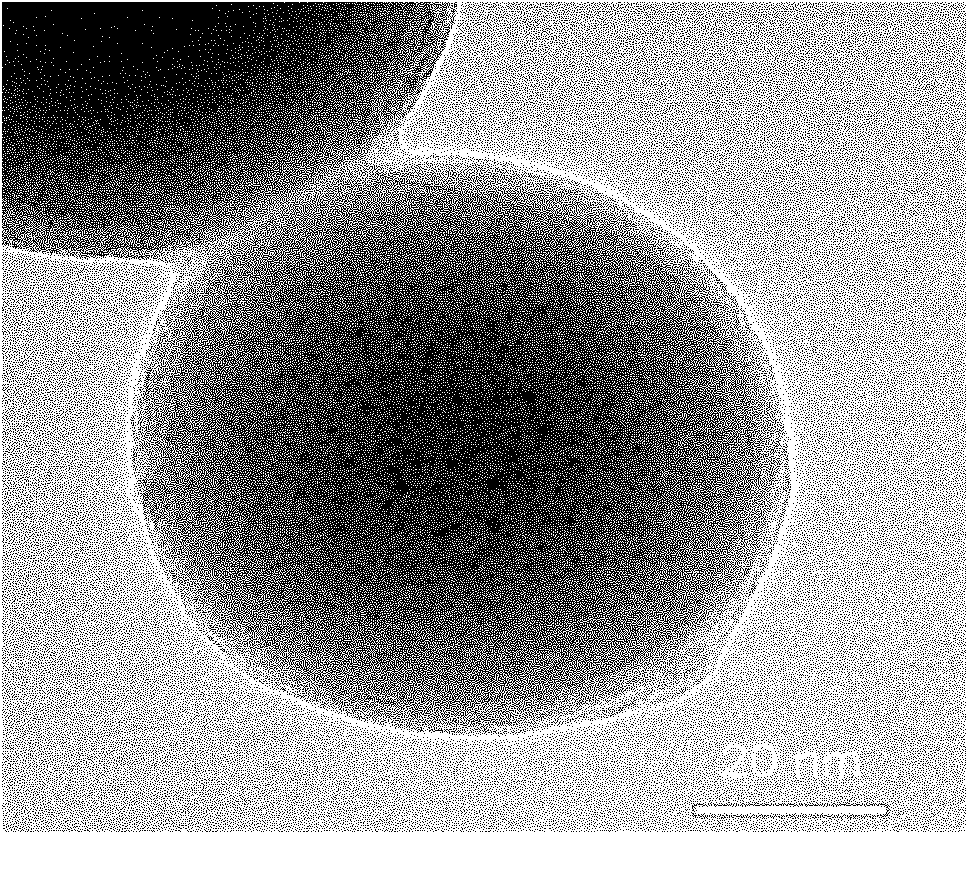

[0012] Specific embodiment one: a kind of preparation method of polymer fluorescent nanoparticle is to carry out according to the following steps: one, in the there-necked bottle of 500ml, add the selenium powder of 1.975g, the deionized water of 3.78g anhydrous sodium sulfite and 250ml, Under nitrogen condition, heat to 100 ℃~110 ℃ with oil bath, reflux 2~4 hours, after stopping heating, under the condition of flowing nitrogen, cool to room temperature, obtain colorless and transparent sodium selenosulfate solution; 2. Sodium hydroxide solution with a mass percent concentration of 6% to 8% and a mass percent concentration of cadmium acetate dihydrate solution with a mass percent concentration of 2% to 3% are sequentially added to a conical flask mixed with absolute ethanol and oleic acid, and the mixed liquid evolves It is white, then add the colorless and transparent sodium selenosulfate solution prepared in step 1 into the Erlenmeyer flask, then transfer it to a Teflon-lined...

specific Embodiment approach 2

[0017] Specific embodiment two: the difference between this embodiment and specific embodiment one is that in the step one, add the selenium powder of 1.975g, 3.78g anhydrous sodium sulfite and the deionized water of 250ml in the there-necked bottle of 500ml, under the nitrogen condition , start heating with an oil bath to 102°C to 108°C, stop heating after 2.5 to 3.5 hours of reflux, and cool to room temperature under the condition of blowing nitrogen to obtain a colorless and transparent sodium selenosulfate solution. Other steps and parameters are related to the specific Embodiment 1 is the same.

specific Embodiment approach 3

[0018] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that, in step one, add the selenium powder of 1.975g, 3.78g anhydrous sodium sulfite and the deionized water of 250ml in the there-necked bottle of 500ml, in logical nitrogen Under the conditions, start heating to 105° C. with an oil bath, stop heating after reflux for 3 hours, and cool to room temperature under nitrogen gas conditions to obtain a colorless and transparent sodium selenosulfate solution. Other steps and parameters are the same as those in the specific embodiment or two the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com