Preparation method of magnetic colloid core-shell structured gamma-Fe2O3 and Fe3O4

A core-shell structure and colloid technology, applied in the directions of ferrous oxide, iron oxide/iron hydroxide, iron oxide, etc., can solve the problem that the colloid has not been synthesized, and achieve the effect of simple and feasible method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Magnetic colloidal core-shell structure α-Fe 2 o 3 preparation of

[0021] Weigh 0.8mmol ferric chloride (FeCl 3 ·6H 2 O, analytically pure, Sinopharm Chemical Reagent Co., Ltd.) and 0.3 g of structure-directing agent glycine (analytical pure, Sinopharm Chemical Reagent Co., Ltd.) were dissolved in a mixed solution of 2 mL deionized water and 18 mL ethanol, and continuously Stir for 5min, then transfer the mixture to a 50mL polytetrafluoroethylene liner reactor, heat and react at 160°C for 12h, after the reaction is completed and naturally cool to room temperature, collect the precipitate by centrifugation, wash with ethanol several times, and then dry at 60°C Obtained magnetic colloidal core-shell structure α-Fe 2 o 3 .

Embodiment 2

[0023] Magnetic colloidal core-shell structure γ-Fe 2 o 3 preparation of

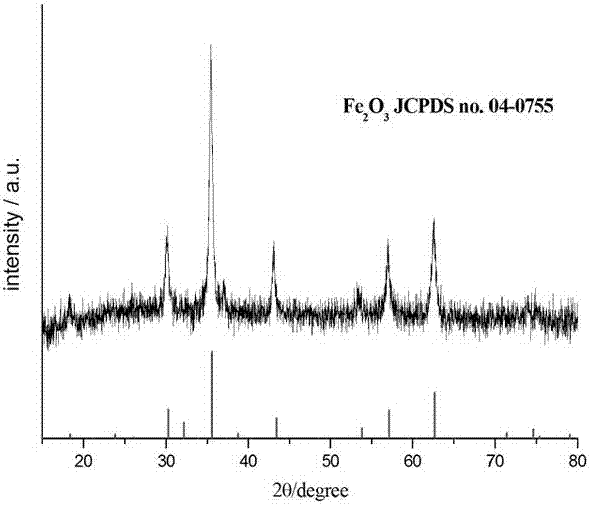

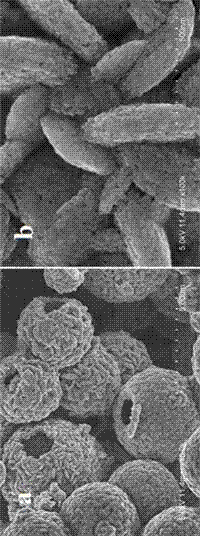

[0024] Weigh a certain amount of α-Fe 2 o 3 Placed in a nitrogen atmosphere (nitrogen purity 99.999%), heated to 600°C at a heating rate of 20°C / min and kept for 5 hours, and cooled naturally to room temperature to obtain the product. The XRD spectrum of the resulting product is as figure 1 , XRD pattern analysis showed that the sample was mixed with γ-Fe 2 o 3 (JCPDS no. 04-0755) each diffraction peak is completely corresponding, and there are no other miscellaneous peaks, indicating that the product obtained after heat treatment is pure phase γ-Fe 2 o 3 . Product SEM photo as figure 2 As shown, it can be seen that controlling the reaction temperature and calcination time can obtain γ-Fe with good morphology. 2 o 3 Core-shell structure. The core-shell structure is still a colloidal structure formed by the assembly of small particles as basic units.

Embodiment 3

[0026] Magnetic colloidal core-shell Fe 3 o 4 preparation of

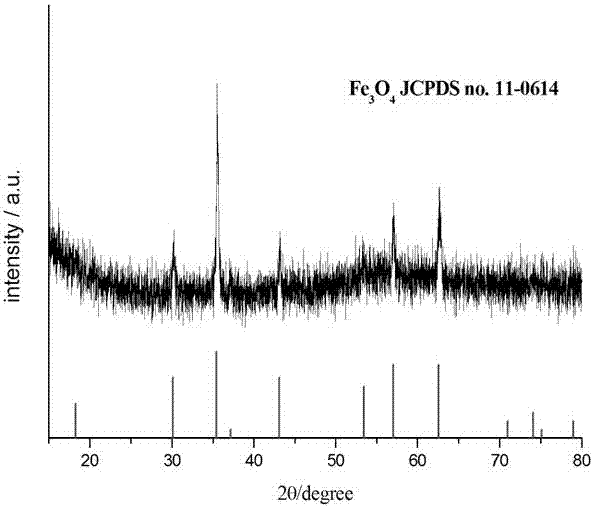

[0027] Weigh a certain amount of α-Fe 2 o 3 Place in a mixed atmosphere of hydrogen and argon (where the volume percentage of hydrogen is 5%), heat to 500°C at a heating rate of 30°C / min and keep it for 1h, and cool naturally to room temperature to obtain the product. The XRD pattern of obtained product is as image 3 As shown, with Fe 3 o 4 Compared with the standard spectrum (JCPDS no. 11-0664), all the diffraction peaks can correspond perfectly, and no other diffraction peaks exist, indicating that the obtained product is pure phase Fe 3 o 4 . The SEM photo of the resulting product is as Figure 4 Shown, enlarged SEM photographs ( Figure 4 b) It shows that the core-shell structure is still a colloidal structure formed by the assembly of small particles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com