Silicon nitride fiber reinforced silica and boron nitride ceramic matrix composite material and its preparation method and application

A technology for silicon nitride fibers and composite materials, applied in the field of ceramic matrix composite materials, can solve the problems of human toxicity, high price of boron nitride ceramic precursors, harsh molding and preparation conditions, etc., and achieves high viscosity at high temperature, which is conducive to densification. , the effect of reducing human toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

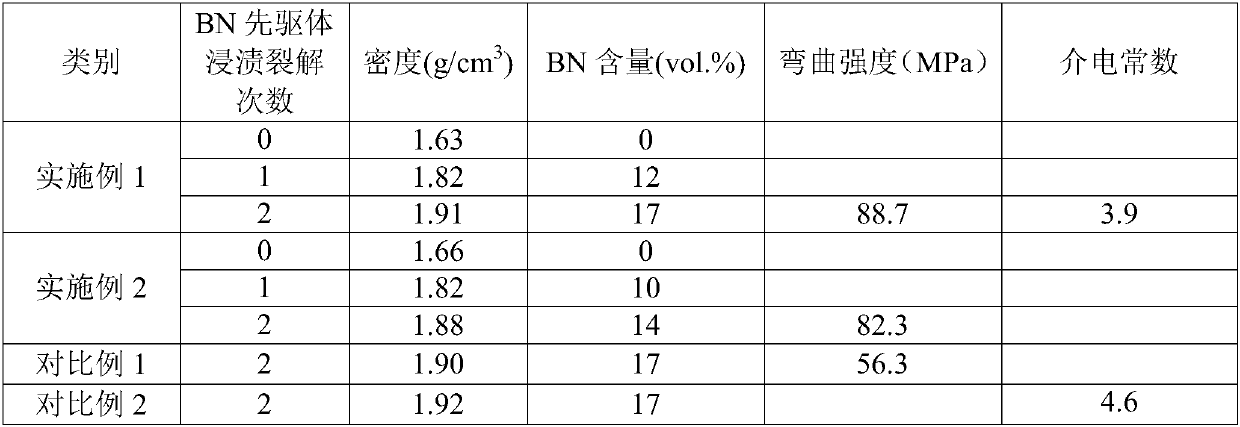

[0029] A kind of Si of the present invention 3 N 4f / SiO 2 -BN composites, including Si 3 N 4 Two-dimensional semi-Si with a fiber volume fraction of 35% prepared by weaving and piercing fiber bundles 3 N 4 Fiber preforms, and uniformly filled in the two-dimensional semi-Si 3 N 4 SiO in the pores of fiber preforms 2 Ceramic substrate and BN ceramic substrate. Among them, SiO 2 ceramic matrix in the Si 3 N 4f / SiO 2 -The volume fraction in the BN composite material is 43%, and the BN ceramic matrix is in the Si 3 N 4f / SiO 2 - The volume fraction in the BN composite is 17%.

[0030] A kind of Si of above-mentioned present embodiment 3 N 4f / SiO 2 -The preparation method of BN composite material, comprises the following steps:

[0031] (1) Preparation of fiber preform: Si 3 N 4 A two-dimensional silicon semi-nitride fiber preform with a fiber volume fraction of 35% is prepared by weaving and puncturing the fiber bundles.

[0032] (2) Debinding treatment: ...

Embodiment 2

[0038] A kind of Si of the present invention 3 N 4f / SiO 2 -BN composites, including Si 3 N 4 Three-dimensional Si with a fiber volume fraction of 33% prepared by weaving fiber bundles 3 N 4 Fiber preforms, and uniformly filled in the three-dimensional Si 3 N 4 SiO in the pores of fiber preforms 2 Ceramic substrate and BN ceramic substrate. Among them, SiO 2 ceramic matrix in the Si 3 N 4f / SiO 2 -The volume fraction in the BN composite material is 46%, and the BN ceramic matrix is in this Si 3 N4f / SiO 2 - The volume fraction in the BN composite is 14%.

[0039] A kind of Si of above-mentioned present embodiment 3 N 4f / SiO 2 -The preparation method of BN composite material, comprises the following steps:

[0040] (1) Preparation of fiber preform: Si 3 N 4 A three-dimensional silicon nitride fiber preform with a fiber volume fraction of 33% was prepared by braiding the fiber bundles.

[0041] (2) Debinding treatment: place the three-dimensional silicon ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com