Styrene acrylic emulsion containing ultralow VOC content and preparing method thereof

A styrene-acrylic emulsion and content technology, which is applied in the field of architectural coatings, can solve the problems of affecting the health of occupants, low stability between batches, and low production efficiency of products, and achieves reduction of residual monomer content, shortening of production cycle, and reaction. full effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

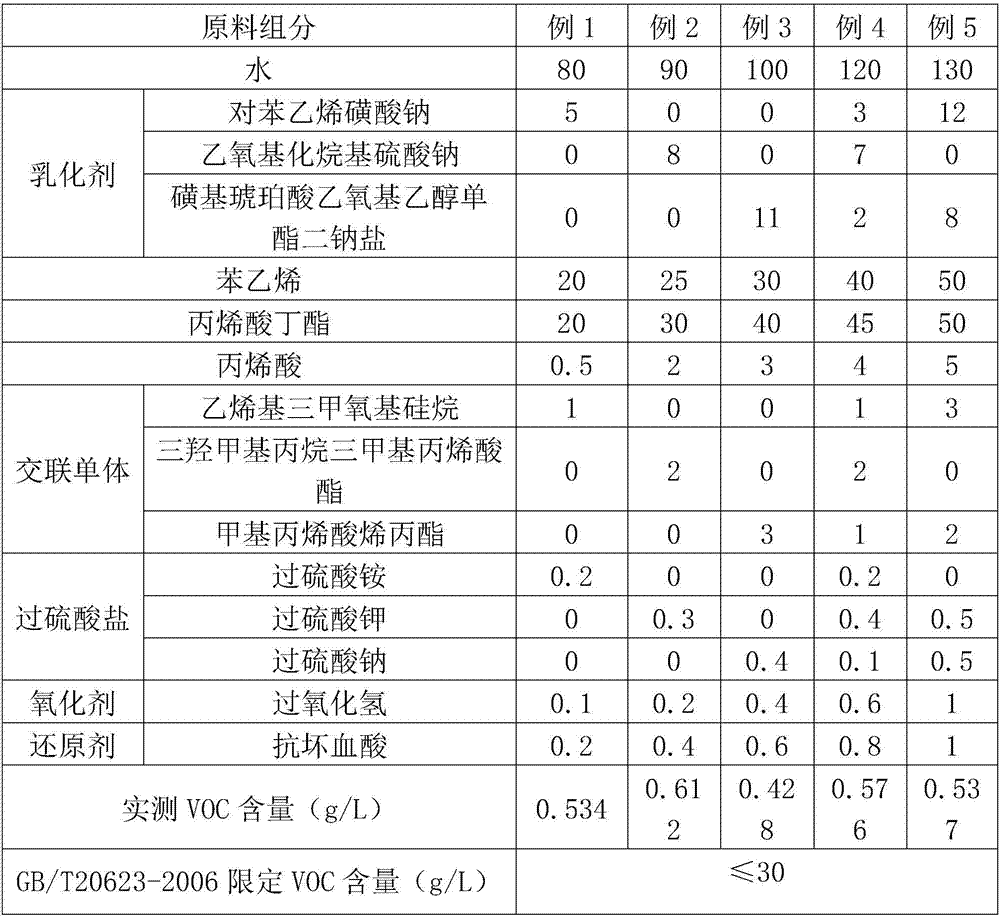

Examples

preparation example Construction

[0032] The preparation method of the ultra-low VOC content styrene-acrylic emulsion of the present invention comprises the following steps:

[0033] a) Under normal temperature and pressure, mix 2-10 parts of emulsifier and 10-20 parts of water in an emulsifying tank, after fully stirring and dissolving, add styrene, butyl acrylate, acrylic acid, cross-linking monohydrate in order and evenly stirred for 15-30 minutes to prepare a pre-emulsion for later use;

[0034] b) Add 40-50 parts of water and remaining emulsifier to the bottom of the reaction kettle, heat up to 80-95 ° C, and after the temperature is stable, put 10-15 parts of pre-emulsion in step a) at one time to prepare as seeds In the reaction kettle, after stirring for 0.5-1 minute, 0.1-0.5 part of persulfate initiator is fully dissolved with 2-10 parts of water and added to react, and the seeds are fully reacted for 10-30 minutes;

[0035] c) completely dissolving the remaining persulfate initiator with 5-15 parts ...

Embodiment 1

[0042] The ultra-low VOC content styrene-acrylic emulsion of the present invention comprises, in parts by mass: 80 parts of water, 5 parts of emulsifier, 20 parts of styrene, 20 parts of butyl acrylate, 0.5 part of acrylic acid, and 1 part of cross-linking monomer , 0.2 part of persulfate, 0.1 part of oxidizing agent and 0.2 part of reducing agent.

[0043] The emulsifier is sodium p-styrene sulfonate.

[0044] The crosslinking monomer is vinyltrimethoxysilane.

[0045] The persulfate is ammonium persulfate.

[0046] The oxidant is hydrogen peroxide.

[0047] The reducing agent is ascorbic acid.

[0048] The preparation method of the ultra-low VOC content styrene-acrylic emulsion of the present invention comprises the following steps:

[0049] a) Under normal temperature and pressure, mix 2 parts of emulsifier and 10 parts of water in an emulsifying tank, after fully stirring and dissolving, add styrene, butyl acrylate, acrylic acid, and cross-linking monomer in the formula ...

Embodiment 2

[0057] The ultra-low VOC content styrene-acrylic emulsion of the present invention comprises, in parts by mass: 90 parts of water, 8 parts of emulsifier, 25 parts of styrene, 30 parts of butyl acrylate, 2 parts of acrylic acid, and 2 parts of cross-linking monomers. , 0.3 part of persulfate, 0.2 part of oxidant and 0.4 part of reducing agent.

[0058] The emulsifier is sodium ethoxylated alkyl sulfate.

[0059] The crosslinking monomer is trimethylolpropane trimethacrylate.

[0060] The persulfate is potassium persulfate.

[0061] The oxidant is hydrogen peroxide.

[0062] The reducing agent is ascorbic acid.

[0063] The preparation method of the ultra-low VOC content styrene-acrylic emulsion of the present invention comprises the following steps:

[0064] a) Under normal temperature and pressure, mix 3 parts of emulsifier and 12 parts of water in an emulsifying tank. After fully stirring and dissolving, add styrene, butyl acrylate, acrylic acid, and cross-linking monomer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com