Modified talcum powder and preparation method thereof as well as polypropylene composite and preparation method thereof

A composite material and talc technology, applied in the field of modified materials, can solve problems such as intractability, and achieve the effect of preventing and avoiding agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

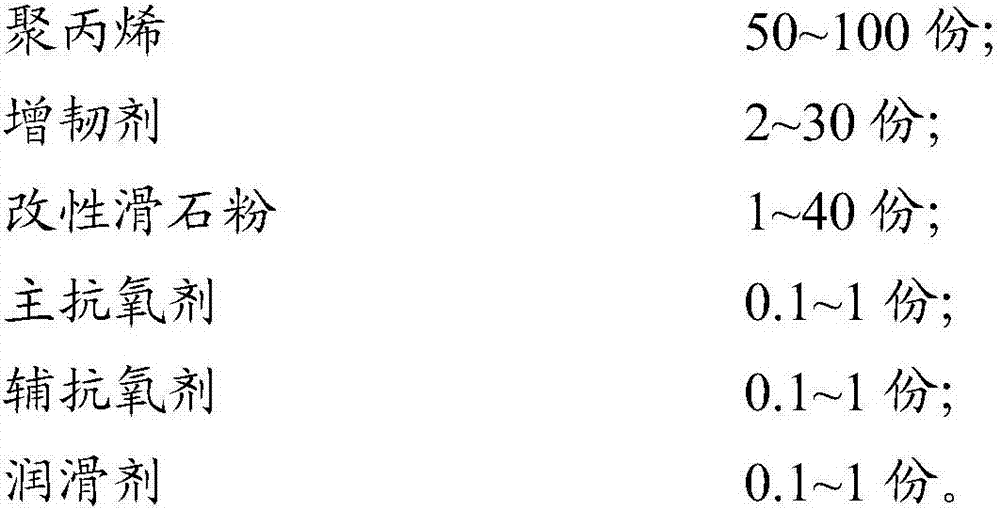

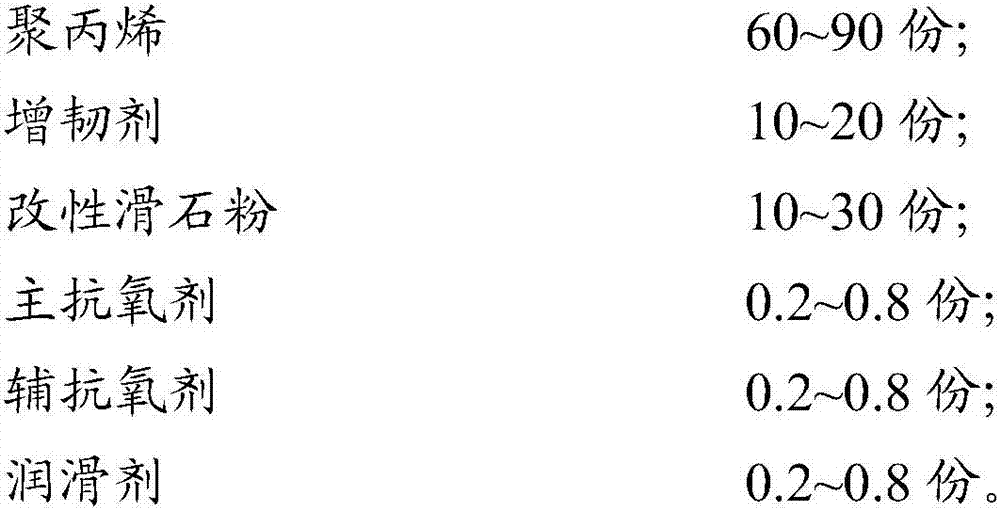

[0064] The present invention also provides a method for preparing the polypropylene composite material described in the above technical solution, comprising the following specific steps:

[0065] Dry blending a mixture comprising polypropylene, toughening agent, modified talc powder, primary antioxidant, secondary antioxidant and lubricant to obtain a dry blend;

[0066] The dry blend is melt-extruded to obtain a polypropylene composite material.

[0067] The invention dry mixes the mixture comprising polypropylene, toughening agent, modified talcum powder, primary antioxidant, secondary antioxidant and lubricant to obtain a dry mix. In the present invention, the dry blending is preferably performed in a high-speed mixer. In the present invention, the dry mixing speed is preferably 650 to 750 rpm, more preferably 670 to 730 rpm, most preferably 690 to 710 rpm; the dry mixing time is preferably 1 to 700 rpm. 4 minutes, specifically 1 minute, 2 minutes, 3 minutes or 4 minutes....

Embodiment 1

[0073] Mix 1 part monobasic sodium phosphate and 1 part water to make a pretreatment.

[0074] 100 parts of talcum powder and 1 part of pretreatment agent were mixed, and heat-treated at 120° C. at a high-speed stirring rate of 700 rpm for 30 minutes to obtain pretreated talc powder.

[0075] Mix 1 part of monoalkoxy phosphate titanate with 100 parts of the pretreated talc powder, and perform coupling treatment at a high-speed stirring rate of 700 rpm for 30 minutes to obtain modified talc powder.

Embodiment 2

[0077] Mix 1 part potassium monobasic phosphate and 1 part water to make a pretreatment.

[0078] 100 parts of talcum powder and 1 part of pretreatment agent were mixed, and heat-treated at 120° C. at a high-speed stirring rate of 700 rpm for 30 minutes to obtain pretreated talc powder.

[0079] Mix 1 part of monoalkoxy phosphate titanate with 100 parts of the pretreated talc powder, and perform coupling treatment at a high-speed stirring rate of 700 rpm for 30 minutes to obtain modified talc powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com