High-solid-content paint antiwrinkling diluent

A high-solids, thinner technology, used in coatings, polyurea/polyurethane coatings, etc., can solve problems such as wrinkles on the upper paint film, uneven drying speed, and unreasonable coating matching, achieving good applicability and lightening. Foaming, good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

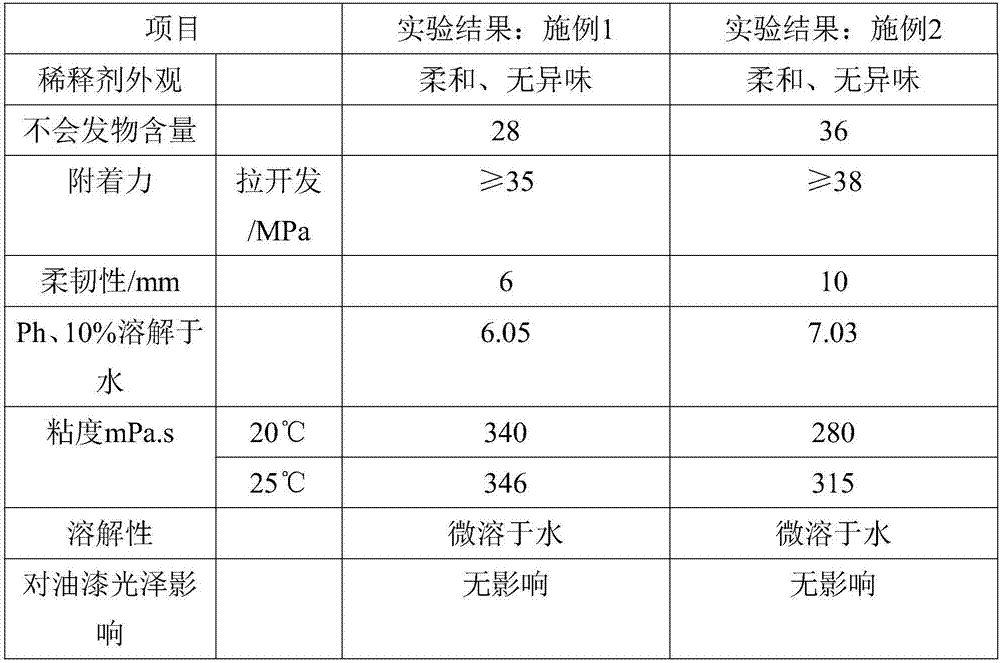

Examples

Embodiment 1

[0025] A high-solid paint anti-crease thinner:

[0026] The technical problem to be solved by the present invention is realized by the following technical solutions:

[0027] 26 parts of beeswax, 17 parts of lecithin, 21 parts of castor oil hydrogenation mixture, 19 parts of hydrocarbyl benzoate, 19 parts of carrageenan, 19 parts of cetyl stearate, 29 parts of dibutyl hydroxytoluene, diisostearate 27 parts of fatty acid esters, 9 parts of silicone resins, 1 part of Hercules, 3 parts of silicone oil, 13 parts of petrolatum, 35 parts of deionized water, 19 parts of tea tree oil, 16 parts of myristyl myristate.

[0028] The castor oil hydrogenation mixture is modified from castor oil, and the modification method is: adding 3 parts of turpentine, 2 parts of cationic polyacrylamide and 0.5 parts of polydimethyldiallyl chloride to 15 parts of castor oil After mixing thoroughly, microwave treatment at a microwave frequency of 2450MHz and a power of 700W for 5 minutes, then add 1 part of hy...

Embodiment 2

[0037] A high-solid paint anti-crease thinner:

[0038] 25 parts of beeswax, 19 parts of lecithin, 23 parts of castor oil hydrogenation mixture, 16 parts of hydrocarbyl benzoate, 25 parts of carrageenan, 19 parts of cetyl stearate, 39 parts of dibutyl hydroxytoluene, diisostearate 27 parts of fatty acid esters, 18 parts of silicone resin, 2 parts of Hercules, 1 part of silicone oil, 18 parts of Vaseline, 25 parts of deionized water, 19 parts of tea tree oil, 13 parts of myristyl myristate.

[0039] The castor oil hydrogenation mixture is modified from castor oil, and the modification method is: adding 3 parts of turpentine, 2 parts of cationic polyacrylamide and 0.7 parts of polydimethyldiallyl chloride to 20 parts of castor oil After mixing thoroughly, microwave treatment at a microwave frequency of 2450MHz and a power of 700W for 5 minutes, then add 1 part of hydrogenated castor oil, 1 part of sodium polystyrene sulfonate and 0.5 part of N-methyldiethanolamine, mix well and conti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com