Water-based quick drying anticorrosive storage-stable silver powder dipping paint and preparation method thereof

A technology of silver powder and impregnated paint, which is applied in the direction of anti-corrosion coatings and coatings, etc., which can solve the problems of poor appearance decoration effect and adhesion, poor storage stability of silver powder impregnated paint, rough arrangement of aluminum powder on the surface of workpieces, etc. , to achieve good use value, short drying time and good storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

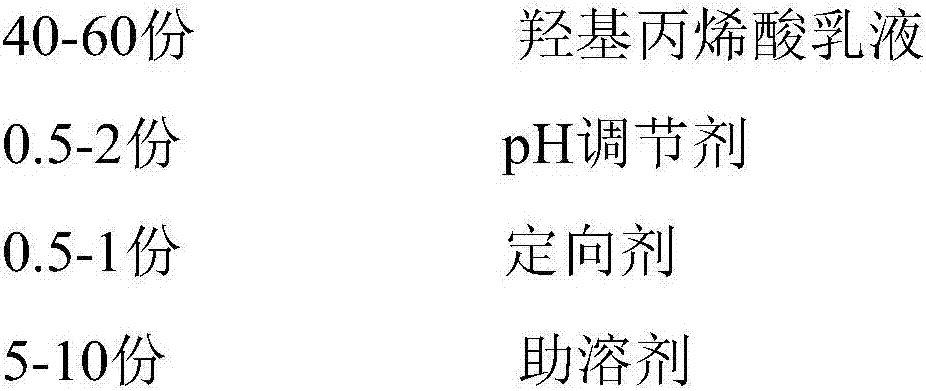

Method used

Image

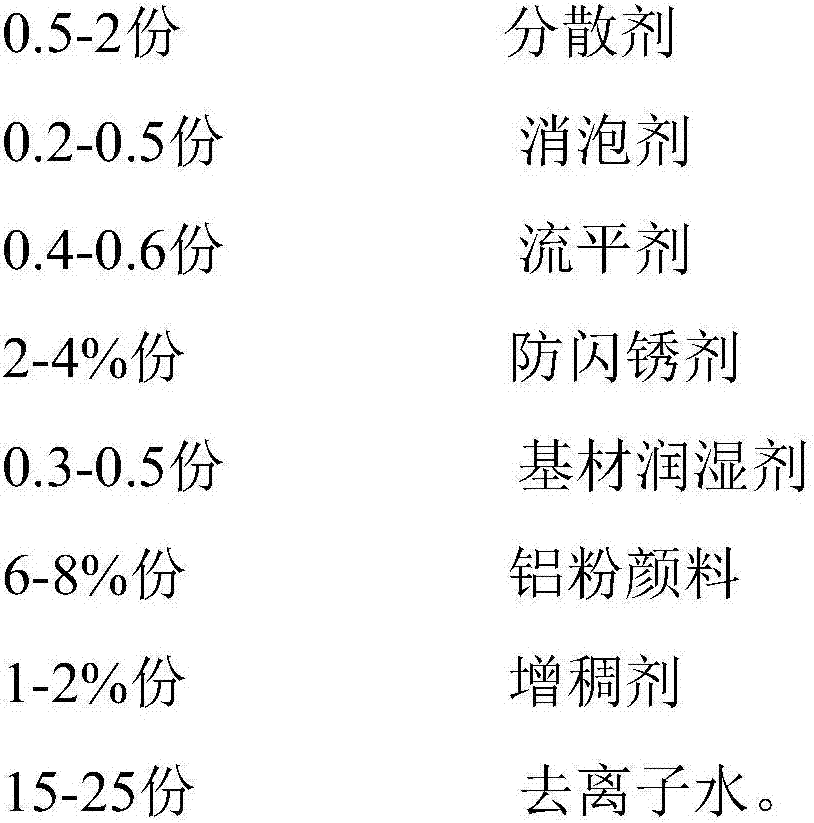

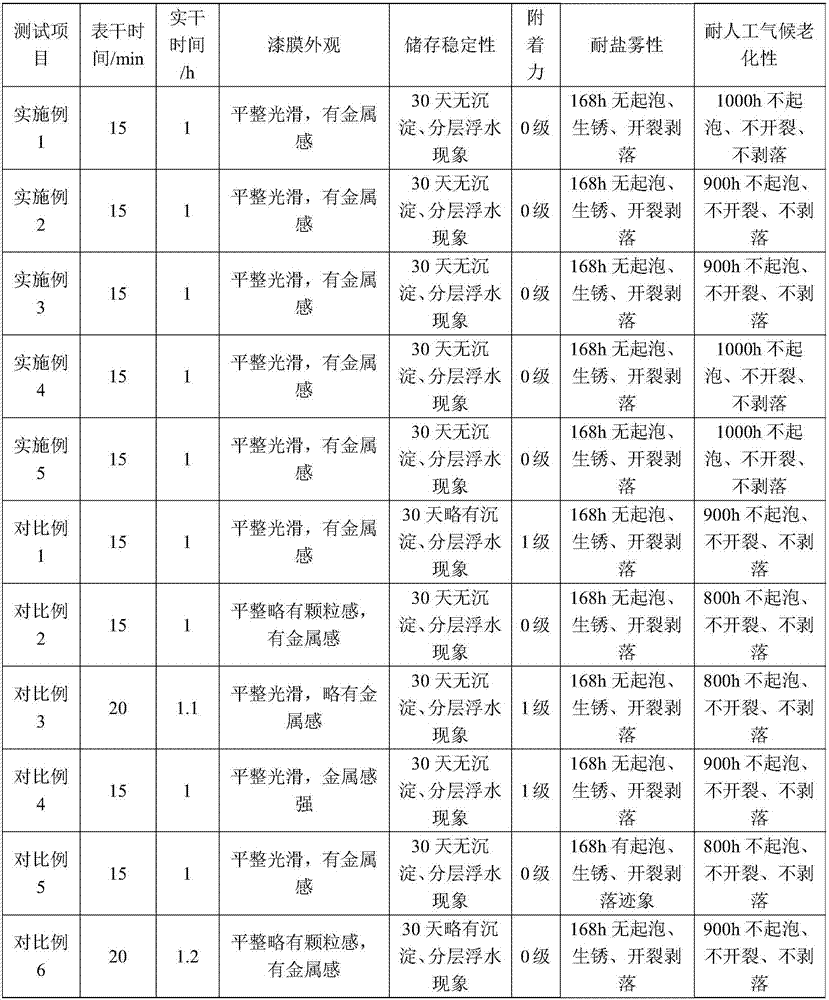

Examples

Embodiment 1

[0053] 20 parts of deionized water, 1 part of dispersant and 4 parts of co-solvent were stirred and mixed to form the first solution.

[0054] Add 50 parts of hydroxyacrylic acid emulsion, 4 parts of cosolvent, 1 part of pH adjuster, 0.8 part of directional agent, 0.4 part of antifoaming agent into the first solution to form the second solution, and the directional agent is obtained by adding 7 parts of butyl acetate Acid carboxymethyl cellulose ester was dissolved in 3 parts of ethylene glycol monobutyl ether, then 0.2 parts of alcohol amine was added, and finally 10 parts of deionized water was added to obtain a deionized water dispersion.

[0055] Add 7 parts of aluminum powder coated with silicon dioxide film into the second solution and stir evenly to form a paint solution, wherein the average thickness of the silicon dioxide film is about 3 nm, and the average particle size of the aluminum powder is about 8 μm.

[0056] Add 3 parts of anti-flash rust agent, 0.4 part of s...

Embodiment 2

[0059] 15 parts of deionized water, 0.5 parts of dispersant and 2 parts of co-solvent were stirred and mixed to form the first solution.

[0060] Add 40 parts of hydroxyacrylic acid emulsion, 3 parts of cosolvent, 0.5 part of pH regulator, 0.5 part of directional agent, 0.2 part of antifoaming agent into the first solution to form the second solution, and the directional agent is obtained by adding 5 parts of butyl acetate Acid carboxymethyl cellulose ester was dissolved in 3 parts of ethylene glycol monobutyl ether, then 0.1 part of alcohol amine was added, and finally 8 parts of deionized water were added to obtain a deionized water dispersion.

[0061] Add 6 parts of aluminum powder coated with silicon dioxide film into the second solution and stir evenly to form a paint solution, wherein the average thickness of the silicon dioxide film is about 2 nm, and the average particle size of the aluminum powder is about 12 μm.

[0062] Add 2 parts of anti-flash rust agent, 0.3 par...

Embodiment 3

[0065] 25 parts of deionized water, 2 parts of dispersant and 3 parts of co-solvent were stirred and mixed to form the first solution.

[0066] Add 60 parts of hydroxyacrylic acid emulsion, 4 parts of cosolvent, 2 parts of pH adjuster, 1 part of directional agent, 0.5 part of antifoaming agent into the first solution to form the second solution, and the directional agent is obtained by adding 6 parts of butyl acetate Acid carboxymethyl cellulose ester was dissolved in 3 parts of ethylene glycol monobutyl ether, then 0.2 parts of alcohol amine was added, and finally 10 parts of deionized water was added to obtain a deionized water dispersion.

[0067] Add 8 parts of aluminum powder coated with silicon dioxide film into the second solution and stir evenly to form a paint solution, wherein the average thickness of the silicon dioxide film is about 5 nm, and the average particle size of the aluminum powder is about 5 μm.

[0068] Add 4 parts of anti-flash rust agent, 0.5 part of s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average thickness | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com