Automatic koji inoculating machine

A kind of koji planting machine and automatic technology, which is applied in biochemical instruments, biochemical equipment and methods, enzymology/microbiology devices, etc., can solve problems such as low efficiency, deviation of cultivation progress, and troubles in Aspergillus transportation, so as to improve cultivation efficiency and enhance Cooling effect, the effect of shortening the cooling time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

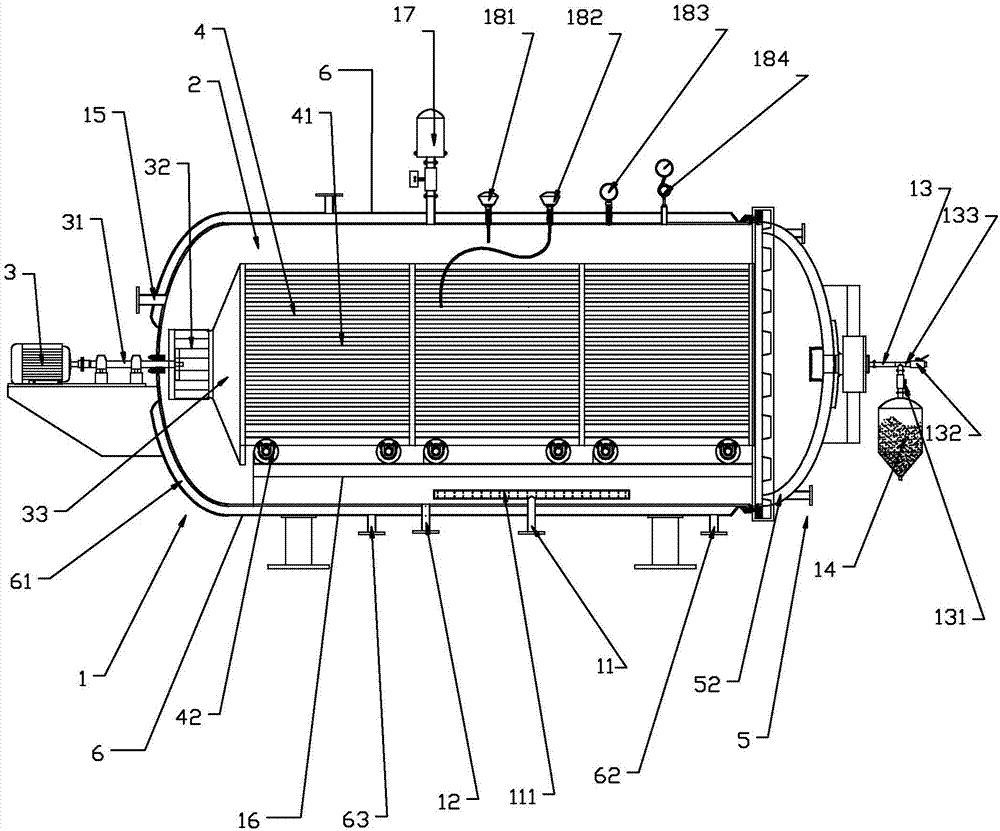

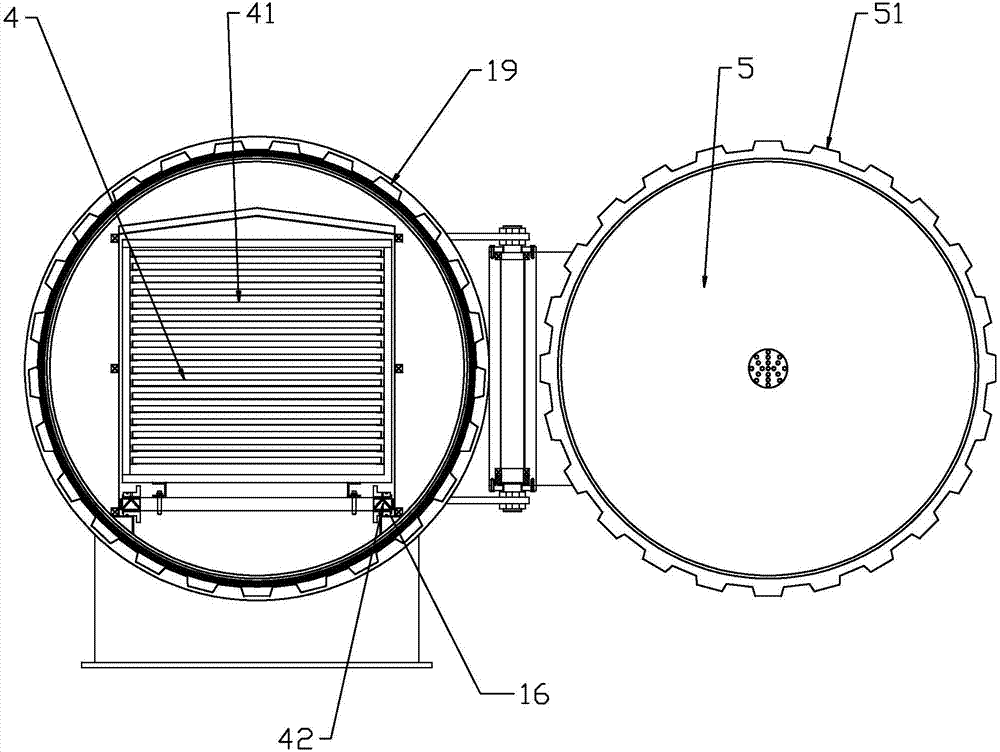

[0027] Such as figure 1 — figure 2 As shown, the present invention discloses an automatic koji planting machine, comprising a tank body 1, the tank body 1 is provided with a strain culture chamber 2, a container for laying culture materials is arranged in the strain culture chamber 2, and the tank body 1 is also provided with There is a sterilization mechanism and a negative pressure inoculation mechanism. The sterilization mechanism includes an airflow inlet channel 11 and an airflow outlet channel 12. One end of the airflow inlet channel 11 communicates with the strain culture chamber 2, and the other end communicates with the steam supply source and the sterile air source respectively. It can also be switched between the steam supply source and the sterile gas source. One end of the air discharge channel 12 is connected to the strain culture chamber 2, and the other end is connected to the gas-liquid collection source. The negative pressure inoculation mechanism includes a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com