Preparation process of ultraviolet-proof functional garment adhesive interlining

A technology of anti-ultraviolet and preparation technology, which is applied in the processing of textile materials, synthetic resin layered products, continuous processing of textile materials, etc. It can solve the problems of unsatisfactory customers, poor anti-ultraviolet effect of interlinings, etc., and achieve excellent washability , good effect, excellent friction resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

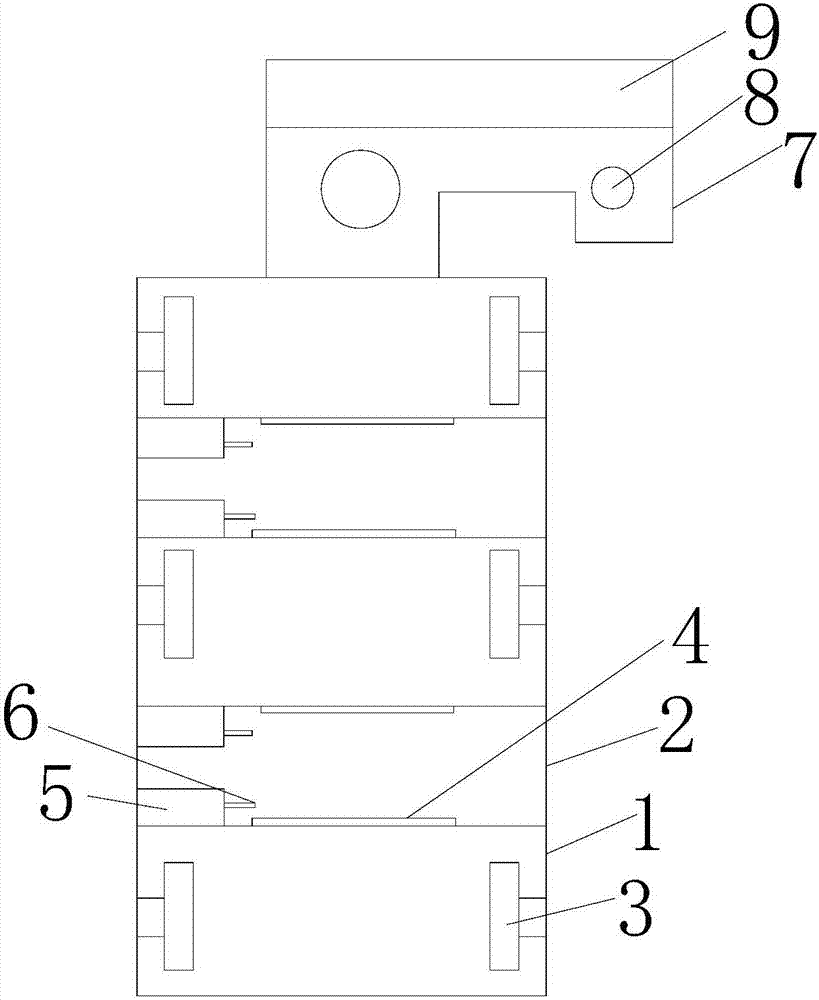

Image

Examples

Embodiment Construction

[0024] The preparation process of a kind of anti-ultraviolet functional clothing adhesive lining of the present invention, comprises the following steps successively:

[0025] Step 1: base fabric weaving: polyester low elastic yarn is used as warp yarn, high elastic anti-ultraviolet polyester yarn is used as weft yarn, warp yarn and weft yarn are weaved by plain weave in warp knitting machine to form base fabric;

[0026] Step 2: Water bath treatment: Submerge the base fabric in a water bath liquid added with alkali, scouring agent and hydrogen peroxide for water bath treatment. The water bath temperature is 30-35°C, and the water bath time is 20-30 minutes. Ultrasonic vibration is used to accelerate the reaction during the water bath process. Spray and clean the residual solution on the surface of the base cloth with clean water at 20-30°C, and finally dehydrate and arrange the shape;

[0027] Step 3: Overflow loose pre-treatment: pre-dry and pre-shrink the base fabric, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com