A method and detection tube for visual detection of benzoyl peroxide in flour

A technology of benzoyl peroxide and flour is applied in the direction of material analysis by observing the influence of chemical indicators, and analysis by chemical reaction of materials, which can solve the problems of complex overall operation and lack of color discrimination. Achieving the effect of high resolution and rich system color changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1. Synthesis of Au nanorod solution:

[0024] Synthesis of seed crystals: In 9.75 mL cetyltrimethylammonium bromide solution (CTAB), add 0.25 mL chloroauric acid solution (9.711 mmol / L), then add 0.6 mL sodium borohydride solution (0.01 mol / L L), after stirring for 30s, settling at 30°C for 1 hour, set aside, the color is tea brown;

[0025] Growth of Au nanorods: In 100 mL cetyltrimethylammonium bromide solution (CTAB), add 5.15 mL chloroauric acid solution (9.711 mmol / L), 0.1 mL silver nitrate solution (0.1 mol / L) , 2 mL of hydrochloric acid solution (1 mol / L), then add 0.8 mL of ascorbic acid solution (0.1 mol / L), mix well, add 0.5 mL of the seed crystal synthesized in step (1), keep it overnight in the dark, and then centrifuge to remove the supernatant, redispersed in 50 mL cetyltrimethylammonium bromide solution (CTAB).

[0026] 2. Synthesis of Au@Ag core-shell nanorods:

[0027] (A) Take 4 mL of the synthesized Au nanorod solution, centrifuge at 12,000 rpm...

Embodiment 2

[0034] 1. Spectrophotometric detection of benzoyl peroxide in plain flour based on Au@Ag core-shell nanorod solution:

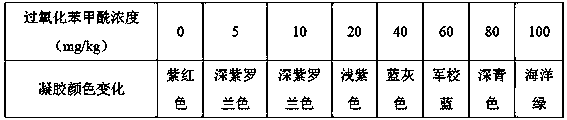

[0035] Take the Au@Ag core-shell structure nanorod solution, dilute it with water, add CTAB solution, and then add 100 µL of plain flour extract containing different concentrations of benzoyl peroxide (0 mg / kg, 20 mg / kg, 40 mg / kg, 60 mg / kg, 80 mg / kg, 100 mg / kg), mix well. The corresponding relationship between the concentration of benzoyl peroxide and the change of the solution color is shown in Table 2; the absorption peak of the solution at 560 nm gradually red shifted to 610 nm.

[0036] Table II

[0037]

[0038] 2. Preparation of gel detection tubes:

[0039] Gel detection tube preparation: 300 µL of Au@Ag core-shell structure nanorod solution was added to the agarose gel solution, and the temperature of the gel water bath was controlled at 40 °C. After mixing, take 100 µL of the mixture into the cap of the detection tube. After standing for 5 min,...

Embodiment 3

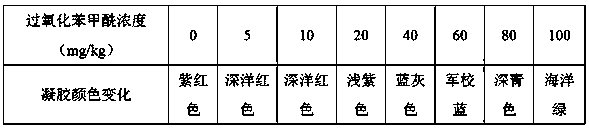

[0041] 1. Preparation of standard color card for detecting benzoyl peroxide by gel detection tube:

[0042] Take different concentrations of 1 mL of benzoyl peroxide ethanol solution (0 μmol / L, 20 μmol / L, 40 μmol / L, 60 μmol / L, 80 μmol / L, 100 μmol / L, 200 μmol / L) into the gel detection tube, cover the lid, place it upside down, and then place it at room temperature. After reacting for 25 minutes, place the gel detection tube upright, and open the lid to take pictures, and obtain the relationship between the concentration of benzoyl peroxide and the color of the gel. change correspondence. Make a standard color card for the detection of benzoyl peroxide in gel test tubes.

[0043] 2. Gel detection tube to detect benzoyl peroxide in high-gluten flour:

[0044] Determination of benzoyl peroxide in high-gluten flour by standard addition method. Weigh 1g of high-gluten flour, add different qualities of benzoyl peroxide, so that the mass concentration of benzoyl peroxide in the flo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com