Organic silicon modified polyurethane sealing agent

A silicone and sealant technology, used in polyurea/polyurethane adhesives, adhesives, adhesive types, etc., can solve the problems of affecting the strength of the sealant, human and environmental hazards, insufficient strength, etc., and increase environmental performance. , not easy to whitish, good sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

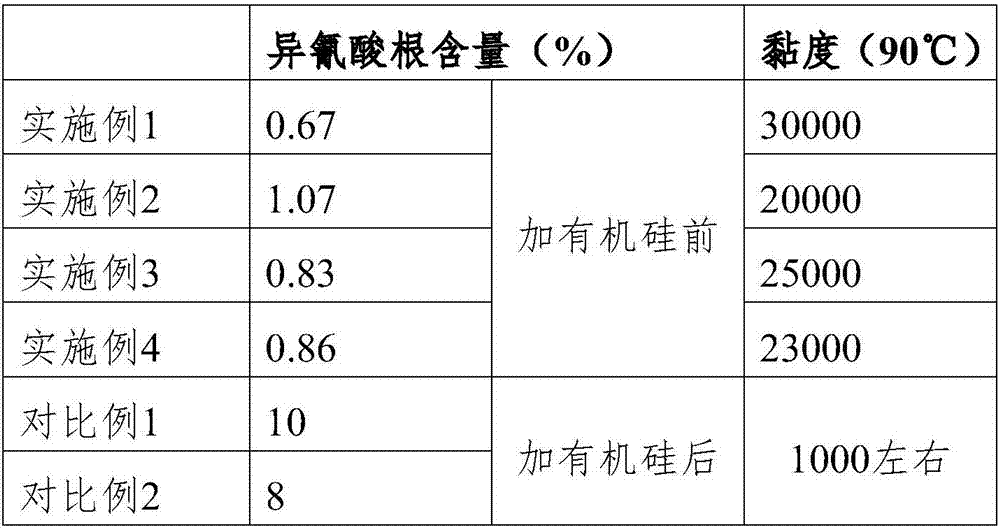

Examples

Embodiment 1

[0030] This example relates to a silicone-modified polyurethane sealant, which is prepared from the following raw materials: 60 g of toluene diisocyanate, 200 g of polyether N220, 200 g of polyether 3050, 3 g of epoxy resin E51, and 20 g of silicone Y-9669.

[0031] Its preparation method comprises the following steps:

[0032] 5) Heat up polyether N220 and polyether 3050 to 120° C., keep for 2 hours, and perform dehydration treatment. After dehydration treatment, cool down polyether N210 and polyether 3050 to 50° C. for use.

[0033] 6) Under the protection of nitrogen, polyether 3050 and N220 are put into toluene diisocyanate successively (at an interval of half an hour) under the condition of 75-80°C and reacted for 2 hours to form a polyurethane prepolymer;

[0034] 3) The polyurethane prepolymer and epoxy resin E51 are reacted for 1 to 1.5 hours at 75 to 80°C under the protection of nitrogen to generate epoxy-modified polyurethane prepolymer (EP-PUR);

[0035] 4) The EP-...

Embodiment 2

[0037] This embodiment relates to a silicone-modified polyurethane sealant, which is prepared from the following raw materials: 100 g of toluene diisocyanate, 470 g of polyether N220, 350 g of polyether N3050, 50 g of silicone Y-9669, and 10 g of epoxy resin E51.

[0038] Its preparation method comprises the following steps:

[0039] 1) Raise the temperature of polyether N220 and polyether 3050 to 120°C respectively, keep it for 2 hours, and perform dehydration treatment. After the dehydration treatment is completed, cool down the temperature of polyether N210 and polyether 3050 to 50°C for use.

[0040] 2) Under the protection of nitrogen, polyether 3050 and N220 are put into toluene diisocyanate successively (with an interval of half an hour) under the condition of 75-80°C and reacted for 2 hours to form a polyurethane prepolymer;

[0041] 3) The polyurethane prepolymer and epoxy resin E51 are reacted for 1 to 1.5 hours at 75 to 80°C under the protection of nitrogen to gener...

Embodiment 3

[0044] This embodiment relates to a silicone-modified polyurethane sealant, which is prepared from the following raw materials: 80 g of toluene diisocyanate, 250 g of polyether N220, 320 g of polyether N3050, 30 g of silicone Y-9669, and 5 g of epoxy resin E51.

[0045] Its preparation method comprises the following steps:

[0046] 1) Raise the temperature of polyether N220 and polyether 3050 to 120°C respectively, keep it for 2 hours, and perform dehydration treatment. After the dehydration treatment is completed, cool down the temperature of polyether N210 and polyether 3050 to 50°C for use.

[0047] 2) Under the protection of nitrogen, polyether 3050 and N220 are put into toluene diisocyanate successively (with an interval of half an hour) under the condition of 75-80°C and reacted for 2 hours to form a polyurethane prepolymer;

[0048] 3) The polyurethane prepolymer and epoxy resin E51 are reacted for 1 to 1.5 hours at 75 to 80°C under the protection of nitrogen to generat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com