A kind of electromagnetic wave absorber using titanium-based metal organic framework material as precursor and preparation method thereof

An organic framework and electromagnetic absorbing technology, which is applied in the preparation of electromagnetic absorbing agents and the field of electromagnetic absorbing agents, can solve the problems of not eradicating electromagnetic waves, etc., and achieve the effects of excellent reflection loss, simple process, and excellent absorbing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The preparation method of the electromagnetic wave absorbing agent using the titanium-based metal organic framework material as the precursor of the present invention comprises the following steps:

[0028] Step 1, preparation of titanium-based metal organic framework material precursor: take 18ml of N,N-dimethylformamide and 2ml of methanol respectively in a clean beaker, mix and stir evenly, and then add 1.0g of terephthalic acid to it, Mix and stir evenly, and finally add 1.2ml tetraisopropyl titanate to it, mix and stir evenly, transfer the mixture to a 100ml reactor and react at 150°C for 15 hours; filter and wash the product after the reaction , drying treatment;

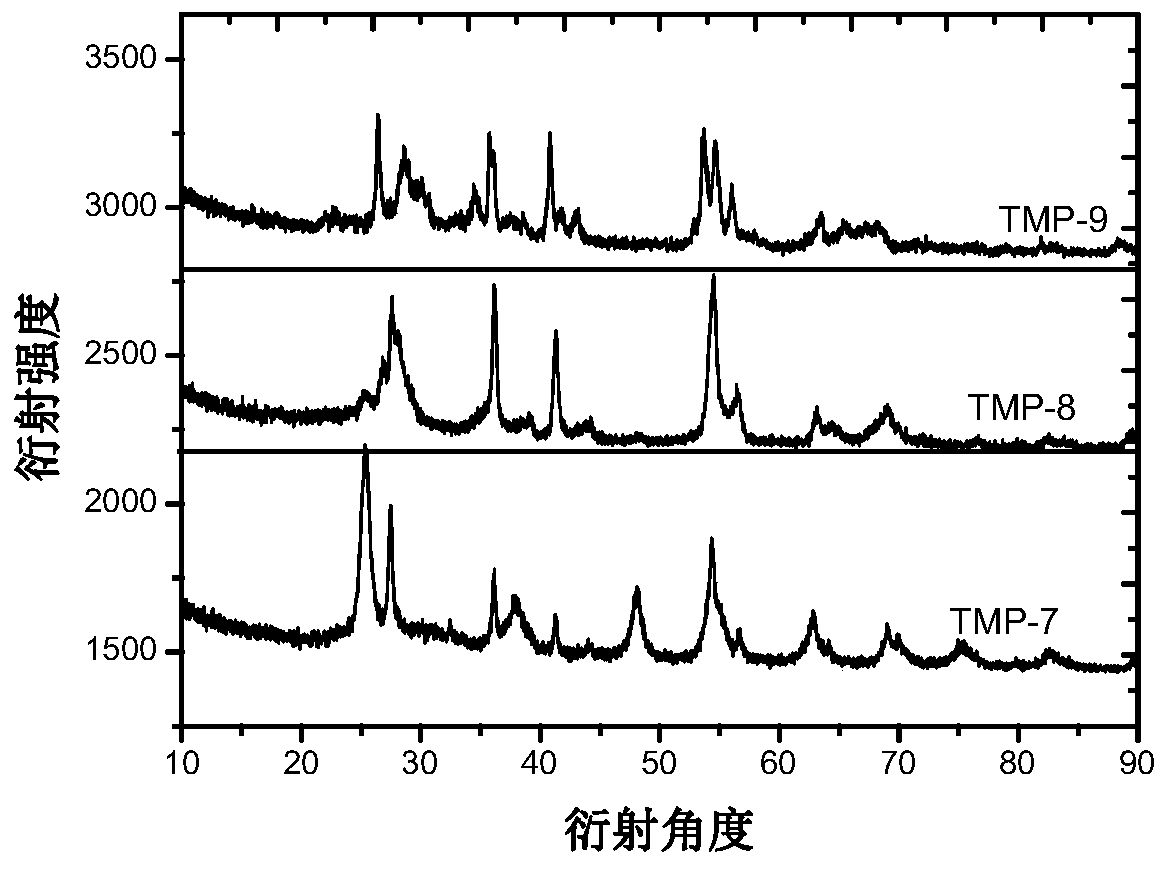

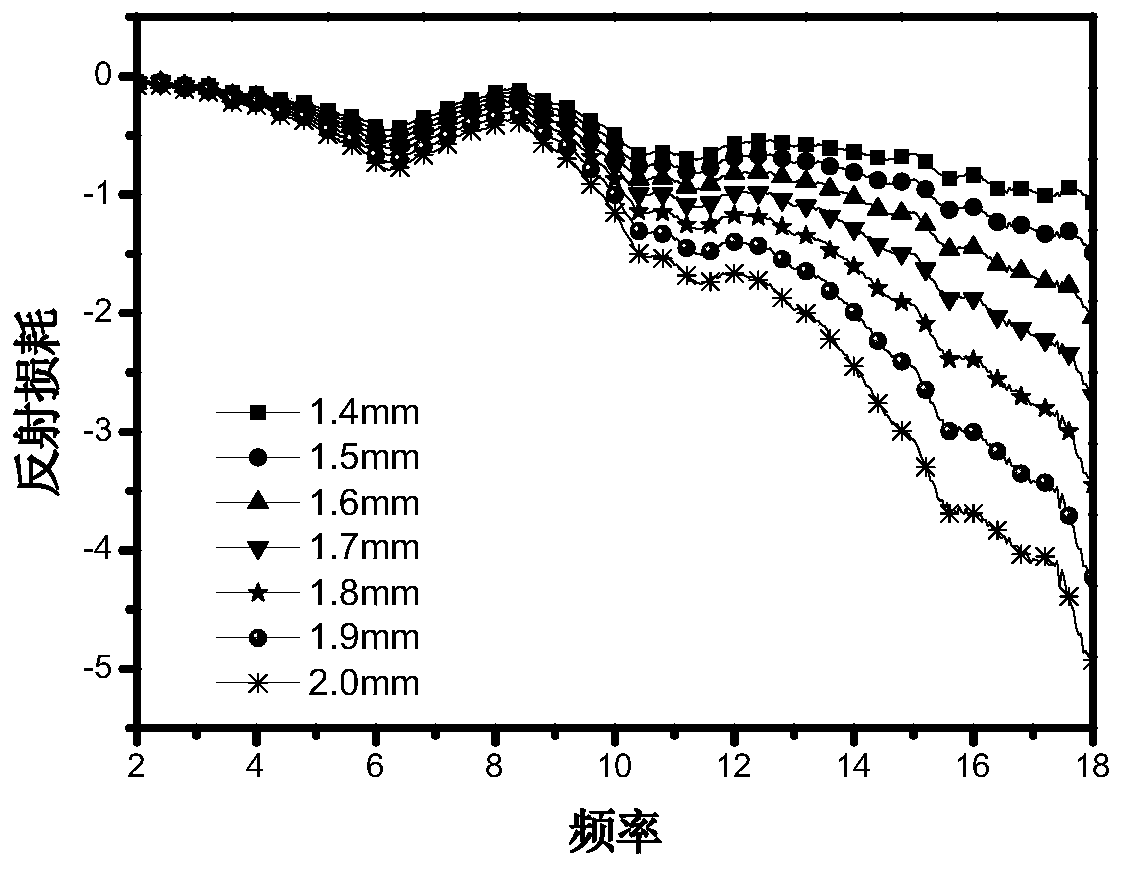

[0029] In step 2, the precursor product of titanium-based metal organic framework material obtained in step 1 is calcined at high temperature under a nitrogen atmosphere to carbonize the titanium MOF; the calcining temperature is 700°C, the heating rate is 2°C / min, and the holding time is 4h. Porous Ti...

Embodiment 2

[0031] The preparation method of the electromagnetic wave absorbing agent using the titanium-based metal organic framework material as the precursor of the present invention comprises the following steps:

[0032] Step 1, preparation of titanium-based metal organic framework material precursor: take 18ml of N,N-dimethylformamide and 2ml of methanol respectively in a clean beaker, mix and stir evenly, and then add 1.0g of terephthalic acid to it, Mix and stir evenly, and finally add 1.2ml tetraisopropyl titanate to it, mix and stir evenly, transfer the mixture to a 100ml reactor and react at 150°C for 15 hours; filter and wash the product after the reaction , drying treatment;

[0033] In step 2, the precursor product of titanium-based metal organic framework material obtained in step 1 is calcined at high temperature under a nitrogen atmosphere to carbonize the titanium MOF; the calcining temperature is 800°C, the heating rate is 2°C / min, and the holding time is 4h. Porous Ti...

Embodiment 3

[0035] The preparation method of the electromagnetic wave absorbing agent using the titanium-based metal organic framework material as the precursor of the present invention comprises the following steps:

[0036] Step 1, preparation of titanium-based metal organic framework material precursor: take 18ml of N,N-dimethylformamide and 2ml of methanol respectively in a clean beaker, mix and stir evenly, and then add 1.0g of terephthalic acid to it, Mix and stir evenly, and finally add 1.2ml tetraisopropyl titanate to it, mix and stir evenly, transfer the mixture to a 100ml reactor and react at 150°C for 15 hours; filter and wash the product after the reaction , drying treatment;

[0037] In step 2, the precursor product of titanium-based metal organic framework material obtained in step 1 is calcined at high temperature under a nitrogen atmosphere to carbonize the titanium MOF; the calcining temperature is 900°C, the heating rate is 2°C / min, and the holding time is 4h. Porous Ti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| optical bandwidth | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com