High-solubility cod protein

A technology for cod protein and cod, which is applied in the field of highly soluble cod protein, can solve the problems of difficulty in diversified development of protein products, unfavorable absorption, reduced nutrient utilization rate and application value, etc., and achieves reasonable amino acid ratio and improved solubility. , good foaming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] A preparation method of highly soluble cod protein, characterized in that the method steps are as follows:

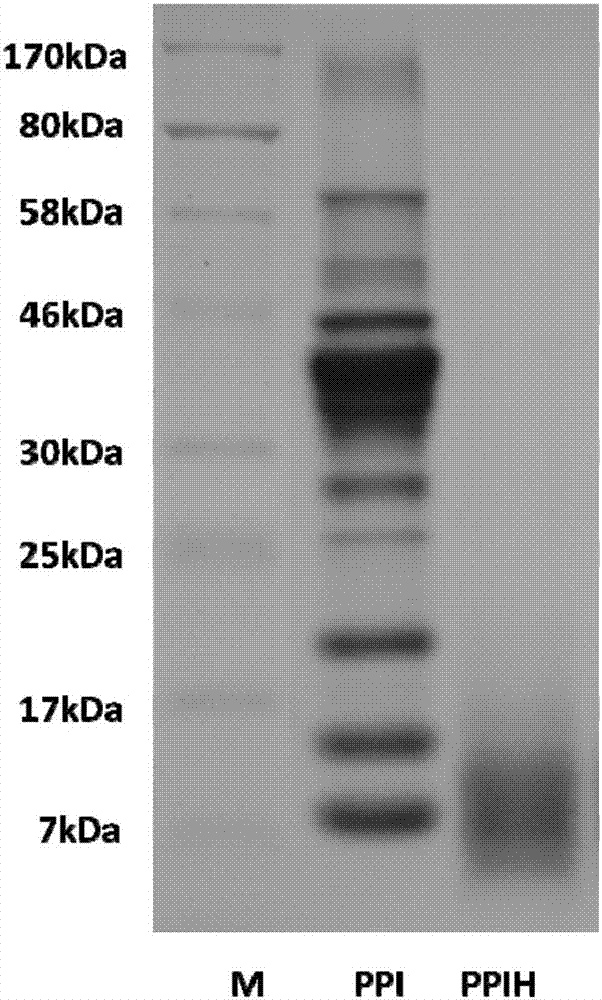

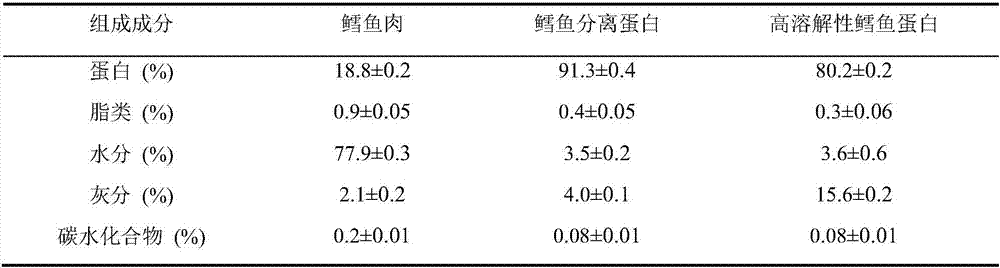

[0018] A) Preparation of cod protein isolate: use cod as raw material, remove the head, peel off the skin, clean the internal organs, wash with ice water, remove the cod meat, add water and homogenize it, adjust the pH to 11.0 with sodium hydroxide solution, and collect the supernatant by centrifugation , adjusting the pH to 5.0 with hydrochloric acid solution, centrifuging, collecting the precipitate, redissolving with water, adjusting the pH to neutral with sodium hydroxide solution, vacuum freeze-drying and freeze-drying to obtain cod protein isolate.

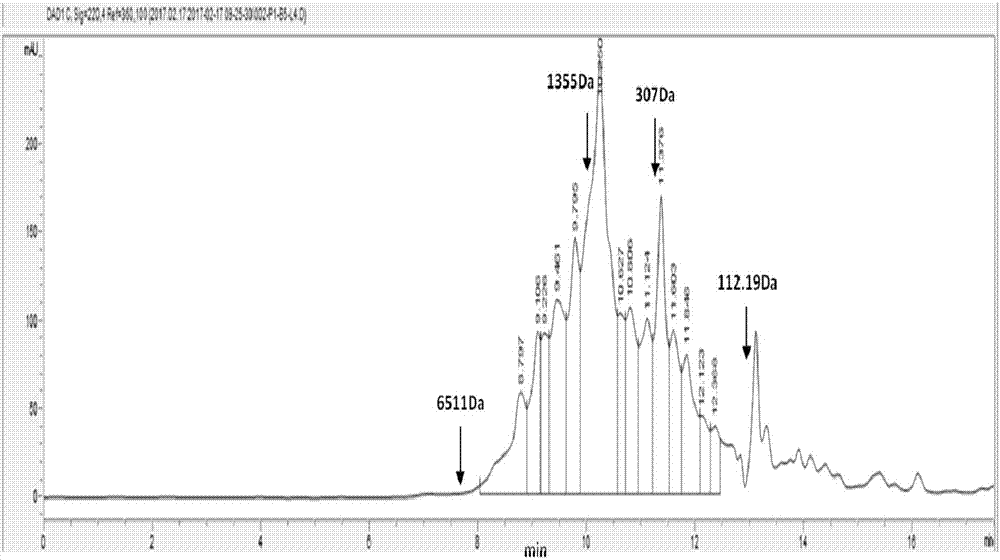

[0019] B) enzymatic modification: cod protein isolate is dissolved in water according to the ratio of 4% (w / v) to make cod protein dispersion, adjust pH to 7.8 with sodium hydroxide solution, then add neutral protease 3100U / g, in Shaking and hydrolyzing in a constant temperature water bath at 50°C for 5 hours t...

Embodiment 2

[0040] A preparation method of highly soluble cod protein, characterized in that the method steps are as follows:

[0041] A) Preparation of cod protein isolate: use cod as raw material, remove the head, peel off the skin, clean the internal organs, wash with ice water, remove the cod meat, add water and homogenize it, adjust the pH to 11.0 with sodium hydroxide solution, and collect the supernatant by centrifugation , adjusting the pH to 5.0 with hydrochloric acid solution, centrifuging, collecting the precipitate, redissolving with water, adjusting the pH to neutral with sodium hydroxide solution, vacuum freeze-drying and freeze-drying to obtain cod protein isolate.

[0042] B) enzymatic modification: cod protein isolate is dissolved in water according to the ratio of 4% (w / v) to make cod protein dispersion, adjust pH to 8.0 with sodium hydroxide solution, then add neutral protease 3000U / g, in Shaking and hydrolyzing in a constant temperature water bath at 50°C for 4.5 hours...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

| Average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com