Nitridation controllable zero-pollution ion nitriding device

An ion nitriding, zero-pollution technology, applied in metal material coating process, coating, solid-state diffusion coating, etc., can solve the problems of non-adjustable anode-cathode spacing, uncontrollable nitriding, ammonia pollution, etc., to achieve Effects of zero-pollution ion nitriding, shortening production cycle, and solving pollution problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

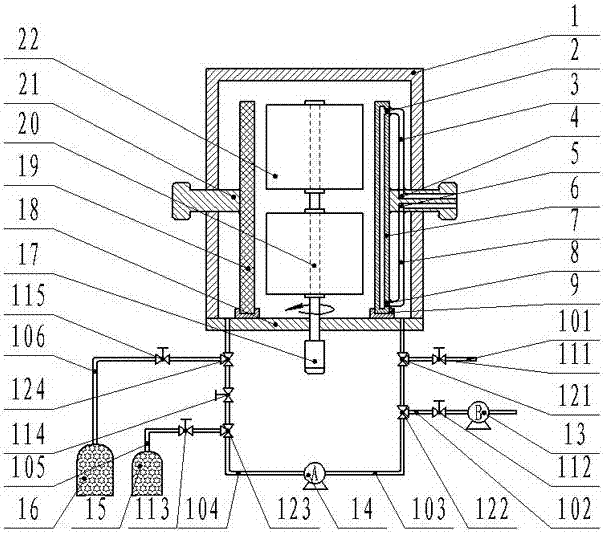

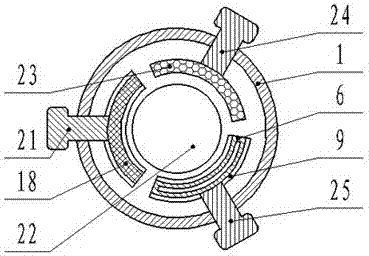

[0030] Such as figure 1 and figure 2 As shown, a zero-pollution ion nitriding device with controllable nitriding includes a furnace body 1, a furnace chassis 18, a transmission system, an adjustable cathode system, a rapid cooling system, an adjustable anode system, and a zero-pollution gas circulation system. The furnace body 1 is placed directly above the furnace chassis 18 to form a nitriding chamber, and the bottom of the nitriding chamber is provided with an air inlet and an air outlet; the transmission system is fixed in the middle of the furnace chassis 18; the adjustable cathode system, the rapid cooling system and the adjustable anode system are placed In the middle of the nitriding chamber; the zero-pollution gas circulation system is placed in the outer lower part of the furnace chassis 18.

[0031] The transmission system includes a counterclockwise motor 17, a cathode support 20, and a workpiece 22. The counterclockwise motor 17 is connected to the cathode suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com