Electromigration resistance silver nano wire composite film and preparation method thereof

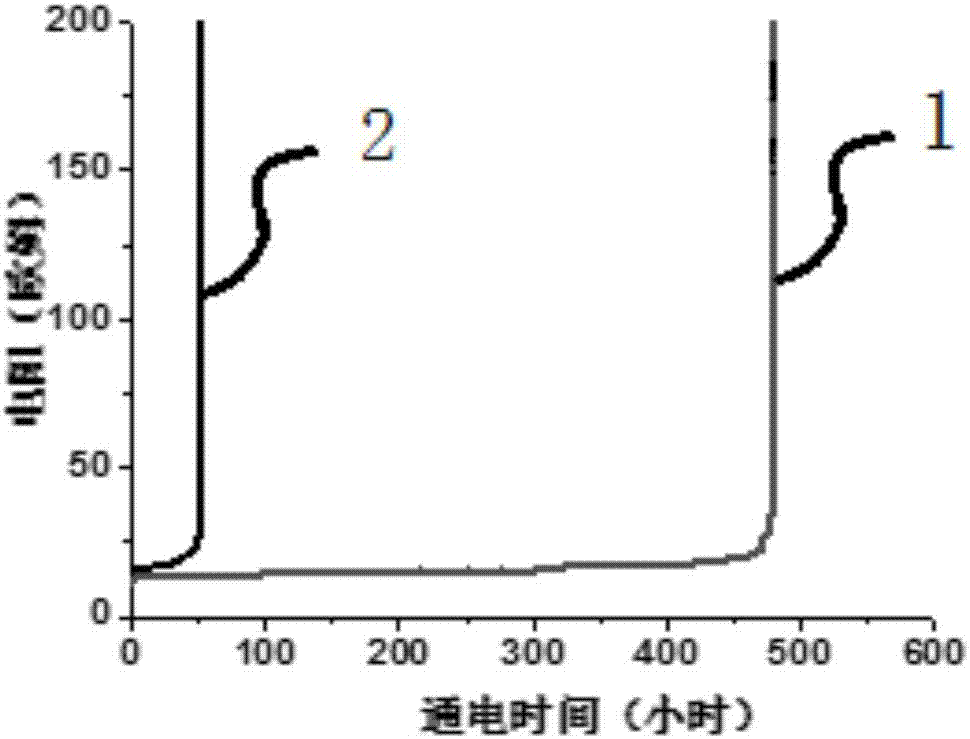

A technology of silver nanowires and composite films, which is applied in the manufacture of cables/conductors, equipment for manufacturing conductive/semiconductive layers, circuits, etc. The protective layer of graphene sheets is not dense, etc., to achieve the effect of enhancing the ability of anti-electromigration, good compactness, and enhancing the ability of electromigration resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Example 1 Preparation of Polyvinyl Alcohol Composite Silver Nanowire Transparent Conductive Film

[0019] 1) Disperse silver nanowires with a diameter of about 35nm in isopropanol, scrape-coat the film on a glass substrate, form a silver nanowire accumulation film on the substrate, and obtain a transparent conductive film of silver nanowires;

[0020] 2) dissolving polyvinyl alcohol in water, the concentration is 2wt%;

[0021] 3) spin-coat the polyvinyl alcohol solution on the surface of the prepared silver nanowire film, the rotation speed is 3000rpm, and the rotation time is 60s;

[0022] 4) Place the sample on a hot stage and dry it at 110°C for 10 minutes to remove the solvent in the polymer protective layer to obtain a silver nanowire composite film;

[0023] 5) When passing current into the silver nanowire composite film, place the current injection point on the polymer protective layer.

Embodiment 2

[0024] Embodiment 2 prepares chitosan composite silver nanowire transparent conductive film

[0025] 1) Disperse silver nanowires with a diameter of about 35nm in isopropanol, scrape-coat the film on a glass substrate, form a silver nanowire accumulation film on the substrate, and obtain a transparent conductive film of silver nanowires;

[0026] 2) dissolving the complex of chitosan and ascorbic acid in water, the concentration is 1wt%;

[0027] 3) Spin-coat the chitosan solution on the surface of the prepared silver nanowire film, the rotation speed is 3000rpm, and the rotation time is 60s;

[0028] 4) Place the sample on a hot stage and dry it at 110°C for 10 minutes to remove the solvent in the polymer protective layer to obtain a silver nanowire composite film;

[0029] 5) When passing current into the silver nanowire composite film, place the current injection point on the polymer protective layer.

Embodiment 3

[0031] 1) Dispersing silver nanowires with a diameter of about 35nm in isopropanol;

[0032] 2) dissolving the compound of chitosan and lactic acid in water, the concentration is 1wt%;

[0033] 3) Add the chitosan solution prepared in step 2 to the silver nanowire dispersion in step 1, mix evenly, and scrape the coating film on the glass substrate;

[0034] 4) Place the sample on a hot stage and dry it at 110°C for 10 minutes to remove the solvent in the polymer protective layer to obtain a silver nanowire composite film;

[0035] 5) When passing current into the silver nanowire composite film, place the current injection point on the polymer protective layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com