Semiconductor chalcogenide-containing composite semi-permeable membrane used for water evaporation by light, preparation method and purpose thereof

A chalcogenide compound, composite semipermeable membrane technology, applied in semipermeable membrane separation, chemical instruments and methods, general water supply saving, etc., can solve the problem of light-to-heat conversion efficiency of only 24%, limitation, etc., to achieve light-to-heat conversion effect Good, low cost, good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

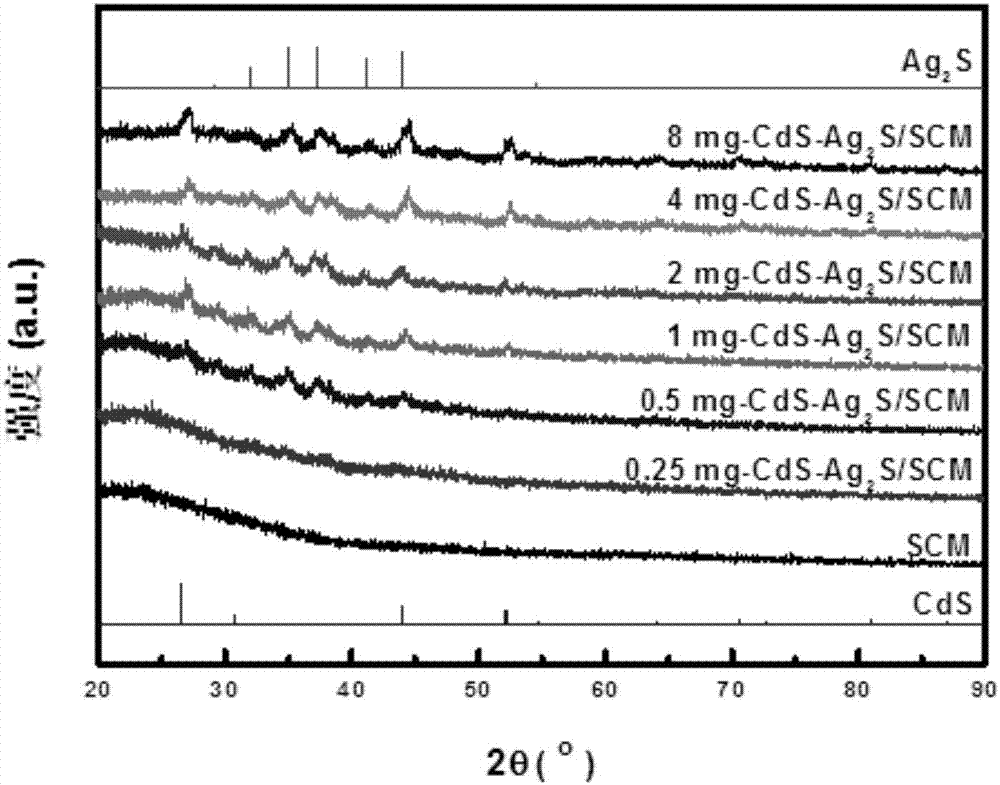

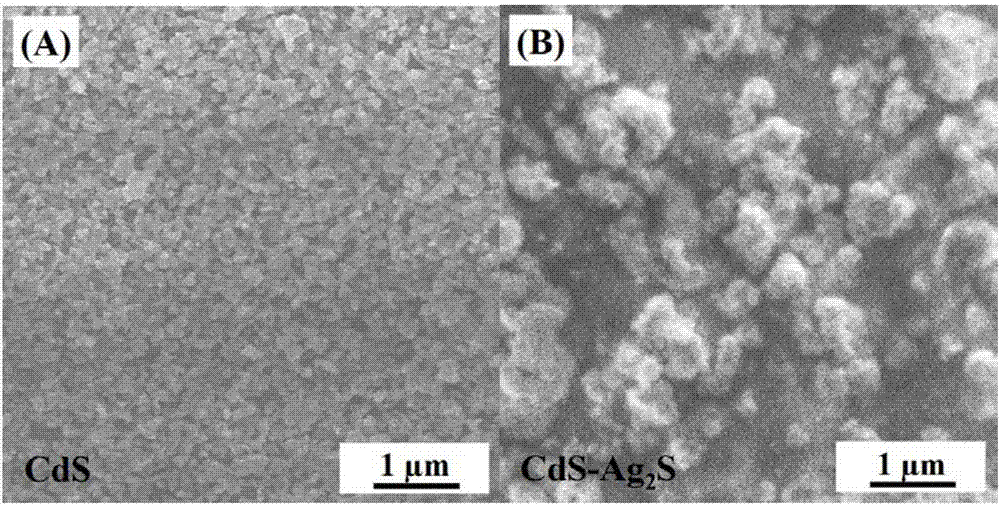

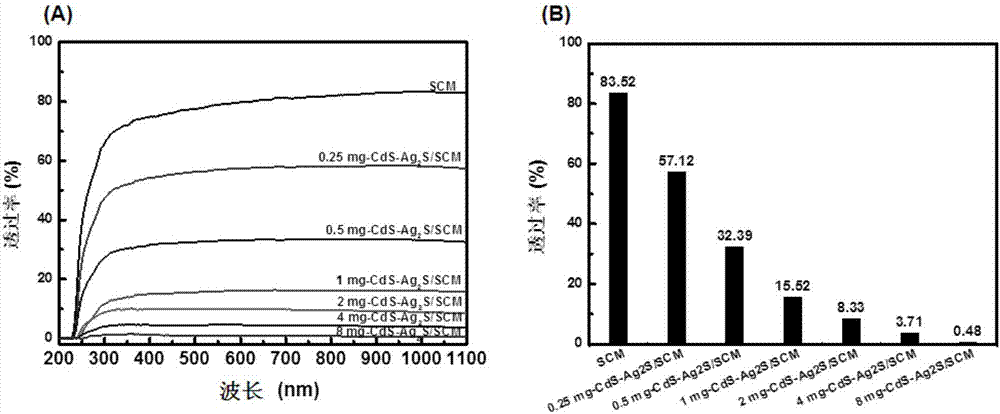

[0034] Add 3.375 mg of CdS to 6 mL of the above-mentioned semipermeable membrane precursor solution, and stir mechanically for 15 minutes to obtain a uniformly mixed mixed solution; take out 2 mL of the mixed solution, add it to the bottom of a 500 mL beaker with a diameter of 75 mm, let it dry naturally to form a film, and cut it A semiconductor CdS-based semipermeable membrane with a content of 0.25 mg was prepared for a circular thin film with a diameter of 35 mm. The prepared semiconductor CdS-based semi-permeable membrane was placed in (0.5mol / L) silver nitrate solution and soaked for 15 minutes, and it was taken out to successfully prepare a semiconductor-containing CdS-Ag with a thickness of about 150 μm and a content of about 0.25 mg. 2 S composite semipermeable membrane.

Embodiment 2

[0036] Add 6.75mg of CdS to 6mL of the above semipermeable membrane precursor solution, and mechanically stir for 15min to obtain a uniformly mixed mixed solution; take out 2mL of the mixed solution, add it to the bottom of a 500mL beaker with a diameter of 75mm, let it dry naturally to form a film, and cut it A semiconductor CdS-based semipermeable membrane with a content of 0.5 mg was prepared for a circular thin film with a diameter of 35 mm. The prepared semiconductor CdS-based semi-permeable membrane was placed in (0.5mol / L) silver nitrate solution and soaked for 15 minutes, and it was taken out, and a semiconductor-containing CdS-Ag with a thickness of about 150 μm and a content of about 0.5 mg was successfully prepared. 2 S composite semipermeable membrane.

Embodiment 3

[0038] Add 13.5 mg of CdS to 6 mL of the above semi-permeable membrane precursor solution, and mechanically stir for 15 minutes to obtain a uniformly mixed mixed solution; take out 2 mL of the mixed solution, add it to the bottom of a 500 mL beaker with a diameter of 75 mm, let it dry naturally to form a film, and cut it A semiconductor CdS-based semipermeable membrane with a content of 1 mg was prepared as a circular thin film with a diameter of 35 mm. The prepared semiconductor CdS-based semi-permeable membrane was placed in (0.5mol / L) silver nitrate solution and soaked for 15 minutes, and it was taken out to successfully prepare a semiconductor-containing CdS-Ag with a thickness of about 150 μm and a content of about 1 mg. 2 S composite semipermeable membrane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com