Automatic continuous foaming molding production line

A foam molding and production line technology, which is applied in the control of pouring molten metal from a casting ladle, manufacturing tools, metal processing equipment, etc. The effect of improving production efficiency, simple structure and easy promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The embodiments are described below with reference to the drawings. The embodiments shown below do not limit the content of the invention described in the claims in any way. In addition, all the contents of the configuration shown in the embodiments below are not limited to the invention described in the claims. Necessary for the solution.

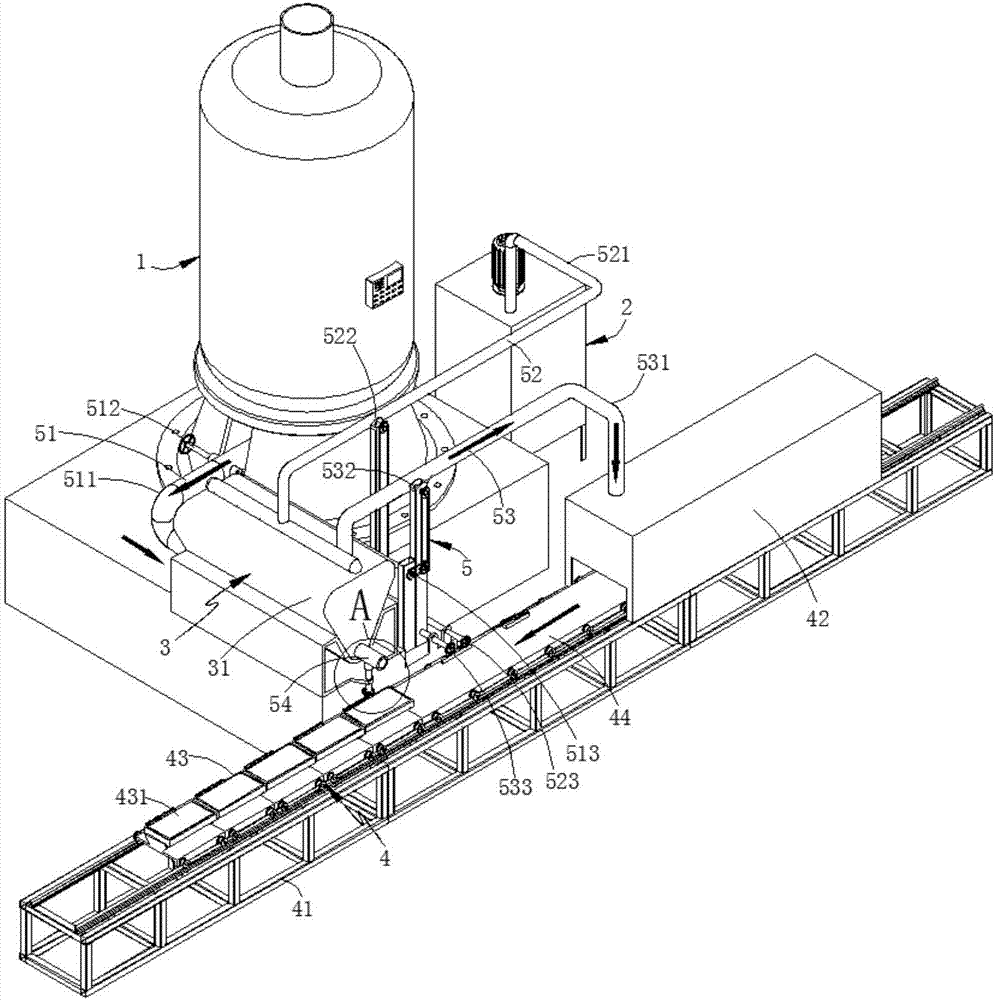

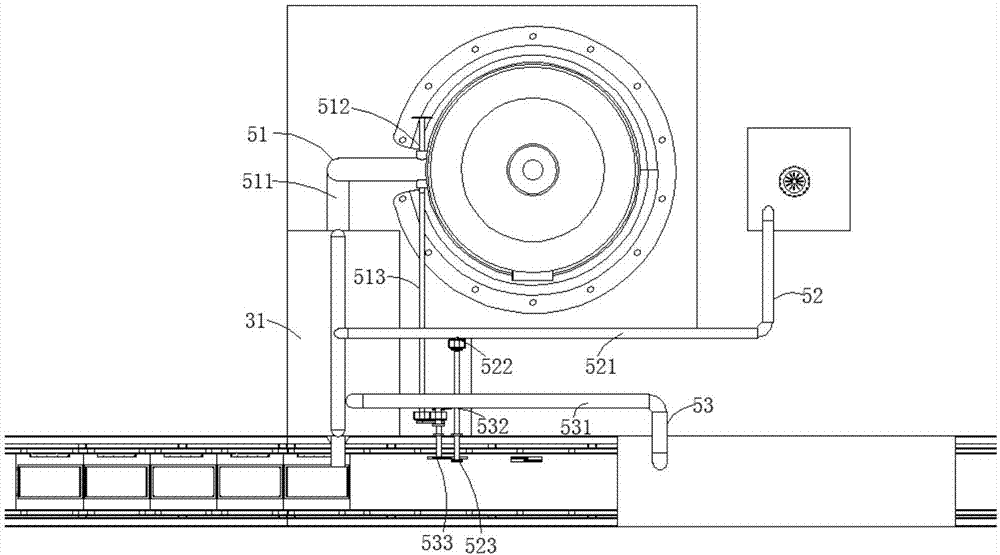

[0044] Such as figure 1 , 2 As shown, an automated continuous foam molding production line includes a foam holding furnace 1, a nitrogen supply assembly 2, and also includes:

[0045] The secondary foaming mechanism 3, the secondary foaming mechanism 3 includes a foaming bin 31 for buffering the molten aluminum that can be cast by a plurality of molding components 43, and the foaming bin 31 is respectively connected to the foaming holding furnace 1, The supply assembly 2 is connected; the molten aluminum flows into the secondary foaming mechanism 3 through the foaming and holding furnace 1 intermittently. After the inflow of the molten a...

Embodiment 2

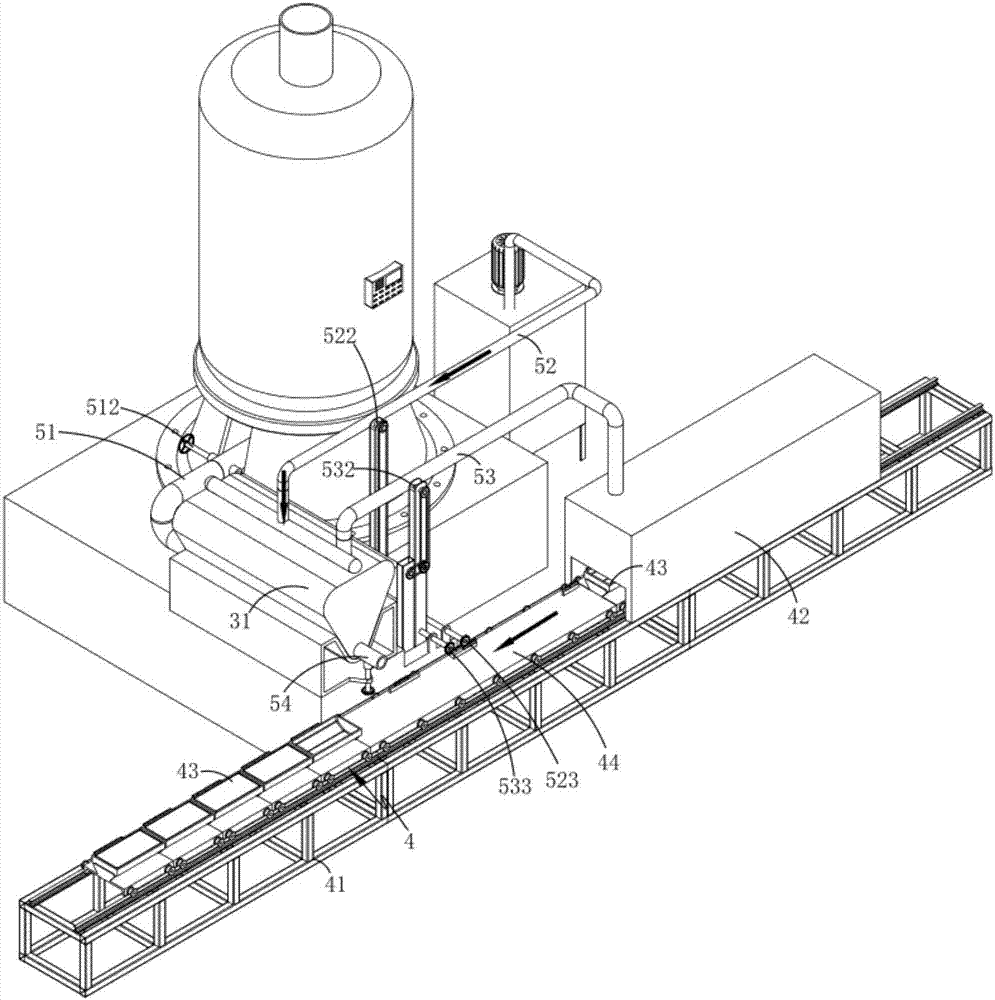

[0060] The components that are the same as or corresponding to those in the first embodiment use the reference numerals corresponding to the first embodiment. For the sake of simplicity, only the differences from the first embodiment are described below. The difference between the second embodiment and the first embodiment is: Picture 10 , 11 As shown, the secondary foaming mechanism 3 further includes a foaming component 32 fixedly arranged on the foaming bin 3 and communicating with the gas delivery pipe 521, and the foaming component 32 is disposed in the foaming bin 31 Inside; the foaming bin 31 is set up in an inverted triangle. During the foaming process, the foaming device 322 inside the aluminum liquid performs gas foaming, and the excess gas is used to form a movement structure in which bubbles move upwards from the bottom of the inverted triangle , To promote uniform foaming of molten aluminum and improve product quality.

[0061] Further, as Picture 10 , 11 12. The f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com