Method for manufacturing gasoline filter through laser welding

A laser welding and filter technology, used in laser welding equipment, welding equipment, manufacturing tools, etc., can solve the problems of substandard mechanical properties of joints, large welding deformation, and low production efficiency, and achieve the optimization of laser welding process parameters, The effect of eliminating pores and inclusions and ensuring the welding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

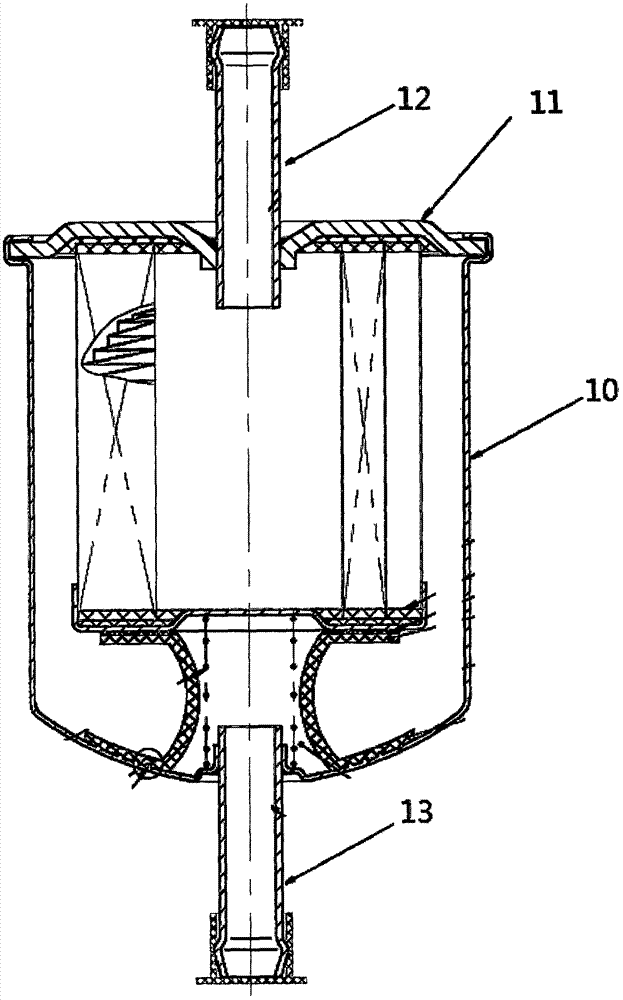

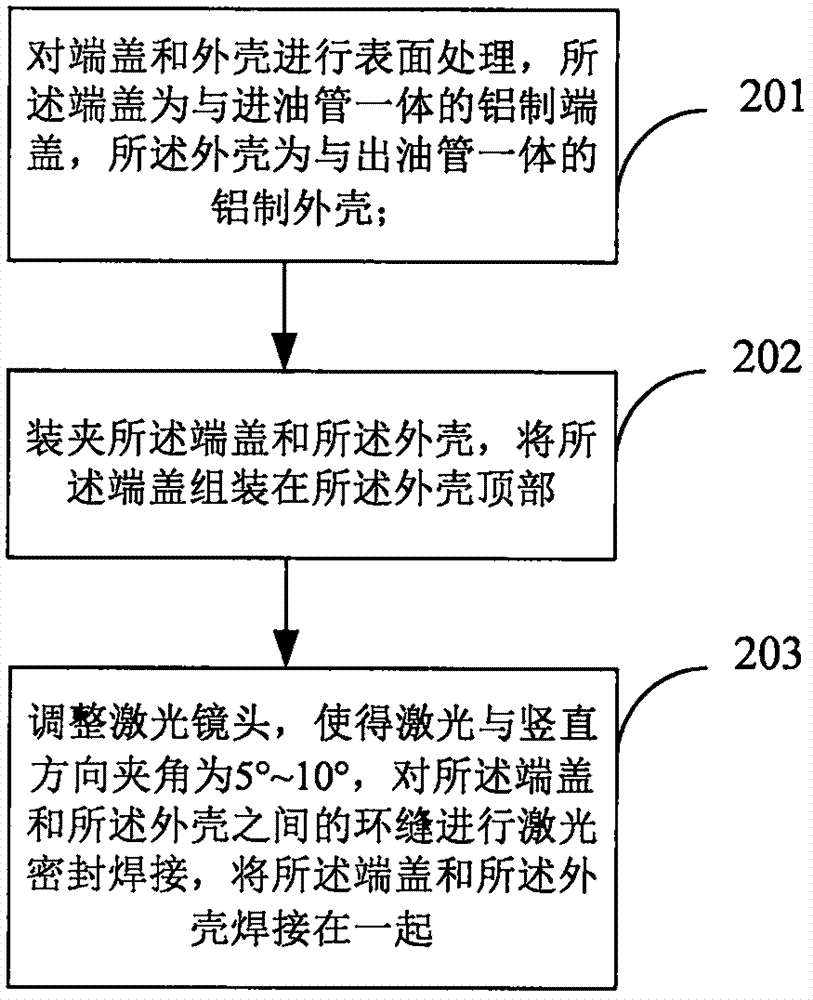

[0055] The laser sealing welding process of the pure aluminum filter housing, the steps are:

[0056] 1) Preparation before welding: Since the stamped workpiece has a lot of oil stains and oxide layers during transportation, it will have a great impact on the laser welding process, so it needs to be washed with acid and alkali before welding. First soak in 8% NaOH aqueous solution at 40°C for 5 minutes, rinse with flowing water, then soak with 30% HNO3 at room temperature for 3 minutes, and finally rinse with water. Dry the workpiece thoroughly with a hair dryer before proceeding to the next step.

[0057] 2) Clamping: Before clamping, select the surface of the workpiece to be flat and free of misalignment, and the weld assembly gap shall not be greater than 0.1mm. After the shell and end cap are assembled manually, the shell is clamped with claw discs, and the weld seam to be welded is reserved.

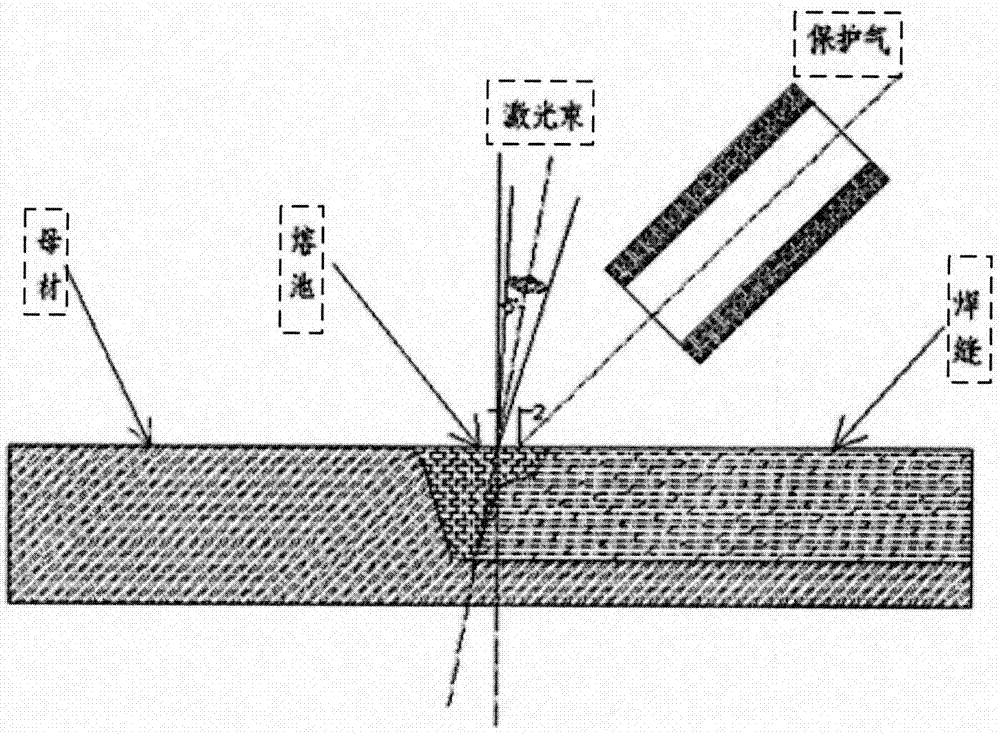

[0058] 3) Laser spot welding positioning: Laser spot welding is performed on ...

Embodiment 2

[0061] The laser sealing welding process of the pure aluminum filter housing, the steps are:

[0062] 1) Preparation before welding: Since the stamped workpiece has a lot of oil stains and oxide layers during transportation, it will have a great impact on the laser welding process, so it needs to be washed with acid and alkali before welding. First soak in 8% NaOH aqueous solution at 40° for 5 minutes, rinse with flowing water, then soak with 30% HNO3 at room temperature for 3 minutes, and finally rinse with water. Dry the workpiece thoroughly with a hair dryer before proceeding to the next step.

[0063] 2) Clamping: Before clamping, select the surface of the workpiece to be flat and free of misalignment, and the weld assembly gap shall not be greater than 0.1mm. After the shell and end cap are assembled manually, the shell is clamped with claw discs, and the weld seam to be welded is reserved.

[0064] 3) Laser spot welding positioning: Laser spot welding is performed on t...

Embodiment 3

[0067] The laser sealing welding process of the pure aluminum filter housing, the steps are:

[0068] 1) Preparation before welding: Since the stamped workpiece has a lot of oil stains and oxide layers during transportation, it will have a great impact on the laser welding process, so it needs to be washed with acid and alkali before welding. First soak in 8% NaOH aqueous solution at 40° for 5 minutes, rinse with flowing water, then soak with 30% HNO3 at room temperature for 3 minutes, and finally rinse with water. Dry the workpiece thoroughly with a hair dryer before proceeding to the next step.

[0069] 2) Clamping: Before clamping, select the surface of the workpiece to be flat and free of misalignment, and the weld assembly gap shall not be greater than 0.1mm. After the shell and end cap are assembled manually, the shell is clamped with claw discs, and the weld seam to be welded is reserved.

[0070] 3) Laser sealing welding: Since the assembly of the workpiece is relati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com