Disc type sludge drying system based on cascade utilization of energy

A sludge drying and disc technology, which is applied in sludge treatment, water/sludge/sewage treatment, dehydration/drying/thickened sludge treatment, etc., can solve the high risk of explosion, low energy utilization rate, scraping Low dust efficiency and other issues to achieve the effect of avoiding explosion, good explosion-proof effect and saving energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

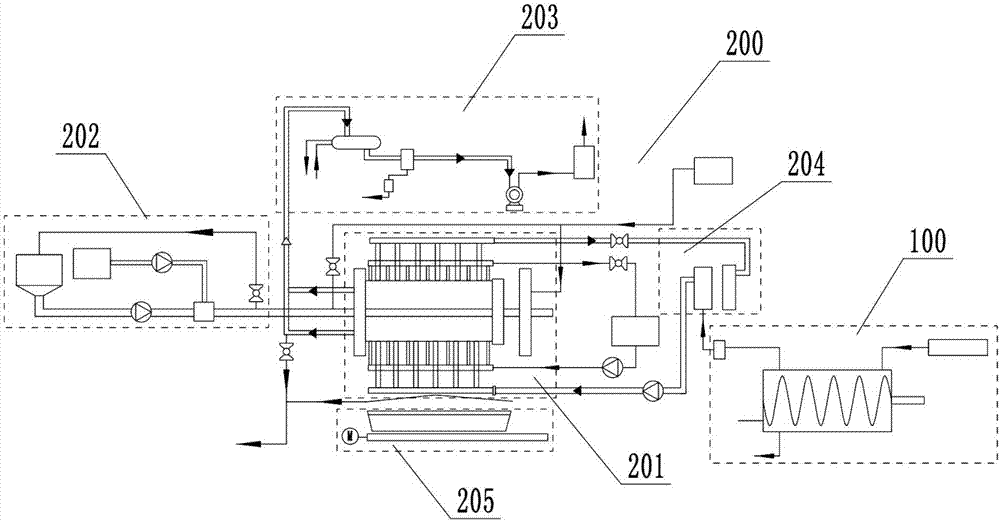

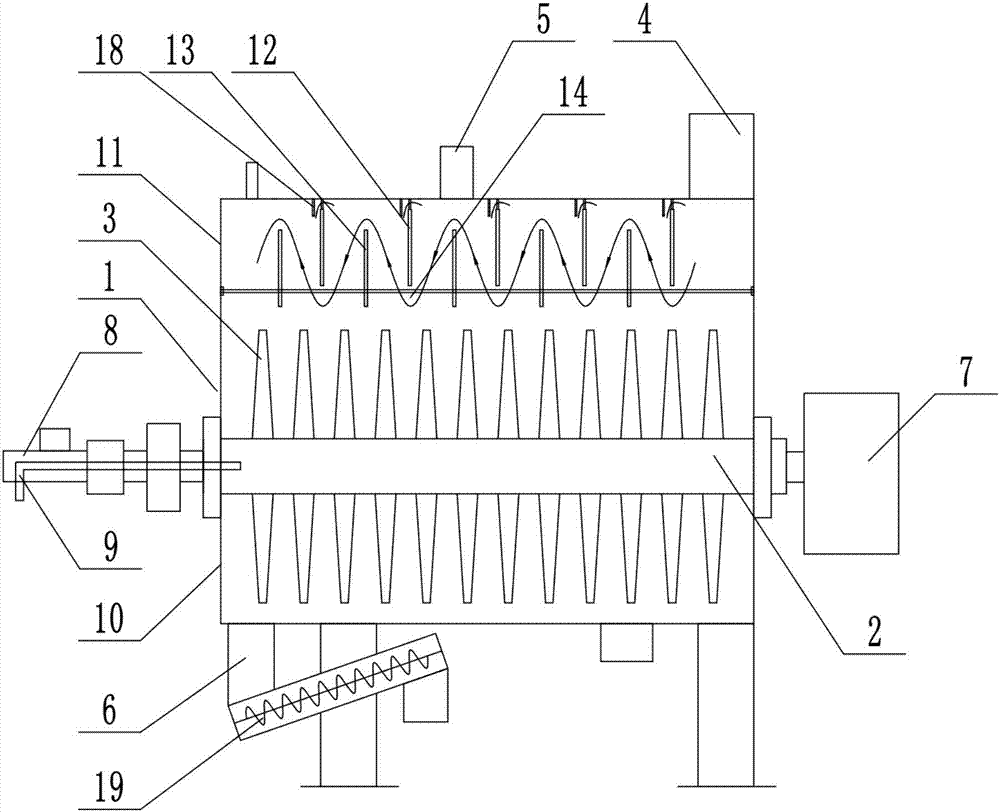

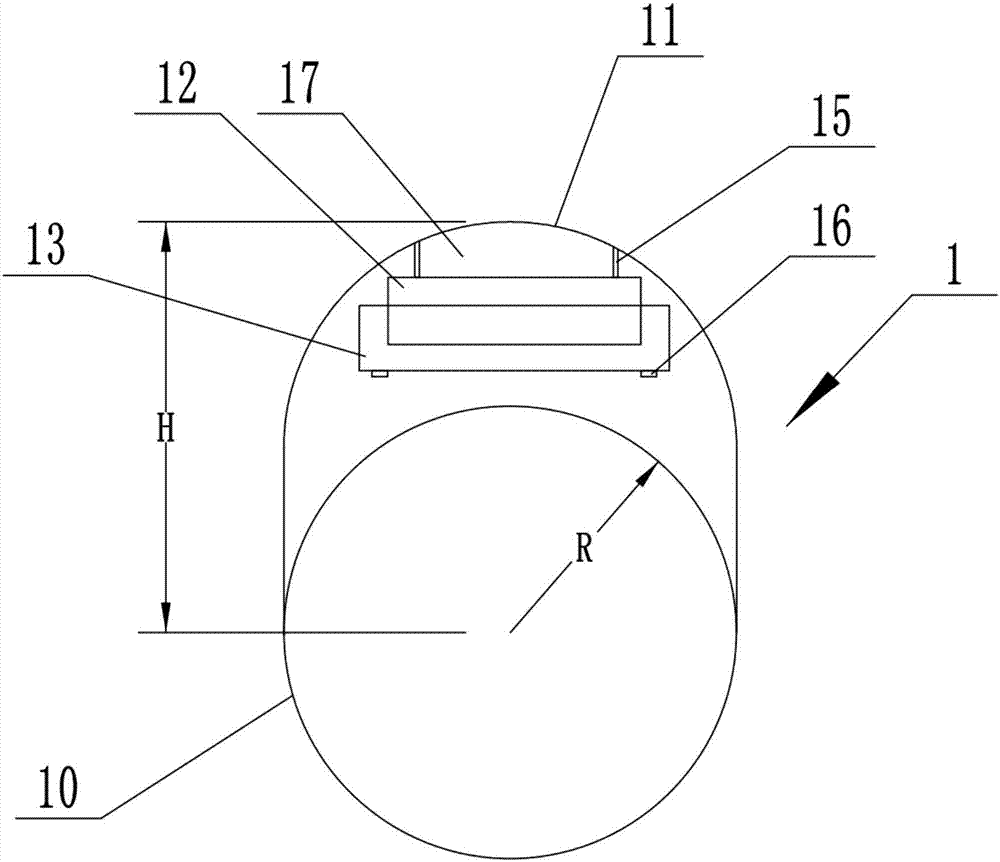

[0032] Such as figure 1 As shown, the disk sludge drying system based on energy cascade utilization in this embodiment includes a disk drying system 100 and a filter press drying system 200. The disk drying system 100 includes a housing 1, and in the housing 1 A stirring shaft 2 is installed, and a disc plate 3 is installed separately on the stirring shaft 2. The top of the shell 1 is provided with a sludge inlet 4, a steam outlet 5, and a dry sludge outlet 6 at the bottom. The stirring shaft 2 is formed by a Driven by a stirring motor 7, the stirring shaft 2 is a hollow structure, one end of which is a hot steam inlet 8 and a condensed water outlet pipe 9 is inserted; the filter press drying system 200 includes a filter press system 201 and a mud inlet connected to the filter press system 201 System 202, vacuum system 203, hot water circul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com